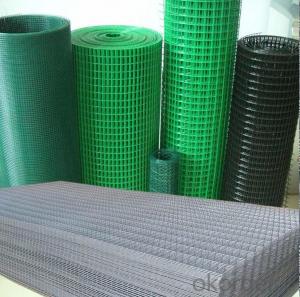

Heavy Duty Plastic Mesh Fencing

Heavy Duty Plastic Mesh Fencing Related Searches

Led Lamps For Ceiling Decorative Ceiling Plate For Light Fixture Ceiling Plate For Hanging Light Fiber Sheet For Roof Plastic Wall Coverings For Bathrooms Plastic Corner Protectors For Furniture Decorative Lights For Ceiling Plastic Netting For Gardens Ceiling Brackets For Lights Hanging Ceiling Chairs For BedroomsHot Searches

Steel Mesh Panels For Sale Price For Stainless Steel Scrap Scrap Price For Stainless Steel Cheap High Tea Sets For Sale Stainless Steel Tanks For Sale High Density Fiberboard For Sale Solar Hot Water Collectors For Sale Scaffolding For Sale In Uae Scaffolding For Sale In Ireland Scaffolding For Sale In Houston Type Of Inverter For Solar Price Of Shipping Containers For Sale Stock Price For Aluminum Used Solar Inverter For Sale Portable Led Signs For Sale Stone Hot Water Bottles For Sale Large Led Screens For Sale Used Aluminum Scaffolding For Sale 1/4 Aluminum Plate For Sale Heavy Duty Plastic Chairs For SaleHeavy Duty Plastic Mesh Fencing Supplier & Manufacturer from China

Okorder.com is a professional Heavy Duty Plastic Mesh Fencing supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Heavy Duty Plastic Mesh Fencing firm in China.Hot Products

FAQ

- Stainless steel wire offers a variety of wire mesh patterns, each designed for specific purposes. Let's explore some of the most common patterns: First, we have the Plain Weave, which is the simplest and most widely used pattern. It involves a straightforward over-and-under weaving technique that results in a uniform and tightly woven mesh. Next, we have the Twill Weave, known for its diagonal pattern. With this weave, each wire passes over two and under two wires, providing increased strength and durability. It is ideal for heavy-duty applications. Moving on to the Dutch Weave, this pattern uses thicker warp wires and finer weft wires. As a result, it creates a tightly woven mesh with a larger open area, enhancing filtration capabilities. It is commonly used in industries requiring precise filtration, like chemical and pharmaceutical sectors. The Reverse Dutch Weave is similar to the Dutch Weave, but with reversed warp and weft wires. This design offers a mesh with larger warp wires and finer weft wires, ensuring excellent strength and high filtration capabilities. Another interesting pattern is the Five-Heddle Weave, which boasts a unique crimped appearance created by five heddle frames. It offers a balanced combination of strength, flexibility, and filtration capabilities. Lastly, we have the Welded Wire Mesh, where the wires are spot welded at their intersections. This creates a rigid and strong mesh structure, making it commonly used in industrial applications like fencing, construction, and reinforcement. These are just a few examples of the various wire mesh patterns available for stainless steel wire. Each pattern has its own distinct characteristics and advantages, so it is crucial to select the right pattern based on the specific requirements of the application.

- There are several different types of stainless steel wire fasteners available in the market. Some of the most common types include: 1. Stainless steel screws: These are threaded fasteners used to join two or more objects together. They come in various lengths, diameters, and head styles to suit different applications. 2. Stainless steel bolts: Similar to screws, bolts are also threaded fasteners, but they typically have a larger diameter and require a nut to secure the joint. They are commonly used in heavy-duty applications. 3. Stainless steel nuts: Nuts are used in conjunction with bolts to secure the joint. They come in different shapes and sizes, including hexagonal, square, and winged nuts. 4. Stainless steel washers: Washers are flat, thin metal discs used to distribute the load evenly and prevent damage to the surface of the material being fastened. They are available in various sizes and shapes, such as flat washers, lock washers, and fender washers. 5. Stainless steel rivets: Rivets are permanent fasteners that are typically used to join two or more materials together by deforming the end of the rivet after insertion. They are commonly used in industries such as automotive, aerospace, and construction. 6. Stainless steel clips and clamps: Clips and clamps are used to secure or hold objects in place. They are available in various designs, such as spring clips, hose clamps, and pipe clamps. 7. Stainless steel nails: Nails are pointed fasteners used to secure materials together. They are commonly used in woodworking and construction applications. 8. Stainless steel pins: Pins are cylindrical fasteners used to hold components in place or to align two or more parts together. They come in various shapes, such as dowel pins, cotter pins, and hitch pins. 9. Stainless steel hooks: Hooks are curved fasteners used to hang or suspend objects. They are commonly used in applications such as hanging plants, tools, or decorative items. It's important to note that these are just a few examples of the different types of stainless steel wire fasteners available. The choice of fastener will depend on factors such as the application, load requirements, and environmental conditions.

- Using stainless steel wire for papermaking is not possible. Papermaking necessitates the utilization of particular materials like mesh screens or wire cloth, typically composed of nylon, polyester, or brass. Stainless steel wire is unsuitable for papermaking as it has the potential to harm the delicate paper fibers and may cause complications in the papermaking process.

- Yes, stainless steel wire can be used for wire rope sling assemblies. Stainless steel wire offers excellent corrosion resistance, making it suitable for applications where the sling may be exposed to harsh environments or chemicals. Additionally, stainless steel wire has high tensile strength and durability, allowing it to withstand heavy loads and repeated use. However, it is important to ensure that the stainless steel wire used in the wire rope sling assemblies meets the required specifications and standards for the intended application.

- What are the advantages and disadvantages of wire drawing stainless steel?

- Drawing process will to some extent lose the thickness of stainless steel plate, usually at 0.1~0.2mm. In addition, because the human body, especially the palm has a relatively strong oil and sweat secretion, stainless steel wire drawing board often hand touch will leave a more obvious fingerprints, regular scrub.The drawing is divided into: stainless steel, oil mill, dry grinding mill, drawing drawing drawing, the drawing effect is the most ideal oil mill, and the appearance is satisfactory!

- Musical instrument strings can be crafted from stainless steel wire, which provides several advantages. To begin with, stainless steel is renowned for its durability and ability to resist corrosion, making it an optimal material for strings that are constantly exposed to moisture, sweat, and other environmental elements. Consequently, stainless steel strings have a lengthier lifespan and can endure regular use without experiencing tone loss or breakage. Moreover, stainless steel wire produces a vibrant and sharp tone that is sought after by many musicians. The high tensile strength of stainless steel enables precise intonation and resonance, rendering it suitable for a variety of instruments including guitars, mandolins, banjos, and more. Additionally, stainless steel strings enhance sustain and projection, thereby amplifying the overall sound quality of the instrument. Nevertheless, it is important to acknowledge that the selection of string material relies on personal preference and desired sound characteristics. Some musicians may favor the warmth and mellowness provided by other materials such as nickel or bronze, while others may choose the bright and focused sound of stainless steel. Ultimately, the decision regarding string material should be based on the specific instrument, playing style, and desired sound outcome.

- Compared to other materials, stainless steel wire typically falls within the mid to high range in terms of cost. While it may be more expensive than materials like aluminum or carbon steel, stainless steel wire offers unique benefits that justify its higher price. Stainless steel is renowned for its exceptional corrosion resistance, durability, and strength, which make it a preferred choice in industries such as construction, automotive, and aerospace. Moreover, stainless steel wire exhibits high resistance against heat, chemicals, and wear, ensuring long-term usage and reduced maintenance expenses. Hence, despite the higher upfront cost, stainless steel wire proves to be a valuable investment in various applications due to its long-term value and performance.

- Yes, stainless steel wire can be used for filtration applications. Stainless steel is a durable and corrosion-resistant material, making it suitable for various filtration processes. It is often used in industrial settings to filter liquids, gases, or particles. Stainless steel wire can be woven into different mesh sizes and shapes to achieve the desired filtration efficiency. Additionally, the wire can be coated or treated with various substances to enhance its filtration properties, such as improving resistance to high temperatures or chemical reactions. Overall, stainless steel wire is a versatile material that can effectively meet the filtration needs of different industries.