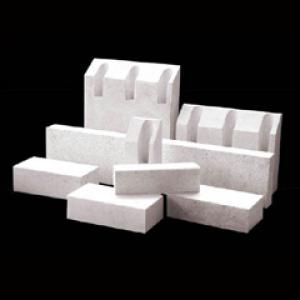

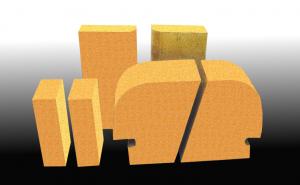

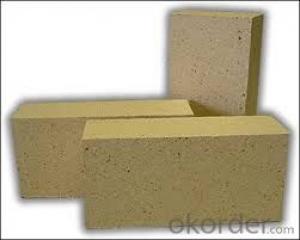

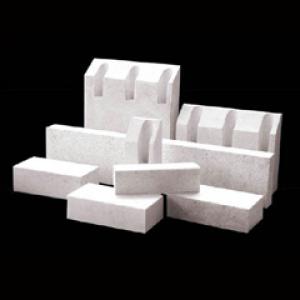

Corundum-Mullite Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

General Information

CMAX corundum-mullite bricks use the high-purity corundum as the main raw material, and are produced by advanced technology.

Feature

Low thermal conductivity

High strength

Good thermal shock resistance

Application

Industrial furnace lining

Glass furnace

- Q:What kind of refractory material is used in the hearth of reverberatory furnace?

- The use of temperature ceramic fiber long 950-1260 in general, there are many domestic manufacturers do not understand the deceive customers, often in accordance with the classification of temperature to the material sold to customers, such as zirconium ceramic fiber belongs to the 1400 type, but the long-term use temperature of 1260 degrees or less, impossible to maintain 1400 degrees to 1260 degrees, so the equipment in order to use ceramic fiber, high grade can only be used on polycrystalline fiber

- Q:2000 degree of high temperature materials, which belong to high temperature insulation materials?

- Magnesium compounds, ceramics, mica, corundum, silicon, graphite, titanium alloy, diamond, tungsten, silicon dioxide, silicon carbide, carbon, copper oxide, iron oxide, iron, manganese, lightweight mullite corundum brick, high aluminum brick lightweight clay brick, alumina hollow ball1) rock wool board: thermal conductivity 0.041-0.045, fire retardant, fire resistance, temperature absorption, insulation effect is poor.(2) glass wool: construction is simple, free cutting. Antibacterial, mildew proof, aging resistance, corrosion resistance, and guarantee the healthy environment. Low hygroscopicity and stable physical properties.

- Q:Mullite bricks in alumina alumina is what?

- With mullite as main crystalline phase of high alumina refractory products. Mullite bricks containing Al2O3 64%~75%, refractoriness >1790? C, normal temperature compressive strength 70~260MPa, softening the starting point for 1600~1700 degrees. The manufacturing method for casting and sintering process.

- Q:What are the high temperature insulation materials?

- Followed by a variety of lightweight bricks, alumina hollow ball, lightweight brick is relatively high temperature, about 1600 degrees. The others are low.Then there's the heavy brick. Heavy alumina brick, corundum mullite, can withstand 1750 degrees -1800 degrees. Mullite, cordierite lower lows.

- Q:What are the properties of corundum mullite?

- Heavy material has good compactness, high compressive strength, resistance to various corrosive gases, good thermal shock resistance, good thermal conductivity and wear resistance.

- Q:Corrosion mechanism of iron on refractory materials

- Iron oxide can not be used as refractory,

- Q:What material is heat insulated and not afraid of fire?

- Foam as a kind of important organic insulation materials, there are two kinds of polystyrene and polyurethane foam, which was published in 30s, the production in our country began in late 50s and 60s, which is characterized by the effect of thermal insulation performance, light weight, sound absorption properties, but the organic materials and brick wall with construction is difficult. Need the polystyrene foam plate is adhered in the walls with special binder and coupling agent, after a plurality of process, the construction is very complex. Moreover, foam plastic products have poor aging resistance, low service life, and waste materials can not degrade and cause white pollution.

- Q:Which is faster for heat transfer between corundum bricks and high alumina bricks?

- 43 3.65kg or so, the use of temperature 75, high aluminum in about 1520, 43 of brick 1430 or so, the color of 75 pan white, 43 of the Loess color. In short, the difference is great.

- Q:What material is good for refractory bricks?

- Is the main varieties of acidic silica brick, refractory brick. It is mainly used for coke oven building, also used in furnaces all kinds of glass, ceramic and carbon calciner, refractory brick arches and other load-bearing parts, is also used in high temperature bearing part of hot blast stove, but should not be used in thermal equipment below 600 DEG C and the temperature fluctuation in the.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Corundum-Mullite Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords