Aluminum Coil/Aluminum Circle/ Aluminum Sheet Famous Supplier from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Specification of Aluminum Circle

1) Alloy | AA1050, AA1060, AA1100, AA1235, AA1070, AA3104, AA3003, AA3004, AA3105, AA5005, AA5052, AA8011etc |

2) Temper | O/H12/H14/H16/H18/H32/H34/H36/H38//H22/H24/H26/H28/T6/T651/T3/T351 etc |

3) Thickness | 0.2mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | AluminIum |

7) Coil Inner diameter | 76mm, 152mm or as required |

2. Application of Aluminum Circle

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors.

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations.

(3).Advertisement: display platforms, signboards, fascia, shop fronts.

3. Feature of Aluminum Circle

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

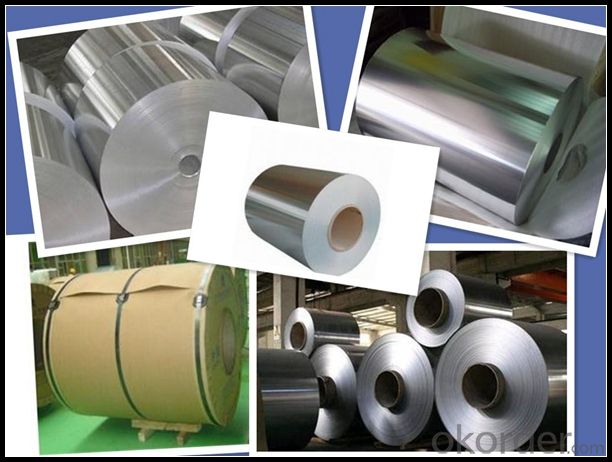

5. Image of Aluminum Circle

6. Package and shipping of

eye to wall

eye to the wall with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 30 to 35 days

2)What is the QC system:

We have QC staffs of 20 person and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) Where is your mainly market?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:Can aluminum coils be used in the production of aluminum doors?

- Aluminum doors can be produced using aluminum coils. Typically, aluminum coils serve as a raw material in the manufacturing process of aluminum doors. These coils are constructed from top-notch aluminum alloy and are available in varying thicknesses and widths. They can easily be molded into different shapes and sizes to fulfill the particular requirements of the doors. Furthermore, aluminum coils possess characteristics such as lightweightness, durability, and resistance to corrosion, making them an excellent option for door production. The coils are commonly subjected to various techniques like cutting, bending, and welding to fabricate the desired door components. All in all, aluminum coils offer numerous advantages in terms of versatility, strength, and aesthetics, which explains their popularity among aluminum door manufacturers.

- Q:Can aluminum coils be used for heat recovery systems?

- Indeed, heat recovery systems can utilize aluminum coils. Due to its exceptional heat conductivity, aluminum stands as an optimal option for heat transfer. In heat exchangers and heat recovery systems, aluminum coils frequently play a pivotal role in effectively transferring heat between different mediums. These coils are specifically engineered to maximize surface area, thereby enabling enhanced heat transfer. Furthermore, the lightweight and corrosion-resistant nature of aluminum renders it both durable and well-suited for a diverse range of applications within heat recovery systems.

- Q:What are the common coil inner diameters for aluminum coils?

- The specific application and industry requirements can cause the common coil inner diameters for aluminum coils to vary. Nonetheless, 150 mm (5.9 inches), 200 mm (7.9 inches), and 300 mm (11.8 inches) are frequently utilized inner diameters for aluminum coils. These inner diameters are often selected considering factors like the coil's size, weight, ease of handling, and compatibility with manufacturing equipment. It is crucial to acknowledge that these examples are merely a few, and the actual inner diameters may differ based on the unique needs of each industry or application.

- Q:What are the common surface defects or issues in aluminum coils?

- Some common surface defects or issues that can be found in aluminum coils include: 1. Scratches: These are visible marks on the surface of the coil caused by contact with abrasive materials or improper handling during production, transportation, or storage. 2. Streaks: Streaks are long, narrow lines or bands that appear on the surface of the coil. They are often caused by irregularities in the rolling process or the presence of impurities in the aluminum material. 3. Dents: Dents are localized depressions or deformations on the surface of the coil. They can occur due to mishandling, accidental impacts, or improper storage practices. 4. Corrosion: Aluminum is generally resistant to corrosion, but certain environmental conditions or exposure to corrosive agents can lead to the formation of oxide layers or pitting on the surface of the coil. 5. Edge cracks: These are cracks or fissures that occur along the edges of the coil. They can be caused by improper cutting or shearing techniques during the manufacturing process. 6. Surface roughness: Surface roughness refers to an uneven or bumpy texture on the surface of the coil. It can be a result of inadequate smoothing or finishing during the rolling or processing stages. 7. Oil stains: Oil stains are dark or discolored areas that appear on the surface of the coil. They can occur due to improper cleaning or lubrication during the production process. 8. Coil set: Coil set refers to the tendency of the coil to retain a curvature or shape after unwinding. It can be caused by stresses induced during rolling, coiling, or cooling, leading to a non-flat and uneven surface. 9. Roll marks: Roll marks are patterns or imprints left on the surface of the coil by the rolling mill or equipment. They can be caused by uneven pressure or improper alignment of the rolling tools. 10. Discoloration: Discoloration refers to changes in the color or appearance of the aluminum surface. It can occur due to exposure to high temperatures, chemical reactions, or oxidation. These surface defects or issues can negatively impact the appearance, quality, and performance of aluminum coils. Manufacturers and users should be aware of these defects and take appropriate measures to prevent or minimize their occurrence.

- Q:I bought a house that is older with aluminum windows, and the last owner did not seem to clean them for quite some time. The aluminum frames are a silvery milky white color and my neighbors that have the same windows look like chrome. I have brushed these windows with scrub brushes and green scouring pads even aluminum wheel cleaner, now my frame is a clean milky grey color, it just isnt polished like my neighbor has it, his is like chrome. I have tried silver polishes and this doesn't remove the grey film either - i need something stronger. Can anyone help???

- Your aluminium windows are possibly anodised which is a process carried out before the windows are assembled.Anodising is like a hard finished skin ,silver in your windows which was probably a semi sheen to begin with, some times this finish oxidises causing this white milky appearance. Anodising can be black,gold red, brown, and possibly other colours too used on motor cycles and sports equipment etc. Your neighbours window were probably anodised and polished (almost like chrome) again this would have been carried out before the windows were assembled. If this is the case no amount of cleaning will polish your anodising to a bright shiny finish. Contact an aluminium window installer/manufacturer as they have cleaning blocks, These look rather like a large pencil eraser containing metallic abrasive particles this may help. Your grey film is lightly to be the original siver turned dull. consult your aluminium window supplier to see if they can offer a better solution It may be possible to spray paint your window frames these would require acid etching and is a specialist procedure hope this is helpful good luck

- Q:How do you store aluminum coils to prevent damage?

- To prevent damage to aluminum coils, it is best to store them in a dry and well-ventilated area, away from direct sunlight and moisture. Storing them horizontally on a clean and flat surface, while using proper supports or holders to prevent rolling or bending, will also help maintain their integrity. Additionally, ensuring that the storage area is free from any sharp objects or potentially corrosive materials will further safeguard the aluminum coils from damage.

- Q:How are aluminum coils tested for thickness and flatness?

- Aluminum coils are typically tested for thickness and flatness using specialized equipment such as a thickness gauge and a flatness tester. The thickness gauge measures the thickness of the coil at various points to ensure it meets the required specifications. Meanwhile, the flatness tester uses laser technology or a similar method to measure the surface flatness of the coil, identifying any deviations or irregularities. These tests are crucial to ensure the quality and consistency of the aluminum coils before they are further processed or used in various applications.

- Q:How are aluminum coils tested for flatness?

- Aluminum coils are typically tested for flatness using a variety of methods, including visual inspection, mechanical measurement, and advanced technologies like laser scanning. The visual inspection involves examining the surface of the coil for any visible signs of waviness or distortion. Mechanical measurement techniques involve placing the coil on a flat surface and using specialized tools to measure its flatness by checking for any deviations from the ideal flat plane. Laser scanning is another method where a laser beam is directed across the surface of the coil, and the reflected beam is analyzed to determine the flatness of the coil. These testing methods ensure that aluminum coils meet the required flatness standards for their intended applications.

- Q:I am looking for a deoderant that doesn't contain aluminum that actually works. I have tried Tom's natural deoderant and didn't get to use it long enough to see if it worked because it really irritated my skin and caused it to burn and peel. I have also tried the one made by Adidas and it seemed to work pretty well through the winter months, but now that it is getting warm again I'm noticing that it isn't quite doing the job anymore.

- Try Crystal's they have the rock version which you have to wet before you use it and they also have he ready to use liquid. I find the liquid form to work best during the summer.

- Q:What are the potential applications of anodized aluminum coils?

- Anodized aluminum coils have numerous potential applications across various industries. One of the primary uses of anodized aluminum coils is in the construction industry. They are commonly used for cladding and façade systems, as the anodized coating enhances the durability, weather resistance, and aesthetic appeal of the aluminum. Anodized aluminum coils can withstand harsh environmental conditions, such as UV radiation, saltwater exposure, and extreme temperatures, making them an ideal choice for building exteriors. Another significant application of anodized aluminum coils is in the automotive industry. The anodized coating provides a protective layer that enhances the corrosion resistance of aluminum, making it suitable for various automotive components. It can be used for trim, body panels, window frames, and other parts that require both durability and an attractive appearance. Anodized aluminum coils also find use in the manufacturing of consumer electronics. The anodized coating improves the scratch resistance, electrical insulation, and heat dissipation properties of aluminum, making it suitable for electronic enclosures, heat sinks, and connectors. Additionally, the vibrant colors that can be achieved through anodization allow for customizable designs that appeal to consumers. Due to its lightweight nature and excellent heat conductivity, anodized aluminum coils are extensively used in the heating, ventilation, and air conditioning (HVAC) industry. They are commonly used for heat exchangers, air conditioning coils, and evaporator coils. The anodized coating provides protection against corrosion caused by moisture and other environmental factors, ensuring the longevity and efficiency of these HVAC components. Furthermore, anodized aluminum coils have applications in the food and beverage industry. The anodized coating provides a hygienic surface that is easy to clean and resistant to bacterial growth. It is used for food processing equipment, storage tanks, and packaging materials, ensuring the safety and quality of the products. Overall, the potential applications of anodized aluminum coils are vast and diverse, ranging from construction and automotive to electronics and food processing. The unique combination of durability, corrosion resistance, heat dissipation, and aesthetic appeal makes anodized aluminum coils a versatile material that finds use in numerous industries.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Coil/Aluminum Circle/ Aluminum Sheet Famous Supplier from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords