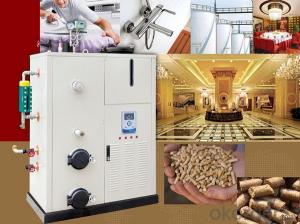

Biomass Pellet Hot Blast Stove Commercial&Risidental

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 unit

- Supply Capability:

- 10000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.10000~30000Kcal

2.920x450x890mm

3.Can be customized

4.Biomass Pellet Fuel

5.Apply to dry and heat for greenhouse,industry

Introduction

The released CO2 gas when boiler combusting can not only get rid of excess moisture inside the greenhouse, but also help plants for photosynthesis.

Key Features

Energy saving: in the first minute after power on, complete the process from ignition to combustion, heating rapidly.

Intelligent effort: microcomputer control system to control the automatic ignition, feeding and thermostat, just 1-2 times a day to refuel, almost no need of manual work.

Friendly to environment: completely full fuel combustion can achieve the effect of smokeless, dust-free and odorless.

Particularly apply to dry and heat for greenhouses, industries, enterprises.

Application Range

Widely used to heating in greenhouses, heating projects, industrial plants and civil buildings; preparation and drying for chemical and pharmaceutical industries; drying for sand and sand core in foundry industries, drying for abrasives tools, gauze and grinding wheel in abrasive industries; Baking paint and powder curing for automobile, motorcycle, container, appliance, tinplate printing and other industrial products in coating industries; heat setting, hot melts dyeing, baking, drying for wood.

Specification

| Project | Unit | GS-0.035 | GS-0.12 | GS-0.24 | GS-0.54 |

| Rated heating value | Kcal | 1-3×104 | 10×104 | 20×104 | 45×104 |

| Working pressure | MPa | ordinary pressure | |||

| Thermal efficiency | % | 85 | 91 | 91 | 92 |

| Induced draft fan | KW | / | 0.75 | 1.1 | 3 |

| Circulating fan | KW | 0.3 | 2.2 | 2 | 7.5 |

| Flue duct hole diameter | mm | Φ108 | Φ165 | Φ165 | Φ220 |

| Fir outlet | mm | 465x410 | 300x300 | 300x300 | 400x400 |

| Fir inlet | mm | 465x410 | dia300 | 300x240 | dia350 |

| Boiler weight | kg | 90 | 650 | 910 | 2080 |

| Fuel consumption rate | kg/h | 2.2-5.3 | 13.9 | 39.9 | 88.9 |

| Heating area | m2 | 100-300 | 700-920 | 1400-1800 | 2700-4500 |

| Air velocity | m³/h | 230 | 1264 | 2700 | 3166 |

| Boiler size: length | mm | 920 | 2075 | 2395 | 3130 |

| Boiler size: width | mm | 450 | 680 | 930 | 1000 |

| Boiler size: height | mm | 890 | 1200 | 1850 | 1720 |

| Silo size: length x width x height | cm | Silo internal | 50x40x60 | 50x40x60 | 60x60x80 |

- Q:I want to say is methane, natural gas, liquefied petroleum gas to methane content to distinguish, what are the basis and norms or standards to illustrate the percentage, they contain methane gas, biogas, what are the content of methane in the liquefied petroleum gas, what basis and norms or standards.

- Natural gas and liquefied petroleum gas to conventional fossil energy, gas and town gas design handbook design rules for what is natural gas and liquefied petroleum gas has a clear definition, conventional gas component content can refer to your regular teacher for the "gas". The main components of natural gas is methane, methane the content above 90%

- Q:How to extract diesel

- Eat 2 ~ 3 particles that cause dizziness, vomiting, abdominal pain, diarrhea, eat more symptoms, have difficulty breathing, skin cyanosis, circulatory failure, and have less urine, hematuria and obvious hemolysis phenomenon, and finally collapse death]. The ethanol extract of 22.2g/kg bark was injected into the abdominal cavity of mice, and the activity decreased, jitter, quiet, eyes closed, and died. Chemical composition: seeds contain toxic protein Jatropha toxin, fatty oil. In addition to containing flavonoids Vitexin and isovitexin and apigenin.

- Q:Biogas can be used for heating it?

- At present, countries around the world have begun to use biogas as fuel and lighting. The use of biogas instead of gasoline, diesel, the effect of the machine is also very good. It has many advantages as rural energy. For example, the construction of an average l of 1.5 square meters of the fermentation tank, firewood and lighting problems can be basically solved throughout the year; people and livestock manure and crop straw and weeds, through fermentation, which generates methane, also can be used as a fertilizer, but also because of a high degree of maturity to make fertilizer higher manure biogas fermentation, the vast majority of parasite eggs were killed, can improve the sanitary conditions in rural areas, reduce the spread of diseases. Now, the application of biogas is spreading in many countries, and the development and utilization of biogas energy has achieved good results.

- Q:What is the filling of the biogas tank?

- Problems should be paid attention to in the process of biogas fermentationThe essence of biogas fermentation is the process of microbial life, and the life process of microorganism is influenced and restricted by various factors. Therefore, the following points must be paid attention to in the process of operation

- Q:Why biodiesel is a typical "green energy", which is of great significance to the development of biodiesel industry...

- Biodiesel is a typical "green energy", vigorously develop bio diesel for sustainable economic development

- Q:What is the calorific value of biodiesel

- Biodiesel:Biodiesel, also known as biodiesel, is an environmentally friendly biofuel made from unprocessed or used vegetable oils and animal fats.

- Q:Development prospect of urban biogas

- There are three basic processes in an anaerobic digester:The first phase of the hydrolysis of insoluble organic compounds and polymers, converted into soluble organic matter by enzymatic method.The second stage will be converted into products such as carbohydrates, proteins, fats, alcohols and other organic acids fermentation.In the third stage, methane is produced by fermentation of organic acids.

- Q:When the methane in the methane tank is not enough, there is no use of water in the pond

- The fermentation of biogas fermentation materials suitable is the material basis to produce biogas digesters, in order to ensure the start and fermentation fermentation of raw materials sufficient and stable, in before feeding, fermentation of raw materials need to choose the suitable organic nutrition of cattle and pig manure, sheep manure and so do the start. These raw materials are fine particles, containing a lot of low molecular weight compounds, carbon and nitrogen ratio is less than 25:1, which is suitable for the fermentation of carbon and nitrogen ratio, after entering the pool to start fast, good gas production. Do not start with chicken manure, manure, these raw materials in the case of less methane bacteria, the material is easy to acidification, fermentation can not be normal. The fermentation concentration of 3, the first loading the biogas digesters to fit the first feeding amount should be 80% if the volume of the pool, because of the temporary lack of raw materials, one-time feeding can not meet the requirements of feeding quantity (most household biogas digester will not have such ample raw materials), and more than the water inlet and outlet 15 cm, closed fermentation fermentation. The first feeding concentration using 6%--10%, if the proportion of raw materials and water in the methane tank is difficult to estimate, would rather thin, not too strong, otherwise easy acidification.

- Q:What is diesel oil refined

- . Its chemical and physical properties are located between gasoline and heavy oil with a boiling point of 170 DEG C to about 390 DEG C with a specific gravity of 0.82~0.845kg/l. Obtained from crude oil, shale oil, etc. by direct distillation or cracking. According to the different properties of crude oil, paraffin based diesel oil, naphthenic base diesel oil, naphthenic aromatic diesel oil, etc..

- Q:I would like to ask how biogas production

- 2.2.1 fixed arch cover hydraulic digesters?The fixed arch cover hydraulic tank has a cylindrical shape (see Figure 2.1), a sphere (see Figure 2.2) and an ellipsoid (see Figure 2.3). The gas chamber on the upper part of the pool body is completely closed, and with the constant production of methane, the methane pressure increases correspondingly. The continuously increasing air pressure forces a part of the material liquid in the methane tank into the water pressure chamber communicated with the pool body, so that the liquid level in the water pressure chamber is increased. As a result, the water level in the water tank with the liquid level in the body will produce a water level difference, the water level difference is called "water pressure" (that is, the U tube methane pressure meter display value). When the utility model is used for gas, the methane switch is opened, and the methane is discharged under the water pressure; when the methane is reduced, the material liquid between the water pressure returns to the pool body, and the water level difference is continuously decreased, and the methane pressure is correspondingly reduced. The utility model uses a part of the material liquid to move back and forth, which causes the water pressure to change repeatedly to store and discharge methane.There are generally two kinds of biogas digesters, one is made of ordinary cement, and the other is made of glass fiber reinforced plastic, glass fiber is divided into ordinary type and patent type

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Biomass Pellet Hot Blast Stove Commercial&Risidental

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 unit

- Supply Capability:

- 10000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords