ASTM Standard 200,300,400 Series Stainless Steel Sheet/Plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 150000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

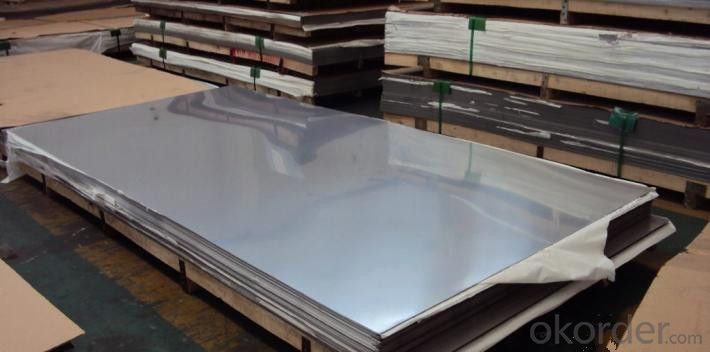

ASTM Standard 200,300,400 stainless steel sheet /Plate

1.Product introduction

We are the manufacturer! We produce stainless steel products with high quality & very competitive price!Please feel free to contact us for more information! | |

Product Name | ASTM Standard 200,300,400 Series Stainless Steel Sheet/Plate |

Standard | JIS AISI ASTM GB DIN |

Grade | 200/300/400 Series |

Thickness | 0.2mm-100mm |

Width | 100mm-2000mm |

Length | According to clients’ requirement |

Surface Finish | 2B ,BA ,8K ,NO4,NO2, NO1 ,Hair line ,EMBOSSED... |

Technique | Cold rolled ,Hot rolled |

Package | Seaworthy packing or as the consumers’ demand |

Application | Be used in manufacture of medical equipment, auto parts, heat-resistant kitchen utensils, electrical accessories , construction decoration ,etc |

Trade Term | FOB CIF |

Payment | T/T , L/C |

LoadingPort | Shanghai |

Delivery Time | 3-7days,mainly in accordance with the quantity |

Report | Material report ,Mechanical performance report |

Certification | ISO9001 |

2.Surface finishes and characteristic

Surface finish | Characteristics and application |

NO.2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

NO.1 |

The surface is finished by heat treatment and pickling or processes corresponding thereto after hot rolling.

|

NO.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria,but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators,door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror,kitchen apparatus,ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Know more about trade...

Payment term: 1. 30% T/T in advance, and the balance against B/L copy

2. 100% irrevocable LC at sight.

Shipment date: Within 15-20 days after advance payment or receipt of LC

Trade term: 1. FOB Shanghai port, China.

2. CIF Discharging port

Guarantee& Service: Mill Test Certificate is supplied with shipment, and Third Part Inspection is acceptable.

Packing: standard export packing (plastic package to prevent water or plywood case to strengthen package)

- Q:Can stainless steel bars be used in the pulp and paper industry?

- Yes, stainless steel bars can be used in the pulp and paper industry. Stainless steel is highly durable and resistant to corrosion, making it suitable for use in the harsh and corrosive environments found in pulp and paper mills. It can be used in various applications such as pulp digester vessels, paper machine components, and chemical processing equipment. Its high strength and resistance to chemicals and moisture make it an ideal choice for the pulp and paper industry.

- Q:Can stainless steel bars be used in chemical processing equipment?

- Indeed, chemical processing equipment can indeed utilize stainless steel bars. The chemical industry widely embraces stainless steel due to its remarkable resistance to corrosion. It exhibits resilience against numerous chemicals, acids, and alkalis, thereby rendering it suitable for managing a variety of corrosive substances. Stainless steel bars are customarily employed in the fabrication of chemical processing equipment, including reactors, vessels, pumps, valves, and piping systems. They offer exceptional sturdiness, durability, and the capacity to endure extreme temperatures, making them exceptionally well-suited for enduring the rigorous conditions within chemical processing environments. Furthermore, stainless steel can be effortlessly cleansed and sterilized, thereby ensuring a sanitised and uncontaminated processing environment.

- Q:What are the dimensional tolerances for stainless steel bars?

- The dimensional tolerances for stainless steel bars can vary depending on the specific grade and size of the bar. Generally, the dimensional tolerances for stainless steel bars are specified as per industry standards such as ASTM A276 or ASTM A484. For the diameter or size of the bar, the tolerance is typically specified as a plus or minus value. The tolerance can range from a few thousandths of an inch to a few hundredths of an inch, depending on the size and grade of the bar. For example, a 1-inch diameter stainless steel bar may have a tolerance of +/- 0.005 inches, while a 3/8-inch diameter bar may have a tolerance of +/- 0.002 inches. In addition to the diameter tolerance, other dimensional tolerances may also be specified for stainless steel bars. These can include straightness tolerance, which ensures that the bar does not have excessive bow or bend, and length tolerance, which specifies the allowable variation in the overall length of the bar. It is important to note that these tolerances are intended to ensure that the stainless steel bars meet the required dimensional specifications for their intended use. These tolerances may vary depending on the application and specific requirements of the customer. Therefore, it is always recommended to consult the relevant standards and specifications or discuss with the manufacturer or supplier to determine the exact dimensional tolerances for the specific stainless steel bars required.

- Q:Can stainless steel bars be used in mining conveyors?

- Yes, stainless steel bars can be used in mining conveyors. Stainless steel is known for its high strength, corrosion resistance, and durability, making it suitable for the harsh conditions and heavy loads typically encountered in mining operations. Additionally, stainless steel bars can withstand extreme temperatures and are resistant to abrasion, making them an ideal choice for mining conveyor systems.

- Q:Can stainless steel bars be used in tennis racket frames?

- Tennis racket frames can incorporate stainless steel bars, which are renowned for their strength, durability, and resistance to corrosion. This exceptional material is widely used in diverse applications, including tennis racket frames, owing to its remarkable properties. The presence of stainless steel bars in the racket enhances its stability and rigidity, thereby improving its performance and minimizing vibrations during gameplay. Furthermore, the low maintenance requirements of stainless steel make it an appealing option for tennis racket frames since it can endure harsh weather conditions and regular use without succumbing to rust or deterioration. Nonetheless, it is important to acknowledge that the selection of materials for tennis racket frames may vary depending on personal preferences and playing style. Therefore, it is highly advisable to seek guidance from a tennis equipment specialist or coach to obtain the optimal recommendation.

- Q:What are the different heat treatment methods for stainless steel bars?

- There are several different heat treatment methods that can be used for stainless steel bars, depending on the desired properties and application requirements. Some of the most common heat treatment methods for stainless steel bars include: 1. Annealing: This is a process of heating the stainless steel bars to a specific temperature and then slowly cooling them. Annealing helps to relieve internal stresses, improve ductility, and restore the material's mechanical properties. 2. Quenching and tempering: This two-step process involves heating the stainless steel bars to a high temperature and then rapidly cooling them in a quenching medium such as oil or water. This step hardens the material, making it stronger and more wear-resistant. The bars are then tempered by reheating to a lower temperature to reduce brittleness and improve toughness. 3. Solution treatment: This method involves heating the stainless steel bars to a high temperature and holding them at that temperature for a specific period of time. This process helps to dissolve any carbides or other precipitates in the material, resulting in improved corrosion resistance and enhanced mechanical properties. 4. Aging: Aging is a heat treatment method that is typically used for precipitation-hardening stainless steels. It involves heating the stainless steel bars to a specific temperature and then holding them at that temperature for a prolonged period of time. This process allows for the precipitation of fine particles within the material, increasing its strength and hardness. 5. Stress relieving: Stress relieving is a heat treatment method used to minimize residual stresses in the stainless steel bars. It involves heating the bars to a specific temperature and then slowly cooling them. This process helps to reduce the risk of distortion or cracking during subsequent machining or forming operations. These heat treatment methods can be combined or modified to achieve specific properties and performance characteristics required for different applications. It is important to consult with material experts and follow industry standards and guidelines to ensure the appropriate heat treatment is applied to stainless steel bars.

- Q:Can stainless steel bars be used in the power plant industry?

- In the power plant industry, stainless steel bars are highly valued due to their remarkable corrosion resistance, outstanding strength, and exceptional durability. This material proves suitable for a wide range of applications within this industry. Notably, these bars are utilized in the construction of crucial structural components like support beams, frames, and platforms. Moreover, they play a vital role in the manufacturing of essential equipment such as turbines, boilers, heat exchangers, and condensers. It is also worth mentioning that stainless steel bars are commonly employed in the creation of piping systems, where their resistance to corrosion and ability to withstand high temperatures are of utmost importance. Given their ability to endure extreme conditions prevalent in power plants, including high pressure, elevated temperatures, and exposure to various chemicals, these bars are consistently relied upon by professionals in this industry.

- Q:Can stainless steel bars be laser engraved?

- Certainly! Laser engraving is a highly effective technique for etching and marking stainless steel bars. It offers great versatility and precision, applicable to a wide range of materials, including stainless steel. By employing a powerful laser beam, the surface of the stainless steel bar can be intricately and permanently engraved. This method is particularly well-suited for branding, personalization, and identification purposes. Nevertheless, it is worth mentioning that the outcome of the laser engraving process on stainless steel bars can be influenced by variables such as the stainless steel's type and thickness, as well as the power and configuration of the laser machine employed.

- Q:What are the applications of stainless steel bars in the semiconductor industry?

- Due to their exceptional characteristics and properties, stainless steel bars have found numerous applications in the semiconductor industry. In order to withstand demanding operational conditions and maintain high levels of cleanliness, the semiconductor industry requires materials that meet specific requirements. Here are some key applications of stainless steel bars in the semiconductor industry: 1. Wafer fabrication: Stainless steel bars play a crucial role in the production of semiconductor wafers, providing a stable and reliable platform for the fabrication process. By resisting corrosion and high temperatures, stainless steel ensures the integrity and quality of the wafers during processing. 2. Vacuum systems: Stainless steel bars are utilized in vacuum systems found in semiconductor manufacturing equipment. These bars are commonly used to construct chambers, flanges, and fittings that are exposed to high vacuum conditions. With its low outgassing properties and high strength, stainless steel is an ideal material for maintaining a clean and controlled vacuum environment. 3. Cleanroom equipment: Stainless steel bars are commonly used in the construction of cleanroom equipment such as workbenches, storage racks, and shelves. The smooth surface of the material prevents particle accumulation, ensuring the cleanliness of the environment, which is critical in semiconductor manufacturing. 4. Chemical handling: Stainless steel bars are resistant to a wide range of chemicals, making them suitable for handling various corrosive substances used in semiconductor fabrication processes. They are often used in the construction of chemical delivery systems and storage tanks, ensuring the safety and integrity of the chemicals. 5. Electroplating and etching: Stainless steel bars are employed as anodes or cathodes in electroplating and etching processes. Their excellent conductivity and resistance to chemical reactions make them an ideal choice for these applications. 6. Heating elements: Stainless steel bars with high-temperature resistance are used as heating elements in semiconductor manufacturing equipment. These bars efficiently transfer heat to specific components or processes, ensuring precise temperature control during various stages of semiconductor fabrication. In conclusion, stainless steel bars are crucial components in the semiconductor industry, offering durability, cleanliness, and versatility for various applications. Their resistance to corrosion, high temperatures, and chemicals make them essential in the manufacturing processes of semiconductors, ensuring consistent quality and reliability.

- Q:Are stainless steel bars suitable for industrial pumps?

- Yes, stainless steel bars are suitable for industrial pumps. Stainless steel is a highly durable and corrosion-resistant material, making it an ideal choice for various industrial applications including pumps. It offers excellent resistance to rust, corrosion, and chemicals, ensuring the longevity and reliability of the pump system. Stainless steel bars are also known for their strength and heat resistance, allowing them to withstand high-pressure and high-temperature environments often encountered in industrial operations. Additionally, stainless steel bars can be easily machined and fabricated to meet specific design requirements, making them versatile for use in different types of industrial pumps. Overall, stainless steel bars provide the necessary qualities and performance needed for efficient and long-lasting operation in industrial pump systems.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

ASTM Standard 200,300,400 Series Stainless Steel Sheet/Plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 150000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords