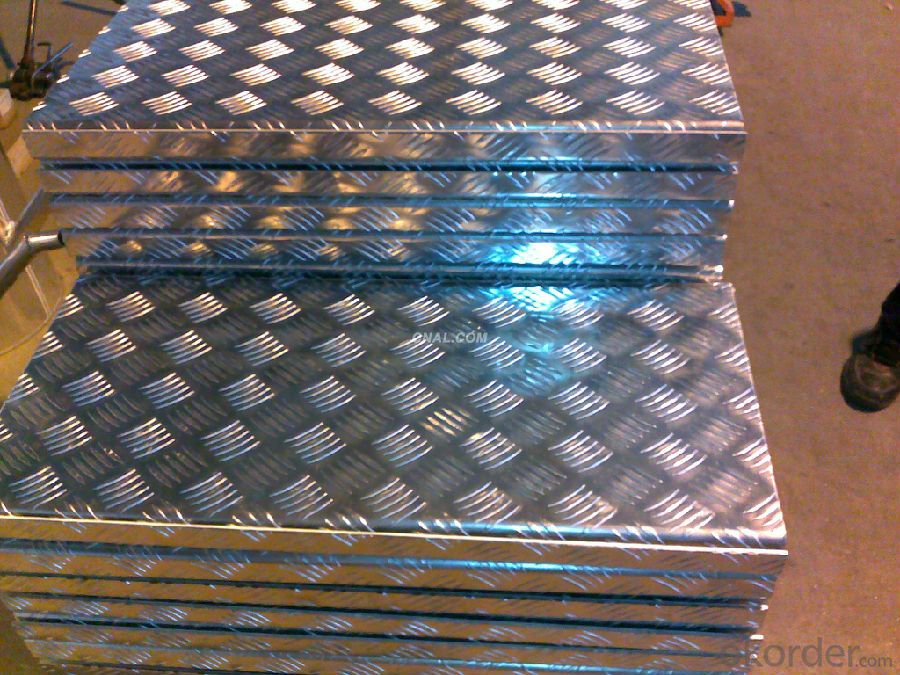

Aluminum Flooring Anti-slip Checker Embossed Sheet Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Aluminum Flooring Anti-slip Checker Embossed Sheet Plate

Description

Aluminium Sheet | ||||||

Alloy | Thickness(mm) | Width(mm) | Length(mm) | Temper | DC or CC | |

1050,1060,1070,1100,1235 | 0.2-4.0 | 400-1850 | 500-6000 | O,H12,H22,H14,H24,H16,H26,H18,H32 | DC, CC | |

4.0-150 | 1000-1900 | H112,H111 | DC | |||

3003,3004,3105 | 0.2-4.0 | 400-1850 | 500-6000 | O,H12,H22,H14,H24,H16,H26,H18,H32 | DC, CC | |

4.0-150 | 1000-1900 | H112,H111 | DC | |||

5052,5083,5754 | 0.2-4.0 | 400-1850 | 500-6000 | O,H12,H22,H14,H24,H16,H26,H18,H32 | DC | |

4.0-150 | 1000-1900 | H112, H111 | DC | |||

8011 | 0.08-0.20 | 400-1500 | 500-6000 | O,H12,H22,H14,H24,H16,H26,H18 | DC, CC | |

Packing | Export standard wooden packing | |||||

Application | Mainly in Construction , decoration, PCB materials, cover material, piping, refrigeration, air conditioner, automobile, etc. | |||||

MOQ | 5MT | |||||

Kind attention | Specifications can be customized as the customer’s requirements. | |||||

FAQ

Q: How can I request a product sample? A: The samples are free but freight should be collected. Please send sample list and courier account number by email.

Q: How can I request a product catalog? A: The hard copies of catalogs are free but freight should be collected. Please send courier account number by email. You are suggested to request a PDF catalog.

Q: Wha's your payment terms? A: One is T/T 30% before production and 70% against copy of B/L; the other is Irrevocable L/C 100% at sight.

Q: What's your trade terms? A: FOB, CNF(CFR), CIF, EXW.

Q: How long is the quality guarantee? A: All of our products have a period of quality guarantee since time of shipment. Please contact your salesman for more details, as different products enjoy different time of guarantee

- Q:Can aluminum sheet be used for medical applications?

- Yes, aluminum sheet can be used for certain medical applications. It is commonly utilized in medical equipment, such as imaging machines, as it is lightweight, durable, and has good electrical conductivity. However, it is important to note that aluminum's use in direct contact with the human body or in implants is limited due to potential health concerns and the availability of more suitable materials.

- Q:How do you cut aluminum sheets?

- There are various methods available for cutting aluminum sheets, depending on their thickness and size. Here, we will discuss some commonly used techniques: 1. Hand shears prove effective for thin aluminum sheets. These handheld tools feature sharp blades that can cut through the sheet by applying manual force. 2. For thicker aluminum sheets, power shears are a better option. These tools, either electric or pneumatic, have powerful blades that can effortlessly cut through the material. They are particularly useful for straight cuts. 3. When it comes to making curved or irregular cuts, a jigsaw with a metal-cutting blade comes in handy. Ensure you use a blade specifically designed for cutting metal. 4. Another method is using a circular saw with a carbide-tipped blade. This technique works well for straight cuts; however, it is crucial to securely clamp the sheet to avoid vibrations during cutting. 5. For precise shapes and sizes, Computer Numerical Control (CNC) machines are ideal. These machines utilize computer programs to control the cutting process, making them suitable for complex or repetitive cuts. Before cutting aluminum sheets, it is essential to prioritize safety. Wear appropriate gear such as gloves and safety glasses to protect yourself from sharp edges or metal shavings. Additionally, secure the sheet firmly in place using clamps or a vise to prevent any movement during cutting.

- Q:I'd like to have the aluminum on the etching front white. Do any of the experts know that?

- After anodizing, it turns white. If not, the aluminum plate should be white and spray polyester or fluorocarbon paint,

- Q:A 0.250-g sample of a magnesium-aluminum alloy dissolves completely in an excess of HCl (aq). When the liberated H2 is collected over water at 29 C and 752 torr, the volume is found to be 311 mL. The vapor pressure of water at 29 C is 30.0 torr. What is the mass percentage of aluminum in this alloy?

- I build aircraft,depends what aircraft it is. Some are made of a aluminum alloy mixed with other metal. Eurofighters outside skin is carbon fibre and contains many titanium parts. Then rivets hold everything together and they contain steel or alloy

- Q:Are aluminum sheets suitable for food contact applications?

- Aluminum sheets are indeed appropriate for food contact purposes. The food industry extensively employs aluminum because of its diverse advantageous characteristics. It is non-hazardous, non-responsive, and resistant to corrosion, thereby ensuring that it is safe to use alongside food. Aluminum sheets can be effortlessly molded into various shapes and sizes, rendering them suitable for a broad array of food packaging and cooking uses. Moreover, aluminum boasts exceptional thermal conductivity, facilitating efficient heat transfer during the cooking or baking process. It is also impervious to light, moisture, and oxygen, creating a protective barrier that preserves the freshness and quality of food. In general, due to their safety, adaptability, and durability, aluminum sheets are a highly favored option for food contact applications.

- Q:The diameter of a hole drilled through aluminum at 22°C is 7.50 mm. Find the diameter and the area of the hole at 89°C.

- Aluminum okorder / So 7.50 * 22.2 * 10-6 * 89 = 0.0111555 mm diameter increase (should only report 3 sig figs, so 7.51 mm). The area is then pi / 4 * d^2 = 44.31017 (so 44.3) mm^2

- Q:Can the export quality of China's aluminum plate meet the requirement of ASTM B 209? Is this requirement for our country? Master the exhibitions, O (a _ U) O thank you

- This is not quite clear, you Baidu once "work standard net" in "work standard net" check to know!

- Q:How is aluminum sheet made?

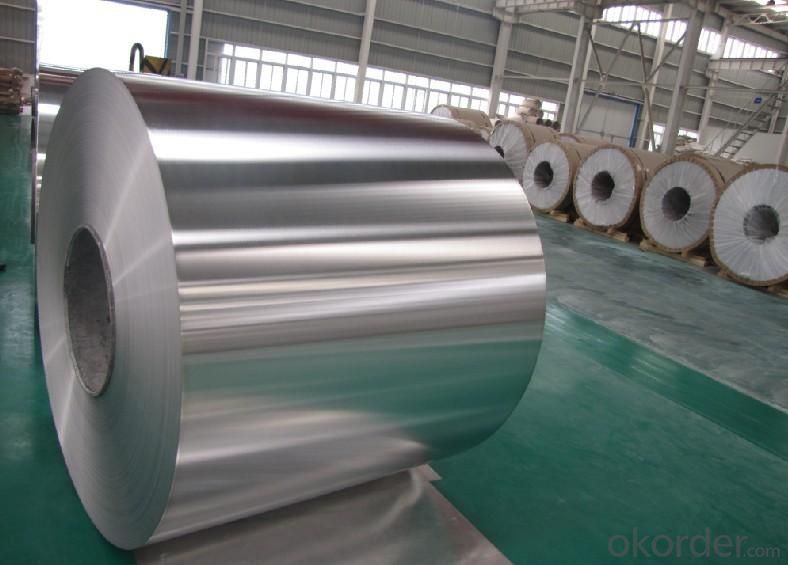

- Aluminum sheet undergoes a rolling process to be manufactured, known as rolling. This process entails passing a preheated aluminum ingot through a succession of rolling mills. The initial step involves heating the ingot to a specific temperature to enhance its malleability. Once heated, the ingot is then fed through a sequence of rolling mills, wherein it is continuously pressed and stretched to reduce its thickness and increase its length. The rolling mills consist of a pair of rotating cylinders with grooves on their surfaces. As the ingot passes through these cylinders, it undergoes compression and elongation, resulting in a thinner and longer sheet. This process is repeated multiple times, with each pass further reducing the sheet's thickness. To maintain the desired thickness and dimensions, the sheet is periodically subjected to annealing. This process involves heating the sheet to a specific temperature and gradually cooling it. Annealing helps alleviate internal stresses and ensures the sheet retains its desired properties. Once the desired thickness is achieved, the aluminum sheet is cooled, trimmed, and either cut into specific lengths or rolled into coils for further processing or distribution. The final product is a flat, thin, and versatile sheet of aluminum that finds applications in various industries, including construction, automotive, packaging, and electrical appliances.

- Q:What's the price of the 6mm aluminum sheet?

- The single aluminum plate is aluminum substrate, around the hem (can be customized size and shape) and install bracket forming a mounting edge, the surface of the fluorocarbon coating (various colors can be customized). Aluminum single board, white meters, Beijing reference price of 320 yuan / square meter, specific to take into account your size, material requirements, plate type and so on, generally see drawings quote.

- Q:Are aluminum sheets suitable for cladding?

- Yes, aluminum sheets are suitable for cladding due to their durability, lightweight nature, and corrosion resistance. Additionally, aluminum offers versatility in terms of design options and ease of installation, making it a popular choice for cladding applications in various industries.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Flooring Anti-slip Checker Embossed Sheet Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords