China best selling VFD Frequency Drive 3 phase 380V 55KW

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.220V Single Phase Variable Frequency Drive 2.2KW

2.Advanced control technology

3.Easy to operate

220V Single Phase Variable Frequency Drive 2.2KW

General

CNBM frequency inverter is a high-quality, multi-function,

low-noise variable frequency drive which is designed, developed and manufactured according to international standards.

It can meet different needs of industrial conditions.

The inverter applies advanced control technology of space voltage vector PWM, with functions of constant voltage control, power-off restart, dead zone compensation, automatic torque compensation, online modification parameter, high-speed impulse input, simple PLC and traverse.

Product Name:CMAX-VCG15/P18.5T3 ~ CMAX-VCG18.5/P22T3

Application

Textile: coarse spinner, spinning frame, wrap-knitting machine, loom, knitting machine, silk-spinning machine, etc.

Plastic: extruder, hauling machine, decorating machine, etc.

Pharmacy: mixer, roaster, etc.

Woodworking: engraving machine, sander, veneer peeling lathe, etc.

Papermaking: single type papermaking machine, etc.

Machine tool: non-core grinding machine, optical lens grinding machine, cutting mill, etc.

Printing: cloth-washing machine, dye vat, etc.

Cement: feeder, air blower, rotary furnace, mixer, crusher, etc

Fan and pump: kinds of fans, blowers and pumps

Specification

Item | Specification | |

Input | Input voltage | 220/380V±15% |

Input frequency | 47~63Hz | |

Output | Output voltage | 0~input voltage |

Output frequency | 0~600Hz | |

Peripheral interface characteristics | Programmable digital input | 4 switch input, 1 high-speed impulse input |

Programmable analog input | AI1: 0~10V input AI2: 0~10V input or 0~20mA input, | |

Programmable open collector output | 2 Output (3.7kW and above: 1 Open collector output) | |

Relay Output | 1 Output (3.7kW and above: 2 Relay output) | |

Analog output | 2 Output, one is 0~10V, another is 0~20mA or 0~10V | |

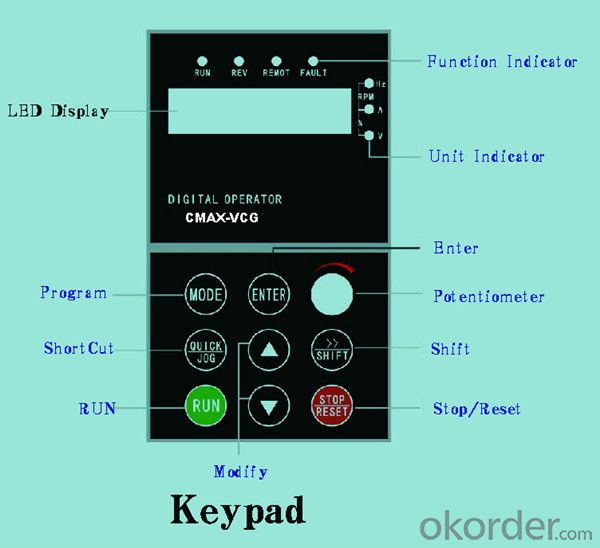

Keypad | Display:5-digit 8-section LED (Red), 2 indicators; parameter setting: 8 keys (including multi-function hot key ), 1 potentiometer | |

Technical performance characteristics | Control mode | All digital space voltage vector SVPWM algorism |

Overload capacity | G purpose: 150% rated current 60s P purpose: 120% rated current 60s | |

Speed ratio | 1: 100 | |

Carrier frequency | 1.0~10.0kHz | |

Torque compensation | Linear, multi-point, 1.3th power, 1.7th power, 2.0th power reduced torque; Compensation voltage range: automatic compensation and manual compensation 0.1~10% | |

Automatic voltage adjustment | It can automatically maintain output voltage constant when grid voltage fluctuates. | |

Automatic current adjustment | When the current is over current limit, under clocking automatically limits output current. | |

Function characteristics | Frequency setting mode | Keypad digital analog input, keypad potentiometer, impulse frequency, communication, multi-step speed and simple PLC, PID setting and so on, switch-over of setting modes. |

Simple PLC, multi-step speed control | 16-step speed control | |

Special function | Traverse control, length control, time control | |

QUICK/JOG key | User-defined multi-function hot key | |

Protection function | Over-current, Over voltage, under-voltage, over-heat, phase failure, over-load and motor over-load | |

Working condition | Installation site | Indoor, altitude of less than 1km, dust free, non-corrosive gases, no direct sunlight |

Application environment | -10°C~+40°C, 20~90%RH (no dew) | |

Vibration | Less than 0.5g | |

Storage temperature | -25°C~+65°C | |

Installation type | Wall-mounted type, floor cabinet type | |

Cooling mode | Air-forced cooling | |

- Q:How does the frequency converter fit the brake unit and the brake resistor?!

- Calculate the motor energy, as to choose how much resistance, another factor is the braking time. If a short time braking, requires relatively large resistance, on the other hand, can choose small resistance. This depends on the mechanical requirements.

- Q:What's the frequency converter for? What does it look like?

- The inverter is mainly used in industrial equipment, such as power plants, water plants, water supply equipment, large pumping station, it is basically a cuboid, a digital display control panel; and in the English show types into the universal type, fan pump type, vector control, different types should be used in different working conditions, voltage grade from 220V-10 million volts.

- Q:Why does harmonic generator produce harmonic? What's his working principle?

- The harmonic generation mechanism of frequency converter is because of the non-linearity of frequency converter, including two parts: rectifier and inverter. For a simple example, the streams we see are, if there is no wind, and the bottom is flat, then there will be no waves, no ripples. This is because the water flows through the region is linear. Because of the fact that the wind and the water are not flat enough, these nonlinear conditions lead to waves and ripples.

- Q:The functions of frequency converter and UPS are similar, especially the power frequency UPS?

- The inverter is actually an inverter. It is the first AC into DC. And then use the electronic element to switch DC power into AC inverter. In general. Large power SCR. And an adjustable frequency. The device can be adjusted in a certain range of frequency is used to control the motor speed. The speed can be adjusted. In a certain range. The inverter is widely used in AC motor speedThe UPS power supply is also called an uninterruptible power supply. An inverter with an adjustable frequency. Battery powered. For short time power supply of computer and other equipment in case of power failure. Prevents sudden power loss and file loss.

- Q:Frequency converter OC alarm, what's the matter?

- A "Taiwan" type N2 power type, power jump UL or UU fault, refused operation. Check the three-phase current transformer signal, the three signal is seriously deviation, or at least it has broken two. But check the specification of the manual code, there is no such twoKind of fault code, guess this code is factory repair personnel can crack password, insufficient for outside humanitarian. Does it also indirectly indicate the OC fault? Only to be repaired in order to have an answer.

- Q:What's the use of switching frequency of converter?

- The chopper device also has switching life, the higher the switching frequency, the shorter the life of the inverter, and will reduce the inverter output current and power. The smaller the chopping frequency, the higher harmonic content and the more serious harmonic pollution.

- Q:What is the function of a frequency converter on an electric motor?

- Frequency converter integrates high voltage, high power transistor technology and electronic control technology, and has been widely used. The role of frequency converter is to change the frequency and amplitude of AC motor power supply, thus changing the period of its moving magnetic field, to achieve the purpose of smooth control of motor speed. The inverter speed control, makes the complex simple, most of the original work can only be done by a DC motor instead of frequency converter + AC squirrel cage induction motor, reduce the volume, reduce the maintenance rate, to a new stage of development of the transmission technology

- Q:It was when processing a workpiece, processing spindle stops suddenly (other are normal) a check is, I jump out of the inverter, I can click on a processing, and then processing not long after they happen, (do not open the machine spindle machining will also be the case)

- It should be a frequency converter. Right now, look at the frequency converter output frequency settings, tune, and suggest the next election wide output frequency converter, or simply PLC

- Q:Why does the frequency converter cause interference?

- Method for solving interference caused by frequency converter:Adopt software anti-interference measures: specifically, the carrier frequency of the inverter is lowered through the man-machine interface of the inverter, and the value is reduced to an appropriate range. If this approach does not work, then only the following hardware anti-interference measures can be taken.Carry out the correct grounding: through the field investigation, we can see that the site of the ground is not ideal. The correct grounding can not only effectively suppress external interference, but also reduce the interference of the equipment itself to the outside. It is the most effective measure to solve the interference of frequency converter. Specifically, do the following two points:

- Q:How do you understand the ramp up (descent) time of the inverter? Thank you!

- The reverse is the drop time, or the 0 speed. Water pumps and fan motors are basically not required to change. If it is an emergency stop, it is usually 3 seconds (depending on the frequency converter and process requirements).

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

China best selling VFD Frequency Drive 3 phase 380V 55KW

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords