AA1070 C.C Mill Finished Aluminum Circles used for Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

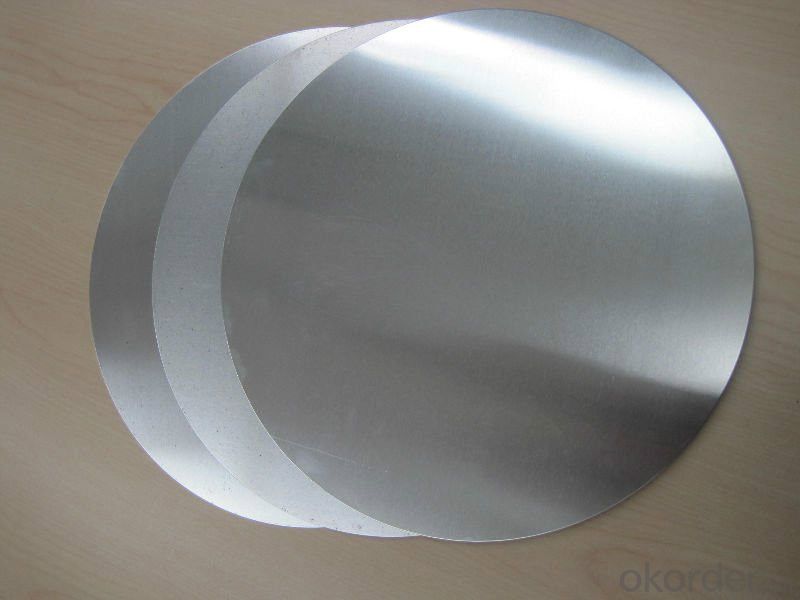

1.Structure of AA1070 C.C Mill Finished Aluminum Circles used for Cookware Description

AA1070 C.C Mill Finished Aluminum Circles used for Cookware is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

AA1070 C.C Mill Finished Aluminum Circles used for Cookware is one semi-finished aluminium material. This strip can be rolled down to aluminium foil.The final thickess can be 5-20 microns. Aluminium foil is soft, ductile and with a silver-white luster which can be widely used in a large scare of fields.

2.Main Features of AA1070 C.C Mill Finished Aluminum Circles used for Cookware

1)Surface Quality : be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks,

2)Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

3)Fine craftsmanship

4)Durable

5)Easy processing

3.AA1070 C.C Mill Finished Aluminum Circles used for Cookware Images

4.AA1070 C.C Mill Finished Aluminum Circles used for Cookware Specification

Alloy | AA1070 |

Temper | H14, H16, H18,O/F |

Thickness | 0.5mm -- 4mm |

Diameter | 200mm -- 1200mm |

Standard | GB/T 3880-2006 |

5. FAQ of AA1070 C.C Mill Finished Aluminum Circles used for Cookware

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

- Q:What grade of aluminum rod can be machined to teach high surface finish?

- I think no aluminum rod can be said produced higher smoothness, because will be machined out of aluminum oxidation in the air so that the finish grade did not say out of aluminum rod processing would have been good, all aluminum rods are the same as long as the feed and speed the car out of the car with the pin depth finish is very good. I think 6061-T1 made a very bright finish of our company is to use a medium grade finish up to 2

- Q:Calculation method for material cost of aluminium bars

- The chemical and physical properties of special aluminum has not only light weight, firmness, texture and good ductility, electrical conductivity, thermal conductivity, heat resistance and resistance to radiation, is an important basis for national economic development of raw materials.

- Q:Domestic professional aluminum rod peeling machine manufacturers are?

- Tangshan Hua Han foam aluminum Technology Development Co., Ltd.Bazhou Xin Xin Yuan Metallurgical Materials Co., Ltd.Shanxi Province, Yuncheng Longfei Nonferrous Metal Co.

- Q:What is the tensile strength of 2al12 aluminum bars?

- The tensile strength of 2A12 aluminum rod at room temperature. B (MPa): 390

- Q:Which material is hard, 7075 aluminum bar or 6065 aluminum bar?

- The hardness of 7075 aluminum bars is higher than 6065 aluminum bars

- Q:What should be used in grinding wheel and grinding fluid. Please enlighten master.Because the aluminum rod is soft in the grinding process of grinding cutting aluminum is easy to stick to the surface of the wheel, causing the surface blackening of aluminium rods or rough, we have tried what you said, not the key to solve the problem, I can have the method of experts can provide professional.We are processing the printer core shaft of the company, the product's high precision polishing may not be realized.

- The best surface finish grinding aluminum rod grinding to a degree I Ra0.30.

- Q:What is aluminum material called fine material? Is it made of aluminium bars?

- Aluminum bars (correctly rolled) into aluminum fine materials, aluminum bars are aluminum coarse materials.

- Q:How to refine the crystallization of cast aluminium bars

- Grain refining is one of the important processes in aluminum alloy casting and halo casting, and also one of the most effective measures to solve the casting defects such as porosity, coarse grain, bright crystal, feather crystal and crack. In the alloy casting, are non-equilibrium crystallization, all the impurities (including alloy elements) most concentrated at the grain boundaries, the smaller the grain boundary area, the greater the impurity elements (or alloy) uniformity is high. The impurity elements, high uniformity, can reduce its harmful effects, even small amounts of impurities harmful variable as beneficial; surface of alloy elements, high uniformity, can play a greater alloying elements capable of making full use of resources to achieve. The role of grain refinement, grain boundary area enlargement and element homogeneity can be explained by the following calculations. 1 and 2 metal blocks assuming the same volume of V, which is composed of cube grain, grain length of metal piece 1 for 2a, 2 of the length of a, then the metal piece 1 grain boundary area: metal piece 2 grain boundary area: metal block 2 block 1 of the grain boundary area is 2 times of metal.

- Q:Numerical control car 8mm aluminum bar material 3003, with what blade feeding speed, how much speed, cutting quantity for big master answer

- This requires the top speed of one of your lathes;If Aluminum Alloy about 200m processing line speed; 8mm aluminum bar is basically close to 8000 in turn, the general lathe is not up to the speed of about 100m; in accordance with the line speed, the machine speed is 4000 rpm; the speed of the lathe is too high;Aluminum alloy processing at around 100m line speed, personal feel low;It is recommended to look at the top speed of the lathe. Do it at about 80%-90% of the lathe's maximum speed;8mm has been relatively fine (do not know how much you have processing allowance); so pay attention to deformation;I personally suggest a single knife, about 0.5mm or so; feed at about 0.1 each turn (the surface does not require any words). If the surface is high, feed it downward.Hope that the above can help you.

- Q:The formula for calculating the length of aluminum rods for aluminum alloy production line

- Extrusion = (actual length / upsetting coefficient excess pressure) * extrusion coefficientExtrusion factor = extrusion barrel area / finished cross section areaMaterial length = number of nodes x fixed lengthEnd = extrusion lengthBar length = ((number of nodes x fixed length + cut end) / extrusion coefficient + residual pressure) * upsetting coefficient

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

AA1070 C.C Mill Finished Aluminum Circles used for Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches