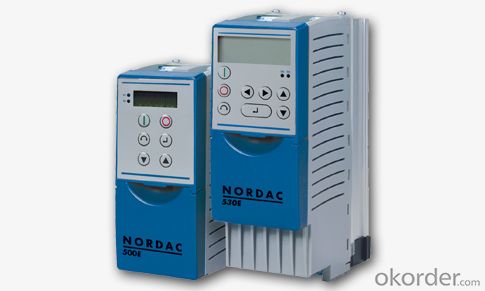

drive electronics SK 500E - Modular frequency inverter

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

SK 500E - Modular frequency inverter

Following its introduction in the market the SK 500E product series has become successfully established and now the power range has been extended to 90kW. This extends the success factors of these components to a wider field of applications.

Modular compact inverter: SK 500E

With the SK 500E series of frequency inverters, Getriebebau NORD offers intelligent and costeffective drive solutions with scaleable equipment options, which are all fully compatible with regard to motor performance range, supply voltage and sizes. The basis for all models is a well-equipped basic unit with expansion possibilities through optional modules. SK 500E inverters are suitable for all application areas and can be easily adapted to specific requirements with plug-in technology units.

Performance grading:

The SK 500E product series offers a wide range of features which are necessary for application-specific drive solutions. Through different configuration levels, these can be used "in the same box". The inverters include the following functions, which are state-of-the-art for industrial applications.

"Safe stop" (STO) as per EN ISO 13849-1 Cat.4,

Performance level e EN 61508 SIL3CANopen interface on board

Incremental encoder input (TTL) on board

Absolute encoder via CANopen, SSi, BiSS, Hiperface, EnDat

POSICON positioning control

External 24V power supply for control board

Synchronous motor operation (PMSM)

PLC logic function

Sizes 1 - 4 (0.25 - 7.5 kW):

Frequency inverter SK 500E with integrated mains unit / SK 505E with external 24V supply

SK 500E / SK 505E basic equipment:

Sensorless current vector control (ISD control)

Line filter Class C2, Class C1 up to 5 m

Brake management, electro-mechanical motor brakes

Brake chopper for braking resistor

RS 232 PC diagnostic interface

4 switchable parameter sets

All normal drive functions

Automatic flux optimisation (energy saving function).

Process controller / PID controller

Consistent parameter structure

Simple to operate

All common field bus systems

Factory setting for parameters for standard applications

Scalable display values

High quality regulation and short reaction times

- Q:What's the difference between a drive and a converter

- Inverter VVVF (variable voltage variable frequency) is simple, is in fact in China, foreign materials is generally called AC drives (AC driver (makes), obviously inverter is a kind of AC drives.

- Q:The failure of the step motor drive

- Here are some of the following questions: The problem of acceleration is that the speed of the machine is too fast. The current problem is that the current is too large or too small. Quality problems of actuators or motors Shenzhen pegatco CNC technology co., LTD. Is specialized in r&d step drive, controller, machine vision, solid state relay

- Q:What is the function of an electric motor

- Well, this is not very clear, but it should be a power source or something.

- Q:What are the advantages and disadvantages of the two approaches?

- Pneumatic driving: The disadvantage of this type system is that the power quality is small, so it is suitable for occasions where the beat is fast, the load is small and the precision is not high

- Q:Step forward motor single pulse/double pulse?

- Refers to when the motor three-phase three-phase motor stator winding Angle of 120 degrees (the difference between electric), pass into the three-phase alternating current (ac), will produce a rotating magnetic field, the rotating magnetic field cutting rotor winding, thus produce induced current in the rotor winding, rotor winding is closed path).

- Q:Why don't this step in the motor drive?

- You'll notice that the Settings of the drive - the segment is different. More segmentation, slower speed.

- Q:How the servo driver works

- The input signal of the servo driver is the switch signal, from the operating panel, the encoder. The output signal is the digital pulse to the motor, which makes the motor perform the relevant action. Maximum output torque setting Set the internal torque limit of the servo driver. Setting the value is the percentage of the rated torque, and at any time, the limit will be able to locate the range of the target within the range set position control. This parameter provides the position control mode the drive determine whether complete positioning basis, while the rest of the position deviation in the counter pulse number less than or equal to the parameters setting, drive think positioning has been completed, in place to ON switch signal, otherwise to OFF. When in position control mode, the output signal position location is complete, the setting of the deceleration time constant is said motor from 0 to 2000 r/min of acceleration time or from 0 to 2000 r/min deceleration time. Deceleration feature was arriving linear speed range set speed in the position control mode, if the servo motor at a faster rate than the set value, the speed to switch signal to ON, otherwise to OFF. In position control mode, no such parameter is used. It has nothing to do with the rotation.

- Q:The determination of the voltage and current of the step motor drive

- It's much better than low-voltage motors, such as 110V and 36V, for both torque and speed performance

- Q:How to set up the servo motor driver

- Servo drive is just according to your needs, set up in position, speed or torque control mode can be used, and then some unused terminal function can be shut off, the last is the gear ratio and the parameters optimization automatically

- Q:How is the single chip machine controlled

- Using a dedicated drive circuit like UN2003, such as the darlington array or L298N, you can also build your own H bridge.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

drive electronics SK 500E - Modular frequency inverter

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords