Ceramic Fiber Loose Wool for Heat Insulation for Kiln Door and Roof

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 300000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

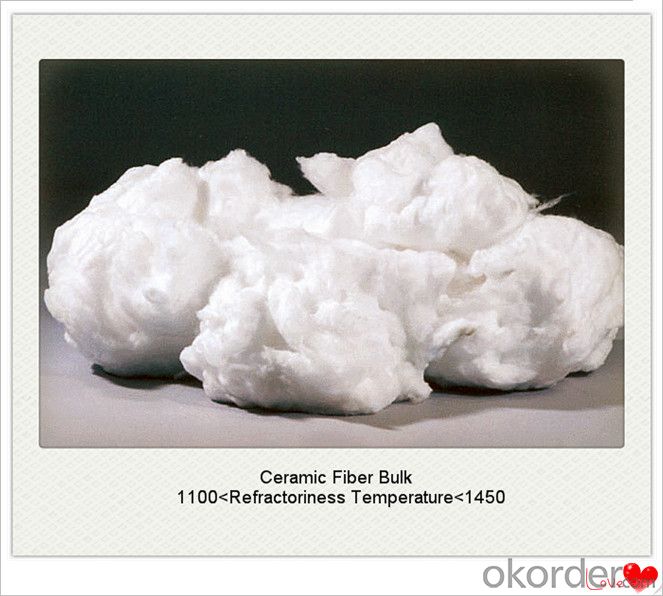

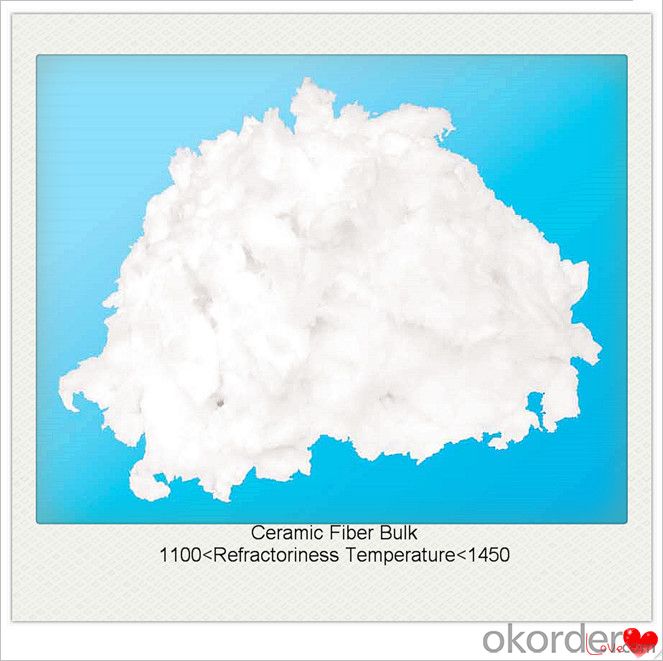

Ceramic Fiber Bulk for Heat Insulation for Kiln Door and Roof

Description for Ceramic Fiber Cotton Bulk/Loose Wool

Ceramic fiber bulk is made by chopping the ceramic fiber spun bulk, it is an ideal material for making ceramic fiber board and vacuum formed ceramic fiber shapes.

Features for Ceramic Fiber Cotton Bulk/Loose Wool

1.Low heat capacity and low thermal conductivity;

2.Excellent chemical stability;

3.Excellent thermal stability, resistance to pulverization at high temperature;

4.With no binders or corrosive substances;

5.Excellent sound absorption

Application for Ceramic Fiber Cotton Bulk/Loose Wool

1.Raw material for fiber blanket, board products;

2.Raw material for fiber textile products;

3.Fillings for wall lining gap in high temperature furnace, heating device;

4.Raw material wet processed products;

5.Fiber spraying;

6.Castables;

7.Raw material for coatings;

8.Insulation fillings for corner and complex space.

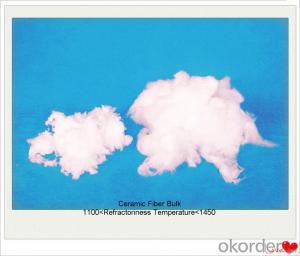

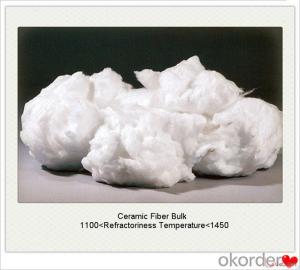

Major Images for Ceramic Fiber Cotton Wool Bulk/Loose Wool

Packaging and Delivery for Ceramic Fiber Cotton Bulk/Loose Wool

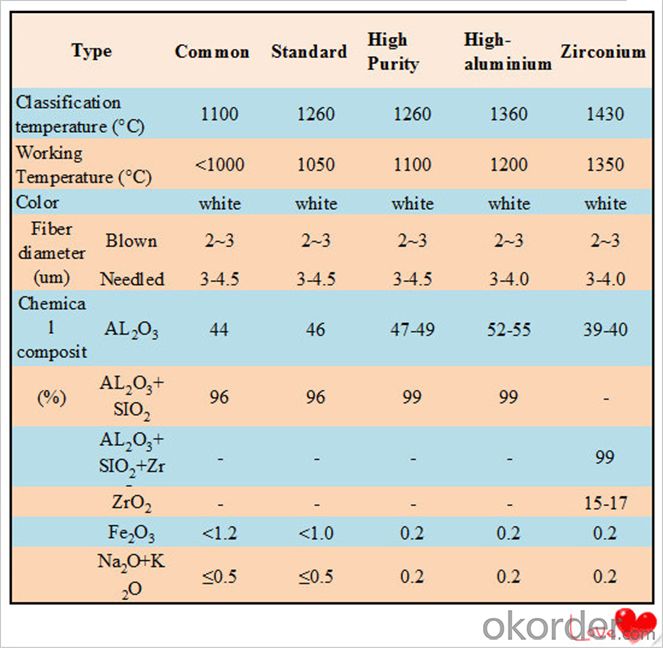

Technical Data and Specification for Ceramic Fiber Cotton Wool Bulk

Why Us

1. Strong professional:

We are state-owned company, ranking 267th/Fortune Global 500. We have clients from over 160 countries and wholly-owned overseas subsidiaries and branches in 10 countries.

Our company has thirty years producing experience in refractory product. Our manager will supervise on a various refractory’ s production materials, process control, quality supervision and package delivery,and ensure the products are 100% qualified.

2. Annual supply:

Our company has passed ISO9001 quality management system certification and SGS certification. And the annual supply of shaped and unshaped refractory product is 28,800-35,000 tons..

3. Annual exports:

Now we have gained a global sales network reaching Taiwan, Russia, Mongolia, South Korea, Vietnam, Pakistan, Bulgaria, Finland, Greece,Spain, Congo, Angola, South Africa, and Maldives,Jordan and so on.

4. Production equipment:

Production and testing equipments are new, complete and automated or semi- automated. Such modern facilities and equipments have provided the fine technical guarantee for the production and testing.

5. Testing equipment;

Our company’s testing equipments as follows:

High Temperature RUL Tester

Bulk Density Tester

The Pressure Tester

Refractoriness Tester

FAQ for Ceramic Fiber Bulk

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories, at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time, seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Which payment terms can you accept?

A:T/T,L/C are available for us.

Q5:After an order is confirmed, when to deliver?

A:15-25days after deposit.

Q6:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q7:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q8:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q9:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q10:What is the service life of your products?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

- Q:What are the main differences between an ordinary furnace and a ceramic fiber furnace?

- The main difference between ordinary furnace and ceramic fiber furnace:Refractory, heat insulation: ceramic fiber furnace low thermal conductivity, low thermal conductivity, is a better thermal insulation materials, the use of temperature within one thousand and three hundred Baidu. The heat conductivity of common furnace is higher and the heat loss is great

- Q:What is the density of ceramic fiber modules? The best insulation effect

- Ceramic fiber module density is only a standard in the world, is 220Kg/m fand, but in the actual application, according to the heat treatment furnace, furnace temperature, combustion medium, temperature rise requirement of ceramic fiber module density in 200-240Kg/m fand, ceramic fiber blanket, because the processing of ceramic fiber module uses double roller today advanced technology and technology of silk, fiber length of the ceramic fiber blanket which produced in 80-130 mm, so the maximum density of the ceramic fiber module is more than the density, 240Kg/m fand, a large amount of fiber fracture, the fracture rate is as high as 48%. So after the actual verification at home and abroad of tens of thousands of industrial furnaces, the best density of ceramic fiber module is fand 220Kg/m.

- Q:What is the diameter of the ceramic fiber? How to mix?

- Fiber diameter: rejection fiber more coarse, rejection fiber generally 3.0-5.0 - m, spinneret fiber is generally 2.0-3.0 - m;

- Q:Ceramic fiber material fire shutter door how many square?

- Now there are two kinds of rolling to use ceramic fiber: a called inorganic super fire shutter (commonly known as the double track curtain), the curtain surface is glass fiber cloth + ceramic fiber cloth + ceramic fiber blanket + aluminum foil cloth, one is WFJ (glass fiber cloth + ceramic fiber cloth + glass fiber cloth).

- Q:The difference between the ceramic fiber blanket and rock cotton blanket

- The heat capacity (heat storage capacity) of ceramic fiber lining is low: the heat capacity of ceramic fiber is only about l/10 of light heat resistant lining and light castable lining, and the heat capacity of lining material is proportional to the weight of lining. Low heat capacity means the furnace in the reciprocating operation absorb less heat and heating speed, greatly reducing the operational control of the temperature in energy consumption, especially for heating furnace and furnace, furnace shutdown has obvious energy saving effect.

- Q:Is the ceramic fiber cloth poisonous?

- With aluminum, zinc and other non-ferrous molten metal erosion capacity. Excellent high temperature strength. The bottom heat conductivity makes the product have good heat insulation performance. Excellent electrical insulation performance. Non-toxic, harmless, no adverse effects on the environment, excellent tensile properties.

- Q:Aluminum silicate needle carpet and ceramic fiber insulation performance of the good

- Aluminosilicate ceramic fiber has two different production processes, respectively, the rejection process and the blowing process. The carpet produced by the spinning process has long fiber length, high tensile strength and wide range of use. The blanket produced by blowing process is short in length and easy to break, and the scope of application is relatively narrow.

- Q:Is aluminum silicate fiber poisonous?

- Hello, silicate in the stomach and stomach acid reaction, forming insoluble silicic acid. There should be no toxicity.

- Q:Glass fiber cotton, aluminum silicate cotton, rock wool, what's the difference between these three?

- Rock wool: is a kind of insulation materials, widely used in exterior wall insulation, because rock wool dust carcinogenicity, the state has banned the use of industry.

- Q:What is the difference between the ceramic fiber cloth and the high silicon oxygen cloth?

- Ceramic fiber is a short fiber that needs to be reinforced and toughened by other objects. It is generally toughened by glass fiber and stainless steel wire. The high silicon oxygen is long fiber, no need to toughen by other objects. The short-time high silica resistance to high temperature, Suzhou Dexin ceramic high silica cloth of silica content is greater than or equal to 96% temperature up to 1700 DEG C.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ceramic Fiber Loose Wool for Heat Insulation for Kiln Door and Roof

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 300000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords