Concrete Reinforcing Welded Wire Mesh / Trench mesh / steel concrete mesh

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Reinforcing wire mesh is a welded wire fabric, prefabricated steel reinforcement material.

The fabric is used to provide tensile strength and crack control to structural concrete elements.

Specifications

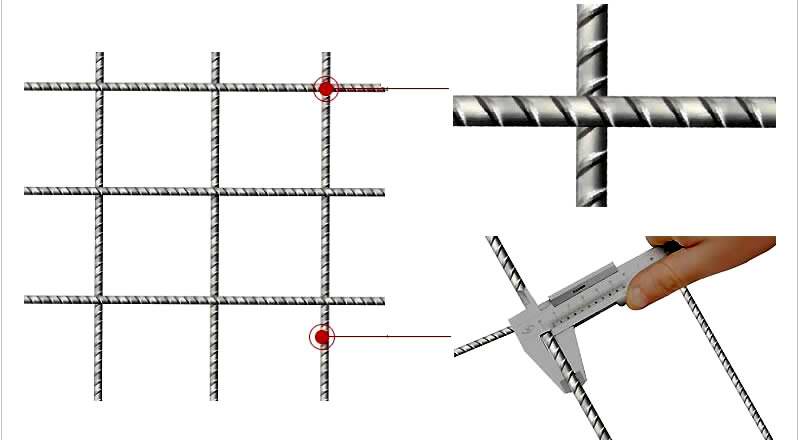

Wire diameter: 3mm to 12mm

Line wire spacing: min100 mm. larger line wire spacing in steps of 50 mm

Cross wire spacing: min 25mm. above programmable in increments of 0.1 mm

Wire mesh length: 500- 12000 mm

Wire mesh width: 500- 3300 mm

It's made of Deformed Steel Bars or Steel Rod.

Specification of Reinforcing Mesh

DIN488 GERMAN STANDARD (SIZE:2150MMX5000MM)

| Ref No. | Std Unit | Longitudinal Wires mm | Cross Wires mm | Pitch of wire | Mass Kg | Mass Kg/m2 |

| Q131 | Sheet | 5 | 5 | 150 @ 150 | 22.476 | 2.091 |

| Q188 | Sheet | 6 | 6 | 150 @ 150 | 32.401 | 3.014 |

| Q221 | Sheet | 6.5/5.0 | 6.5 | 150 @ 150 | 33.707 | 3.136 |

| Q295 | Sheet | 7.5/5.5 | 7.5 | 150 @ 150 | 44.245 | 4.116 |

| Q378 | Sheet | 8.5/6 | 8.5 | 150 @ 150 | 66.659 | 5.157 |

AS/NZS 4671:2001 Australia/New Zealand Standard (SIZE:6000X2400mm)

| Ref No. | Std Unit | Longitudinal Wires mm | Edge Wires mm | Cross Wires mm | Mass Kg |

| SL81 (F81) | Sheet | 7.6 @ 100 | 7.60 @ 100 | 7.60 @ 100 | 105 |

| SL102 (F102) | Sheet | 9.5 @ 200 | 6.75 @ 100 | 9.50 @ 200 | 80 |

| SL92 (F92) | Sheet | 8.6 @ 200 | 6 @ 100 | 8.60 @ 200 | 66 |

| SL82 (F82) | Sheet | 7.6 @ 200 | 5.37 @ 100 | 7.60 @ 200 | 52 |

| SL72 (F72) | Sheet | 6.75 @ 200 | 4.77 @ 100 | 6.75 @ 200 | 41 |

| SL62 (F62) | Sheet | 6 @ 200 | 4.77 @ 100 | 6 @ 200 | 33 |

| SL52 (F52) | Sheet | 4.77 @ 200 | 4.77 @ 100 | 4.77 @ 200 | 21 |

BS4483 BRITISH STANDARD

| Ref No. | Std Unit | Longitudinal Wires mm | Cross Wires mm | Pitch of wire | No. of sheet per ton | Mass Kg/m2 |

| A393 | Sheet | 10 | 10 | 200 @ 200 | 15 | 6.16 |

| A252 | Sheet | 8 | 8 | 200 @ 200 | 22 | 3.95 |

| A193 | Sheet | 7 | 7 | 200 @ 200 | 29 | 3.02 |

| A142 | Sheet | 6 | 6 | 200 @ 200 | 40 | 2.22 |

| A98 | Sheet | 5 | 5 | 200 @ 200 | 57 | 1.54 |

Application

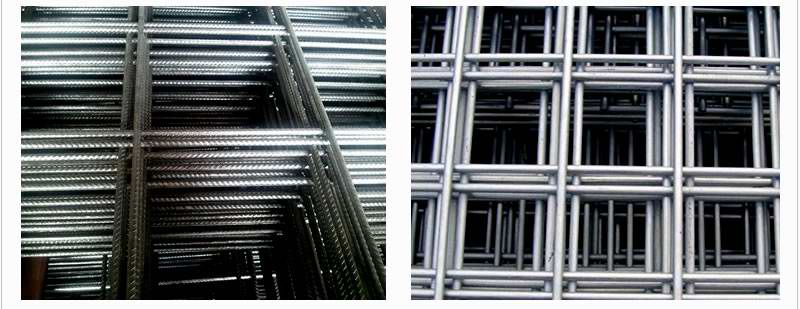

1. surface beds (concrete floor slabs on fill) and concrete roads

2. suspended floor slabs, concrete walls, culverts / drains and composite brick / concrete retaining walls

Packaging & Delivery

| Packaging Details: | 1. Around with Angle steel welded into a bundle 2. Use steel bar tied into a bundle 3. 50-100pcs into a bundle |

| Delivery Detail: | 7-15days after received the deposit. |

- Q: How is steel wire mesh used in reinforcement of power plants and energy facilities?

- Steel wire mesh is commonly used in the reinforcement of power plants and energy facilities to enhance the structural integrity of concrete structures. It is primarily used in applications such as concrete slabs, walls, and foundations to provide additional strength and prevent cracking. The steel wire mesh acts as a reinforcing material, distributing the load and increasing the overall durability and resistance to external forces. Additionally, it helps to control shrinkage and expansion of concrete, ensuring long-term stability and reducing maintenance costs in these critical infrastructure facilities.

- Q: Is steel wire mesh resistant to weathering?

- Yes, steel wire mesh is generally resistant to weathering. Due to its composition and protective coatings, it can withstand exposure to various weather conditions such as rain, sunlight, and temperature changes without significant deterioration. However, prolonged exposure to certain weather elements, such as corrosive agents or extreme humidity, may still cause some level of degradation over time.

- Q: Is steel wire mesh suitable for use in architectural sculptures?

- Yes, steel wire mesh is suitable for use in architectural sculptures. Steel wire mesh offers several advantages that make it a popular choice for creating sculptures in architectural projects. Firstly, steel wire mesh is highly versatile and can be easily manipulated into different shapes and forms. This allows architects and designers to create intricate and complex sculptures with ease. The flexibility of the material also allows for experimentation and creativity in the design process, resulting in unique and visually striking sculptures. Additionally, steel wire mesh is a durable and long-lasting material. It is resistant to corrosion and can withstand various weather conditions, making it ideal for outdoor sculptures. Its strength and stability also ensure that the sculptures remain intact and structurally sound over time. Moreover, steel wire mesh is lightweight, which is beneficial for architectural sculptures as it reduces the load and stress on the supporting structures. This enables the sculptures to be easily installed and transported, and it also provides the flexibility to create large-scale sculptures without compromising on stability. Furthermore, steel wire mesh is a cost-effective option for creating architectural sculptures. Compared to other materials such as bronze or stone, steel wire mesh is more affordable while still providing a visually appealing and contemporary look to the sculptures. Overall, steel wire mesh offers a range of advantages that make it suitable for use in architectural sculptures. Its versatility, durability, lightweight nature, and cost-effectiveness make it a popular choice among architects and designers looking to create unique and visually stunning sculptures in their projects.

- Q: How does steel wire mesh perform in electrical resistance?

- Steel wire mesh typically performs well in electrical resistance. Due to its high conductivity, steel wire mesh allows electrical current to flow easily through its structure. This makes it an efficient conductor of electricity, minimizing resistance and reducing the loss of electrical energy. Additionally, steel wire mesh is often used in applications where electrical grounding or shielding is required, as it can effectively dissipate electrical charges and provide protection against electromagnetic interference. However, it is important to note that the electrical resistance of steel wire mesh can be influenced by factors such as wire diameter, mesh size, and mesh configuration.

- Q: Can steel wire mesh be used for dewatering applications?

- Yes, steel wire mesh can be used for dewatering applications. It is commonly used as a filter medium to separate solids from liquids in various industries, such as mining, construction, and wastewater treatment. The mesh's open structure allows water to pass through while retaining solid particles, making it an effective tool for dewatering processes.

- Q: What are the different wire mesh shapes available in steel wire mesh?

- There are several different wire mesh shapes available in steel wire mesh, each serving a specific purpose and function. Some of the common wire mesh shapes include: 1. Square Mesh: This is the most basic and commonly used wire mesh shape, characterized by evenly spaced square openings. It is versatile and can be used for various applications such as fencing, filtration, and reinforcement. 2. Rectangular Mesh: Similar to square mesh, but with rectangular openings. It is often used in applications where a higher aspect ratio is required, such as in window screens and partitions. 3. Hexagonal Mesh: Also known as hex mesh or chicken wire, this shape features hexagonal openings. It is lightweight and flexible, making it ideal for applications like fencing, enclosures, and protection against small animals. 4. Diamond Mesh: This shape has diamond-shaped openings and is commonly used for security fencing, garden trellises, and decorative purposes. It provides a visually appealing pattern while maintaining structural integrity. 5. Welded Mesh: This type of wire mesh is created by welding the intersecting points of wires together, resulting in a strong and durable product. It can be found in various shapes, including square, rectangular, and diamond, and is commonly used in construction, concrete reinforcement, and industrial applications. 6. Expanded Mesh: In this shape, the wire mesh is formed by cutting and stretching a solid sheet of metal, creating diamond-shaped openings. Expanded metal mesh is lightweight, rigid, and provides excellent ventilation and visibility, making it suitable for applications such as walkways, ramps, and security screens. 7. Twilled Mesh: Twilled wire mesh features a diagonal pattern created by interlocking wires in a twill weave. This shape is commonly used for filtration, sieving, and separation applications where a finer mesh is required. These are just a few examples of the different wire mesh shapes available in steel wire mesh. Each shape has specific characteristics and applications, allowing users to choose the most suitable option based on their needs.

- Q: What are the benefits of using steel wire mesh in the marine industry?

- There are several benefits to using steel wire mesh in the marine industry. Firstly, steel wire mesh is known for its exceptional strength and durability. In the harsh marine environment, where structures are exposed to constant moisture, saltwater, and strong waves, a strong material like steel is essential. Steel wire mesh can withstand the corrosive effects of saltwater and remain intact for an extended period, ensuring the longevity of marine structures such as fences, barriers, and cages. Secondly, steel wire mesh offers excellent security and protection. It acts as a reliable barrier, preventing unauthorized access to restricted areas or protecting valuable equipment and resources. The tightly woven steel wires make it difficult for intruders to penetrate, ensuring the safety of marine assets and facilities. Additionally, steel wire mesh provides excellent visibility and ventilation. Its interwoven pattern allows for maximum airflow, preventing the accumulation of moisture and reducing the risk of corrosion. This feature is particularly crucial in the marine industry, where proper ventilation is essential to prevent the growth of mold, mildew, and other harmful organisms. Another advantage of using steel wire mesh is its versatility. It can be easily customized to suit various marine applications, including fish farming, marine construction, shipbuilding, and offshore drilling. Steel wire mesh can be tailored to specific sizes, shapes, and mesh patterns, making it adaptable to different requirements and specifications. Furthermore, steel wire mesh is a cost-effective solution in the long run. While the initial investment may be higher compared to other materials, the durability and low maintenance requirements of steel wire mesh make it a cost-efficient choice. Its resistance to corrosion minimizes the need for frequent replacements or repairs, ultimately saving money over time. In conclusion, the benefits of using steel wire mesh in the marine industry are its strength, durability, security, visibility, ventilation, versatility, and cost-effectiveness. These advantages make it an ideal material for a wide range of marine applications, ensuring the safety, longevity, and efficiency of marine structures and equipment.

- Q: What are the benefits of using steel wire mesh in the mining industry?

- One of the main benefits of using steel wire mesh in the mining industry is its high strength and durability. Steel wire mesh is able to withstand heavy loads and harsh conditions, making it ideal for use in mining operations. Additionally, steel wire mesh is resistant to corrosion, which is crucial in environments where moisture and chemicals are present. It also provides excellent visibility and ventilation, ensuring the safety and well-being of workers. Overall, steel wire mesh enhances operational efficiency, promotes safety, and reduces maintenance and replacement costs in the mining industry.

- Q: Can steel wire mesh be used for pet enclosures?

- Yes, steel wire mesh can be used for pet enclosures. It is a durable and strong material that can provide secure containment for pets while allowing visibility and ventilation. Additionally, steel wire mesh is resistant to chewing and scratching, making it suitable for various types of pets.

- Q: What are the weight and strength properties of steel wire mesh?

- Renowned for its exceptional strength and durability, steel wire mesh possesses certain weight and strength characteristics that depend on several factors, including the gauge of the wire, size of the mesh openings, and type of steel utilized. Regarding weight, steel wire mesh is relatively lightweight compared to solid steel materials of equivalent size and strength. This attribute facilitates easier handling and installation, particularly in large-scale applications like construction, fencing, and industrial environments. The weight of steel wire mesh can vary according to project-specific requirements, but it generally falls within a manageable range. Strength is a crucial attribute of steel wire mesh. Its tensile strength refers to its ability to endure stretching or pulling without breaking or deforming. Steel wire mesh displays high resilience and tensile strength, making it suitable for applications necessitating structural integrity and load-bearing capacities. The strength of steel wire mesh is determined by the thickness and quality of the wire employed. Thicker wires generally provide greater strength, while high-quality steel alloys enhance overall resilience and durability. This strength enables steel wire mesh to withstand heavy loads, resist impacts, and maintain its shape in diverse environmental conditions. Due to its excellent weight and strength properties, steel wire mesh is widely used in the construction, industrial, and agricultural sectors. It serves as a dependable material for reinforcing concrete structures, ensuring security and protection in fencing applications, and facilitating filtration and separation processes in industrial settings. In conclusion, steel wire mesh offers a balanced combination of weight and strength, making it a versatile and effective material in various applications. Its lightweight nature and exceptional strength make it a popular choice in industries where durability and reliability are of utmost importance.

Send your message to us

Concrete Reinforcing Welded Wire Mesh / Trench mesh / steel concrete mesh

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords