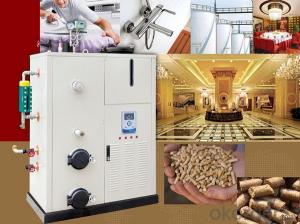

Multifunctional Biomass Pellet Cooking Stove

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 unit

- Supply Capability:

- 10000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.8~15KW Cooking Stove

2.1025x550x715mm

3.Can be customized

4.Biomass Pellet Fuel

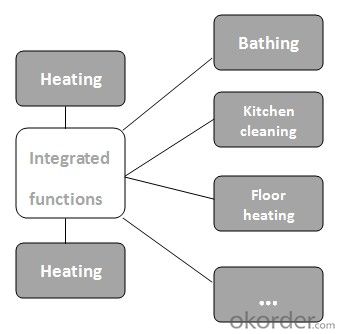

5.Multi Functions In a machine

Introduction

Multifunctional biomass cooking stove is a well-developed high-end product by us. This series produced in order to response to national policy, namely encouraging clean, efficient development and utilization of biomass, turning “waste” into wealth. This product can replace traditional oil / gas stove and backward household mud stove which being used in hotels and other industries. It is a multi-purpose stove, can be used for cooking, boiling, heating, etc. Wok, steamer, pressure cooker, kettle and other kitchen utensils can be put on the top of the stove, to meet different needs.

Key Features

Strong thermal power: stove flame temperature can reach to 1,000 degrees when sufficient burning.

Clean and green: Burning ashes are all access to the hopper, no smoke and dust in operating room.

Beautiful appearance: product’s outer packing boards are all use molding, soft colors, beautiful appearance.

Fuel advantage: suitable for straw, wood and other biomass briquette, low operating cost, save 40% than gas stove, 50% than electric stove province, 60% than oil furnace

Application Range

Widely used in hotels, snacks, canteens, factories, rural families, bath, warming, floor heating, etc.

Specification

| Project | Unit | GS-1-M |

| Design out of water | kg/h | 200~300 |

| Available fuel | / | Biomass pellet fuel |

| Overall size | mm | 1025x550x715 |

| Design power | KW | 8~15 |

| Reference heating area | m2 | 60~70 |

| Fuel consumption rate | kg/h | 1.5~3 |

| Weight | kg | 115 |

Note:

1.The data is for reference only, technical specifications may be subject to change without prior notice.

2. Our products can be customized. If any other parameters are needed, please contact me.

FAQ

Q:What's my consideration when i choose a gas stove?

A: -The style and size of your kitchen.

-The food or cooking style you prefer.

Q:Can i be a distributor of CNBM?

A: Of course you can.

Q:What are the benefits of being your gas stove distributor?

A: - Marketing protection.

- Priority of launching new design.

- Point to point technical supports and after sales services.

Q: How can i become a distributor of CNBM stoves?

A: Contact us immediately for further details by sending us an inquiry.

- Q:Production of biodiesel companies need to do what documents?

- Production of bio diesel companies need to do business card, tax card, environmental impact assessment certificate, project permits, feasibility study report card, security certificate, fire certificate, etc.

- Q:Biodiesel need to apply for a production license

- A business license by the provincial economic and trade administrative departments, autonomous regions and municipalities directly under the central government or its entrusted production safety supervision and management departments (hereinafter referred to as the provincial approval, issued by the issuing authority); B license by the Municipal People's Government districts responsible for the comprehensive work safety supervision and management of hazardous chemicals (hereinafter referred to as the Department the municipal approval, issued by the issuing authority). Refined oil business license into a business license management.

- Q:Their own business to see this prospect is also good, I would like to ask about the understanding of the predecessors who, a small micro bio diesel refining equipment investment need to spend much money, the state is prohibited or encouraged in this regard? The most important thing is how to sell, thank you,

- Three, product (biodiesel, fatty acid methyl ester)1, the product can replace diesel oil, fuel, widely used in vehicles, ships.2, the product can replace soybean oil, epoxy methyl ester, widely used in chemical industry.

- Q:How biogas is produced

- Biogas is a kind of combustible gas produced by the fermentation of microorganisms under anaerobic conditions. As the gas was first found in the marsh, it was called methane. Livestock and poultry manure, straw, sewage and other organic substances in the sealed digesters, under anaerobic fermentation conditions, that is, a large variety of biogas fermentation microbial decomposition transformation, resulting in biogas. Biogas is a mixture of gases that can burn. Biogas is a combustible gas produced by anaerobic digestion of organic matter.

- Q:Waste oil refining biodieselHow much investment, conversion rate in the number?

- But the small scale of investment: Nissan 10 tons, with an annual output of 3000 tons in 2 million, excluding factory costs. I suggest that you at least to Nissan 20 tons, with an annual output of 6000 tons of scale, if the collection of raw materials is no problem, so that the size of the utilization rate of equipment, and the production cost is 6000 years worthwhile. Tons of scale, investment will be around 5 million.

- Q:What are the benefits and benefits of biogas digesters

- There are many advantages of biogas, mainly in the following aspects

- Q:Kitchen drainage can be methane

- Three) assembly 1, before installation, first feeding and discharge port to the upper half of the corresponding opening of the tank. 2, before installation, should carefully check whether there is damage to the methane pool, if any damage to timely repair. 3, put the pool, then check the bottom is flat, and put a layer of fine soil, poured some water, no stones and other hard objects. 4, when the pool will be on the hemisphere by the direction mark into the pits, flat, backfill, the second half is at the bottom of the outer side tamped, then the upper hemisphere button on the lower hemisphere according to mark direction. 5, enter the pool, the upper and lower half portion of the debris and sludge tank with clean, polished to a new crop with sandpaper, glass steel putty and the upper and lower half pool commissure greasy live. To the pool, glass steel putty will pool the second half in vitro pool commissure to be greasy, putty after curing, can be packed

- Q:To improve the production efficiency of diesel oil Bio oil technology

- It is a new trend to produce diesel oil by using engineering microalgae. The so-called engineering microalgae, which is constructed by genetic engineering technology, has opened up a new way for the production of diesel oil. The National Renewable Energy Laboratory (NREL) through modern biotechnology built "project microalgae", which is a "diatom Cyclotella Engineering" (Cyclotellacryptica), under laboratory conditions, the lipid content increased to more than 60% (the general lipid content under natural conditions for 5% - 20%, microalgae may also increase the production of outdoor) more than 40%. This is due to the high expression of acetyl coenzyme A carboxylase (ACC) gene in microalgae cells, and plays an important role in the control of lipid accumulation. At the present time, the suitable molecular carriers are being studied, and the ACC gene can be expressed in bacteria, yeast and plants, and the modified ACC

- Q:What is diesel oil refined

- Diesel (Diesel) also known as oil, is a product of oil refining. It is made up of different hydrocarbons. It is composed mainly of 9 to 18 carbon atoms of alkane, naphthenic or aromatic hydrocarbons.

- Q:How much does it cost to build a biogas digester?

- (2) proposed the construction scheme, construction drawings; (3) to build a pool of materials; (4) line; (5) excavation; (6) the formwork (external mold and an internal mold); (7) concrete, or brick, or precast concrete plate assembly (8); maintenance; (9) removal; (10) backfill; (11) sealing layer construction; (12) gas distribution pipe fittings, lamps, stoves installed; (13) pressure test and acceptance. All localities should according to local conditions, local materials, not force all. 2, the construction of large quantities of biogas digesters suitable? The biogas pool volume size (generally refers to the effective volume, the net volume of the main tank), should according to the daily number of varieties of raw materials, fermentation, gas production and gas production rate is determined, taking into account the quantity and use of biogas fertilizer. In rural areas, according to the average daily gas consumption per person 0.3 ~ 0.4 cubic meters, a family of 4 people, every day cooking, lighting need about 1.5 cubic meters of methane. If the use of good quality biogas lamps and biogas stoves, gas consumption can also be reduced. According to the practice of science and practice around the general requirements of an average amount of pig manure (about 5 kg) into the pool fermentation, that is, the planning of the construction of an effective volume of 1 cubic meters. Pool volume can be based on the local temperature, fermentation raw materials and other sources of specific planning.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Multifunctional Biomass Pellet Cooking Stove

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 unit

- Supply Capability:

- 10000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords