All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

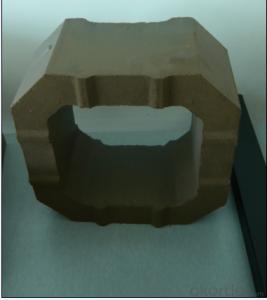

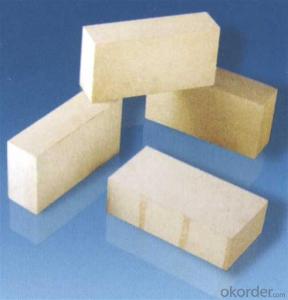

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

What are the common refractory brick shapes used in cement preheaters?

The common refractory brick shapes used in cement preheaters include straight bricks, arch bricks, wedge bricks, and special-shaped bricks such as herringbone bricks.

What are the refractory requirements for power plants?

The refractory requirements for power plants refer to the specific characteristics and properties that the materials used in the construction of power plant furnaces, boilers, and other high-temperature components must possess. These requirements include high thermal resistance, resistance to thermal shock, excellent insulation properties, chemical resistance to corrosive gases and ash, and mechanical strength to withstand the extreme operating conditions of power plants. The refractory materials used must be able to withstand and contain high temperatures, provide thermal insulation to improve energy efficiency, and ensure the safe and reliable operation of power generation equipment.

How do refractory bricks contribute to the insulation of furnaces?

Refractory bricks contribute to the insulation of furnaces by being able to withstand and retain high temperatures without deforming or cracking. This insulation property prevents heat from escaping the furnace, maintaining a high temperature inside and reducing heat loss to the surroundings.

Wholesale Refractory Bricks from supplier in Venezuela

We understand the unique needs and challenges of the Venezuelan market and have tailored our services to meet them. Our team of experts is well-versed in local regulations and requirements, ensuring a smooth and hassle-free procurement process.

When you choose us as your supplier, you can expect high-quality products that meet international standards. Our Refractory Bricks are sourced from reputable manufacturers and undergo rigorous quality control procedures to ensure their durability and performance.

In addition to sales and quotations, we also offer comprehensive technical support to assist you throughout your project. Our team of engineers is available to provide guidance on product selection, installation, and maintenance, ensuring optimal performance and longevity of your refractory materials.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and expertise. This enables us to offer competitive pricing, reliable supply chain management, and efficient logistics solutions.

Whether you are in need of refractory bricks for industrial furnaces, kilns, or any other high-temperature applications, we have the right solutions for you. Contact us today to discuss your requirements and let us provide you with a comprehensive and convenient procurement experience.

When you choose us as your supplier, you can expect high-quality products that meet international standards. Our Refractory Bricks are sourced from reputable manufacturers and undergo rigorous quality control procedures to ensure their durability and performance.

In addition to sales and quotations, we also offer comprehensive technical support to assist you throughout your project. Our team of engineers is available to provide guidance on product selection, installation, and maintenance, ensuring optimal performance and longevity of your refractory materials.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and expertise. This enables us to offer competitive pricing, reliable supply chain management, and efficient logistics solutions.

Whether you are in need of refractory bricks for industrial furnaces, kilns, or any other high-temperature applications, we have the right solutions for you. Contact us today to discuss your requirements and let us provide you with a comprehensive and convenient procurement experience.

Hot Search

- Monolithic Refractories in Pakistan

- Ceramic Fiber Products in British

- Refractory Bricks in Slovakia

- Raw Materials For Refractory in Azerbaijan

- Refractory Bricks in Georgia

- Refractory Bricks in Cambodia

- Refractory Bricks in Zambia

- Monolithic Refractories in Qatar

- Raw Materials For Refractory in Sudan

- Ceramic Fiber Products in Tonga