Aluminium Coil with Good Price and Excellent Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

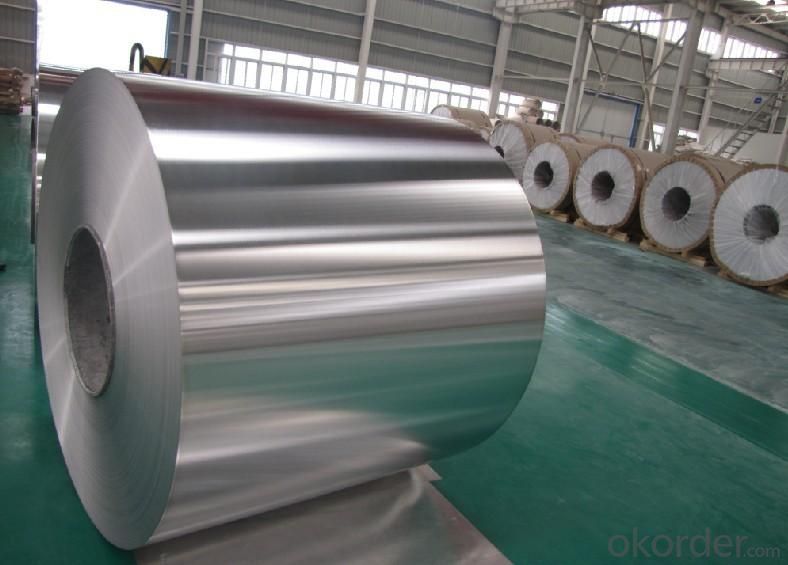

Structure of Aluminium Coil with Good Price and Excellent Quality Description:

Aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Coil with Good Price and Excellent Quality:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

Images of theAluminium Coil with Good Price and Excellent Quality:

Aluminium Coil with Good Price and Excellent Quality Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q:Can aluminum coils be used in solar thermal systems?

- Yes, aluminum coils can be used in solar thermal systems. Aluminum is a commonly used material for heat transfer in such systems due to its excellent thermal conductivity and corrosion resistance.

- Q:What are the different sizes available for aluminum coils?

- Aluminum coils come in various sizes to accommodate the diverse needs of different industries and applications. The sizes of aluminum coils can vary depending on factors such as intended use, manufacturing process, and customer preferences. In general, aluminum coils can be found in a range of thicknesses, typically spanning from 0.2mm to 8mm. The width of aluminum coils can range from a few inches to over 60 inches. As for length, aluminum coils can be customized, but standard lengths usually fall between 1000mm and 6000mm. The specific sizes of aluminum coils available may also be influenced by the manufacturing capabilities of the supplier or manufacturer. Some suppliers may offer a wide selection of sizes to cater to different customer demands, while others may have a more limited range. It is important to note that the availability of specific sizes may be subject to minimum order quantities or lead times. Therefore, it is advisable to consult with the supplier or manufacturer to inquire about the available sizes and any associated limitations or requirements. Overall, the assortment of sizes for aluminum coils allows customers the flexibility to select dimensions that best suit their specific applications and requirements.

- Q:why is aluminum used for railway lines?thanks x

- Aluminum is strong ans light weight.

- Q:What is the typical coefficient of friction for aluminum coils?

- The typical coefficient of friction for aluminum coils can vary depending on various factors such as the surface it is in contact with, the presence of lubricants, and the specific conditions of the application. However, aluminum generally exhibits a low coefficient of friction, usually ranging from 0.2 to 0.4.

- Q:Aluminum roll 220 kg.0.3 thickness, 500 width, roll diameter is how much?

- You can use the outside diameter, the inner diameter and the width to get the volume. You know the density and volume, and then you can find the weight naturally

- Q:Are there any special considerations for handling and storing aluminum coil scraps?

- There are specific factors to take into account when it comes to the handling and storage of aluminum coil scraps. To start with, it is crucial to handle these scraps with caution in order to prevent any potential injuries. Due to their sharp edges, workers should wear appropriate protective gear, such as gloves and safety glasses, while dealing with them. When it comes to storing aluminum coil scraps, it is of utmost importance to keep them in a dry and well-ventilated area. Moisture can cause corrosion in the aluminum, leading to the degradation of the material. To prevent this, it is recommended to store the scraps in a covered area or utilize moisture-absorbing materials. Moreover, it is essential to separate aluminum coil scraps from other materials, particularly those that can result in a chemical reaction or contamination. This is especially important if the aluminum coil scraps have been coated or treated with other substances. Furthermore, it is advisable to stack and store the aluminum coil scraps properly to avoid any damage or accidents. By stacking them in a stable manner and using appropriate equipment like pallets or racking systems, the risk of collapse or shifting can be minimized. Lastly, it is crucial to adhere to local regulations and guidelines regarding the handling and storage of aluminum coil scraps. These regulations may differ depending on the location and industry, so it is vital to stay informed and comply with any specific requirements. By taking these considerations into account, companies can ensure the secure handling, storage, and preservation of aluminum coil scraps, thereby reducing the possibility of accidents, damage, and deterioration.

- Q:How are aluminum coils used in the production of furniture and fixtures?

- Furniture and fixture production heavily relies on aluminum coils, which play a vital role in creating lightweight and long-lasting pieces. These coils are typically crafted from top-notch aluminum alloys, known for their exceptional strength-to-weight ratios and resistance to corrosion. One primary application of aluminum coils in furniture production involves constructing frames for chairs, tables, and other seating arrangements. Aluminum's lightweight nature simplifies handling and transportation, while still providing the necessary structural integrity. The coils can be easily molded, welded, and assembled into various frame designs, offering flexibility in creating different furniture styles. Furthermore, aluminum coils find frequent use in manufacturing fixtures like cabinets, shelves, and display racks. These coils can be cut, shaped, and bent to create customized components that perfectly suit specific design requirements. Aluminum's corrosion resistance ensures that these fixtures can endure exposure to moisture, making them suitable for both indoor and outdoor settings. Moreover, the utilization of aluminum coils in furniture and fixture manufacturing offers advantages that go beyond their physical properties. Aluminum is a highly recyclable material, making it an environmentally friendly choice. Its durability and low maintenance requirements also contribute to cost-effectiveness, reducing long-term expenses for manufacturers and consumers alike. To summarize, aluminum coils are indispensable in furniture and fixture production due to their lightweight, durable, and corrosion-resistant characteristics. Their versatility enables the creation of various designs, while their recyclability and cost-effectiveness make them a preferred choice in the industry.

- Q:I have a 94 Gt Mustang that has had a little work done to it so far. The boy I bought it from had an aftermarket cam put in it, had the heads ported and polished. He also had the heads shaved a little. My question is.........Would having aluminum heads with roller rocker arms installed help it enough to justify doing it. If it would, how Much would it help? I am not exactly sure how much life and duration my cam is running, but it idle pretty rough. I believe my compression is about 9.5 to 1.

- I also believe that the primary benefit of aluminum heads is weight savings...you can port and polish iron heads just the same. I also know that aluminum retains and dissipates heat differently than Iron.

- Q:What are the compositions of aluminum coil coating?

- Resin, pigment, auxiliary and solvent.

- Q:What are the acoustic properties of buildings using aluminum coils?

- The acoustic properties of buildings using aluminum coils can be influenced by various factors. Aluminum coils are commonly used in the construction industry for roofing, cladding, and insulation purposes. From an acoustic perspective, these properties can have both positive and negative impacts on the sound transmission within a building. One of the primary acoustic benefits of using aluminum coils is their ability to act as a reflective barrier for sound waves. When properly installed, aluminum coils can help prevent sound from penetrating through walls or ceilings, resulting in a reduction in external noise sources. This can be particularly beneficial in areas with high levels of noise pollution, such as urban environments or near busy roads. Additionally, aluminum coils can contribute to the overall sound insulation of a building. Due to their material properties, they can provide a certain level of soundproofing, especially when combined with other insulation materials. This can help maintain a comfortable and quiet indoor environment, allowing for improved concentration, productivity, and overall well-being of occupants. However, it is important to note that the acoustic properties of buildings using aluminum coils can also have limitations. Aluminum is a lightweight material compared to alternatives like concrete or brick, which means it may not provide as much mass to block sound transmission. Therefore, in situations where high sound insulation is required, additional measures such as double glazing, acoustic seals, or thicker wall constructions may be necessary. Furthermore, the use of aluminum coils can also affect the sound reverberation within a space. Due to their smooth and reflective surface, aluminum coils can potentially cause sound waves to bounce off, leading to increased echo and reverberation time. This can negatively impact speech intelligibility and acoustic comfort, especially in larger open-plan areas or rooms with high ceilings. Overall, while aluminum coils can offer certain acoustic advantages such as sound reflection and insulation, it is important to consider the specific requirements of each building project. Consulting with acoustic engineers or professionals can help ensure that the appropriate measures are taken to optimize the acoustic properties of buildings using aluminum coils, and to address any potential limitations.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Coil with Good Price and Excellent Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords