254SMO stainless steel forgings/round bar/rod/pipe fittings

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 260000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Stainless steel bars,profiles,beams

Product Information:

(Physical Properties)

Density | 8.24g/cm3 |

Fusion Point | 1320-1390°C |

Standard:ASTM A182 | |

Mechanical Property

Alloy and state | Tensile Strength | Yield Strength | Elongation | Hardness |

RM N/MM2 | RP0.2N/MM2 | A5% | HB | |

Thin plate/strips | >=690 | >=310 | ó=35 | <=223< span=""> |

Sheet | >=655 | >=310 | ó=35 | <=223< span=""> |

254SMO Application field:

1.Petroleum, petrochemical equipment, such as the petrochemical equipment in the corrugated pipe

2. Pulp bleaching equipment, such as pulp digester, bleaching equipment, filter scrubber for bucket cylinder and pressure roller, etc..

3. Power plant flue gas desulfurization device, the main use of the site: absorption tower tower body, flue, block door, inside, spray system, etc..

4.Marine systems or sea water treatment, such as the power plant in the use of seawater cooling of thin walled condensate pipeline, seawater desalination processing equipment, even in the sea may not flow equipment can also be used.

5. Desalination industry, such as salt or desalination equipment

6. Heat exchangers, especially in the working environment of chlorine ion exchanger.

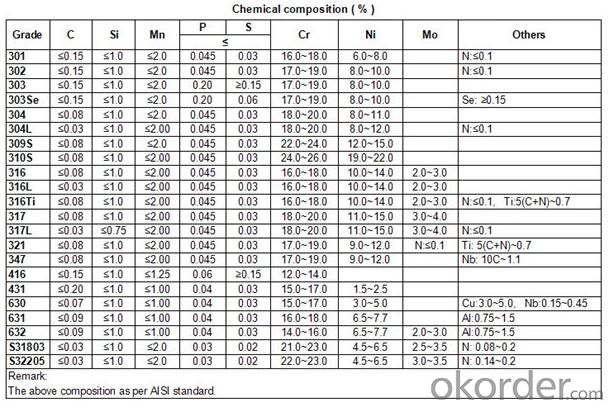

| 200 series: 201, 202 | |

| 300 series: 303, 304, 304L,321, 310S, 316, 316L | |

| 400 series: 410, 420, 430 | |

| Standard | AISI, ASTM, DIN, GB, JIS, SUS |

| Diameter | 2mm-300mm |

| Length | 1 meters to 9 meters or random |

| Surface | bright, black |

| Treatment | Hot rolled, cold drawn, Annealed, Grinding |

| Packing | Standard sea-worthy package or as required |

| Trade Terms | EXW, FOB, CFR, CIF |

| MOQ | 200 KGs Stainless Steel Round Bar |

| Payment | 30% deposit in advance, balance against copy of BL or irrevocable L/C at sight |

| Delivery | Usually 15-20 days upon receipt of deposit for 1 FCL |

Product Size Detail:

| Main operation | Main steel grade | Available size(mm) | Monthly capacity(mt) | Length(mm) | ||

| OEM | Stainless steel | 40~500 | 1500 | 4000~8000 | ||

| Hot | 303 303Cu 304/L 310S 316/L 321 416 420 | 12 ~200 | 3000 | 4000~7000 | ||

| 17-4PH WLA510 | ||||||

| ST Bar | 321 304/L 316/L 310S 17-4PH WLA510 | 19~110 | 2000 | 4000~7000 | ||

CD Bar | Round bar | 303 303CU 304/L 316/L 416 420 17-4PH WLA510 | 4.76~100 | 500 | 2500~6500 | |

| Square bar | 303 303CU 304/L 316/L 416 17-4PH WLA510 | 4.76~75 | 180 | 2500~6500 | ||

| Hex bar | 303 303CU 304/L 316/L 416 17-4PH WLA510 | 4.76~75 | 180 | 2500~6500 | ||

| CG Bar | 303 303CU 304/L 316/L 416 420 17-4PH WLA510 | 4.76~100 | 500 | 2500~6500 | ||

Specificate:

Our Advantages

• All products are made of high-quality imported raw materials.

• Our products are certified by ISO9001:2008 authentication quality systems.

• we are nominated as the AAA enterprise by Jiangsu government.

• Quick Response to Your Enquiry.

- Q:Can stainless steel bars be used in power generation applications?

- Yes, stainless steel bars can be used in power generation applications. Stainless steel is highly resistant to corrosion, making it a suitable material for use in power generation environments that involve exposure to water, steam, or chemicals. It is commonly used in power plants for applications such as turbine components, heat exchangers, boilers, and condensers. Stainless steel bars offer excellent strength, durability, and heat resistance, making them ideal for withstanding the high temperatures and pressures often found in power generation systems. Additionally, stainless steel bars can be easily fabricated and welded, allowing for customization and easy installation in various power generation equipment. Overall, the corrosion resistance, strength, and versatility of stainless steel bars make them a reliable and efficient choice for power generation applications.

- Q:Are stainless steel bars suitable for architectural cladding?

- Yes, stainless steel bars are suitable for architectural cladding. Stainless steel is a durable and corrosion-resistant material, making it ideal for exterior applications. Additionally, its sleek and modern appearance adds an aesthetic appeal to architectural designs.

- Q:Can stainless steel bars be used in corrosive environments?

- Yes, stainless steel bars can be used in corrosive environments. Stainless steel is known for its excellent corrosion resistance properties, making it suitable for use in environments where other materials may corrode or deteriorate. The chromium content in stainless steel forms a protective oxide layer on the surface, which acts as a barrier against corrosion and rusting. Additionally, stainless steel bars can be further alloyed with elements such as molybdenum, nickel, or titanium to enhance their resistance to specific types of corrosive environments, such as those containing acids, salts, or chlorides. Overall, stainless steel bars are widely used in various industries, including chemical processing, marine, food processing, and pharmaceutical, where they are exposed to corrosive substances or environments.

- Q:Do stainless steel bars require regular maintenance?

- Yes, stainless steel bars do require regular maintenance. While stainless steel is known for its resistance to corrosion and staining, it is not completely immune to damage or wear. Regular maintenance helps to preserve the appearance and integrity of stainless steel bars. This typically involves cleaning the bars regularly to remove dirt, grime, and any potential contaminants that may cause corrosion. Additionally, it is important to inspect the bars for any signs of damage or rust and address them promptly. Regular maintenance also includes applying protective coatings or finishes to enhance the durability and longevity of stainless steel bars. Overall, although stainless steel bars are relatively low maintenance compared to other materials, regular care and attention are still necessary to ensure their optimal performance and longevity.

- Q:Can stainless steel bars be used in food processing applications?

- Yes, stainless steel bars can be used in food processing applications. Stainless steel is a preferred material in the food industry due to its corrosion resistance, durability, and ease of cleaning. It does not react with food substances, preventing contamination and maintaining hygiene standards.

- Q:Can stainless steel bars be used in the manufacturing aftermarket?

- Yes, stainless steel bars can be used in the manufacturing aftermarket. Stainless steel is known for its durability, corrosion resistance, and ease of maintenance, making it a popular choice for various applications in the manufacturing industry. Its versatility allows it to be used in a wide range of aftermarket products, such as automotive parts, machinery components, and building materials.

- Q:What are the different surface finishes available for stainless steel bars?

- Stainless steel bars come in various surface finishes, each with its own distinct characteristics and advantages. Some of the commonly used surface finishes are as follows: 1. Mill Finish: This is the standard finish achieved during the manufacturing process of stainless steel bars. It has a dull appearance and shows visible machining marks. Mill finish is typically employed in applications where aesthetics are not a major concern. 2. Bright Annealed (BA) Finish: To achieve this finish, the stainless steel bar is annealed in a controlled environment, resulting in a bright and reflective surface. BA finish is often used for decorative purposes and in applications where corrosion resistance is crucial. 3. Brushed Finish: Also referred to as satin finish, brushed finish is created by brushing the surface of the stainless steel bar with a fine abrasive material. It exhibits a subtle linear pattern and offers good corrosion resistance. This finish is commonly utilized in architectural and decorative applications. 4. Polished Finish: In order to achieve a polished finish, the surface of the stainless steel bar is polished using increasingly finer abrasives until a mirror-like appearance is obtained. This finish provides excellent corrosion resistance and is favored in industries where hygiene and cleanliness are essential, such as the food and pharmaceutical sectors. 5. Bead Blasted Finish: Bead blasting involves projecting small glass or ceramic beads onto the surface of the stainless steel bar at high speeds. This process creates a uniform matte finish with a slightly rough texture. Bead blasted finish is often employed in industrial applications where a non-reflective surface is desired. 6. Etched Finish: Etching entails applying an acid or chemical solution to the surface of the stainless steel bar to create patterns or designs. This finish is commonly used for decorative purposes and can produce unique visual effects. These are just a few examples of the many surface finishes available for stainless steel bars. The choice of finish depends on specific application requirements, including aesthetics, corrosion resistance, and functionality.

- Q:Can stainless steel bars be used in elevator components?

- Elevator components can incorporate stainless steel bars, which are favored for their numerous desirable qualities. Stainless steel possesses high strength, resistance to corrosion, and durability, rendering it appropriate for diverse elevator parts. Stainless steel bars find application in elevator components like guide rails, brackets, handrails, and support structures, all of which are pivotal for the secure and seamless functioning of elevators. These bars furnish the necessary strength and stability to bear the weight of both the elevator car and its occupants. Furthermore, stainless steel's corrosion resistance assumes paramount importance in elevator settings, where exposure to elements like moisture, humidity, and chemicals is common. By thwarting rusting, stainless steel helps extend the lifespan of elevator components. The use of stainless steel bars in elevator components also offers an aesthetic advantage. Stainless steel imbues elevators with a sleek and contemporary appearance, thereby enhancing their visual appeal. Additionally, stainless steel can be effortlessly cleaned and maintained, ensuring that elevators remain in pristine condition. To conclude, stainless steel bars can undoubtedly be employed in elevator components. Their high strength, resistance to corrosion, durability, and aesthetic appeal render them a suitable choice for various elevator parts, thereby guaranteeing the safe and dependable operation of elevators.

- Q:Do stainless steel bars have good resistance to chloride stress corrosion cracking?

- Yes, stainless steel bars have good resistance to chloride stress corrosion cracking.

- Q:Can stainless steel bars be used in water treatment plants?

- Certainly, water treatment plants can utilize stainless steel bars. Stainless steel boasts exceptional resistance to corrosion, rendering it an optimal material for instances involving contact with water or other corrosive agents. Within water treatment plants, stainless steel bars find application in a multitude of areas, including screens, filters, pumps, valves, and piping systems. The corrosion resistance of stainless steel guarantees prolonged durability and diminished maintenance requirements in comparison to alternative materials. Additionally, stainless steel stands as a hygienic and effortlessly cleanable option, rendering it highly suitable for water treatment plants where cleanliness and purity hold utmost importance.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

254SMO stainless steel forgings/round bar/rod/pipe fittings

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 260000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords