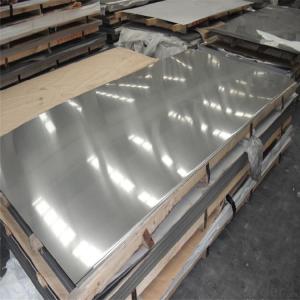

Sheet Metal Sheets 4X8

Sheet Metal Sheets 4X8 Related Searches

Cut Off Wheels For Metal Grinding Wheels For Metal Track Lighting For Walls Track Lighting With Plug Metal Stainless Steel Stainless Steel Nose Stud Industrial Led Track Lighting 24 Gauge Galvanized Sheet Metal 28 Gauge Galvanized Sheet Metal 4X8 Galvanized Sheet MetalHot Searches

Used Metal Folding Chairs For Sale Large Metal Containers For Sale Metal Shop Cabinets For Sale Metal Shipping Crates For Sale Galvanized Steel Scrap Price Fiber Sheet Price In India Galvanized Steel Prices Plastic Fiber Sheet Price Upvc Roofing Sheet Manufacturer In India China Geomembrane Roll Sheet Lasani Wood Sheet Price Rhino Roofing Sheet Price List Tinplate Sheet Price Mdf Price Per Sheet 4Mm Mdf Sheet 1220X2440Mm Price Grp Sheet Price Aluminum Sheet Stock Sizes Cost Of 4X8 Sheet Of Plywood Cost Of Drywall Per Sheet Buy Sheet PlasticSheet Metal Sheets 4X8 Supplier & Manufacturer from China

Okorder.com is a professional Sheet Metal Sheets 4X8 supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Sheet Metal Sheets 4X8 firm in China.Hot Products

FAQ

- Yes, stainless steel sheets can be used for decorative panels. The versatility, durability, and sleek appearance of stainless steel make it a popular choice for various decorative applications, including panels. It can be used to create modern and stylish designs in both residential and commercial settings.

- Due to its unique composition and the presence of a protective oxide layer, stainless steel sheets have the ability to resist corrosion. Stainless steel is comprised of iron, chromium, and other alloying elements like nickel and molybdenum. Chromium is particularly essential for the corrosion resistance of stainless steel. When exposed to oxygen, chromium creates a thin and invisible oxide layer on the surface of the stainless steel, which is referred to as the passive layer. This passive layer acts as a barrier, preventing oxygen and moisture from reaching the underlying metal and safeguarding it against corrosion. This layer is the reason why stainless steel is called "stainless," as it remains free from rust and corrosion. The chromium oxide layer has the ability to self-repair and reform if it gets damaged or scratched, ensuring continuous protection for the stainless steel. This characteristic enables stainless steel sheets to be utilized in various environments, including those with high humidity, exposure to chemicals, and even saltwater. Furthermore, alloying elements such as nickel and molybdenum enhance the corrosion resistance of stainless steel. Nickel enhances the stability and strength of the passive layer, while molybdenum improves resistance against pitting and crevice corrosion. Moreover, surface finishes like polishing or passivation can provide additional protection against corrosion for stainless steel sheets. These processes eliminate any contaminants or impurities from the surface and promote the formation of a stronger and more uniform passive layer. In conclusion, the combination of chromium, other alloying elements, and the protective oxide layer makes stainless steel sheets extremely resistant to corrosion, ensuring durability and longevity in a wide range of applications.

- Is there a big price difference between the SUS304 stainless steel plate and the drawing plate?

- Wire drawing is the surface of a steel processing methods, 304 and 201 steel plates can be processed drawing, the price difference is not very large, it will be more than a processing fee. The steel plate after drawing is more likely to rust than the steel plate on the 2B surface.

- There are several types of stainless steel sheet edges available, including mill edge, slit edge, deburred edge, rounded edge, and beveled edge. Each type has its own unique characteristics and is used for specific applications.

- Food preparation surfaces can indeed utilize stainless steel sheets. The reason behind stainless steel's popularity for such surfaces is its remarkable characteristics. Being non-porous, it avoids the absorption of any liquids or bacteria that can contaminate the food. Moreover, stainless steel exhibits resistance to corrosion, staining, and rusting, thereby ensuring its durability and longevity for food preparation surfaces. Furthermore, stainless steel can be easily cleaned due to its ability to withstand high temperatures and resistance to most cleaning agents. This fact makes it a hygienic option for food preparation surfaces, as it allows for thorough sanitization to prevent bacterial growth. In conclusion, stainless steel sheets provide a secure and practical alternative for food preparation surfaces.

- Architectural wire mesh can indeed be made from stainless steel sheets. This material is highly versatile and widely used in architecture because of its durability, attractive appearance, and resistance to corrosion. By transforming stainless steel into sheets, it becomes easily manipulable and can be woven into wire mesh panels suitable for various architectural purposes, including building facades, interior partitions, sunscreens, and balustrades. The use of stainless steel sheets for architectural wire mesh allows for the creation of intricate and visually appealing designs, while also providing strength, stability, and longevity to the structure. Furthermore, customization options are available for stainless steel wire mesh, including mesh size, wire diameter, and finish, ensuring that it meets the specific requirements of each architectural project.

- Yes, stainless steel sheets are suitable for elevator buttons. Stainless steel is a popular choice for elevator buttons due to its durability, resistance to corrosion, and easy maintenance. Elevator buttons are constantly touched by numerous people throughout the day, and stainless steel can withstand the wear and tear of frequent use without losing its aesthetic appeal. Additionally, stainless steel is easy to clean and sanitize, making it a hygienic choice for elevator buttons. Overall, stainless steel sheets are an excellent material for elevator buttons, providing both durability and a sleek, modern appearance.

- Stainless steel sheets do not require any special maintenance, but they do need regular cleaning to maintain their appearance and prevent corrosion. Unlike other materials, stainless steel is resistant to staining, rust, and corrosion, making it relatively low-maintenance. However, it is important to clean stainless steel sheets regularly to remove dirt, debris, and fingerprints that can diminish their shine. To clean stainless steel sheets, simply use a soft cloth or sponge with mild soap and warm water, avoiding abrasive cleaners or scrub brushes that can scratch the surface. Additionally, it is recommended to dry the sheets thoroughly after cleaning to prevent water spots or marks. By following these simple cleaning instructions, stainless steel sheets can maintain their beauty and functionality for years to come.