All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What measures are taken to ensure the safety of workers in tinplate manufacturing?

In tinplate manufacturing, several measures are taken to ensure the safety of workers. Firstly, comprehensive training programs are provided to educate employees about potential hazards and safety protocols. This includes proper handling and use of machinery, personal protective equipment (PPE), and emergency procedures. Secondly, regular inspections and maintenance of equipment are conducted to identify any potential safety risks and address them promptly. Additionally, safety protocols such as lockout/tagout procedures are implemented to prevent accidental startup of machinery during maintenance or repair work. Furthermore, a strong safety culture is fostered within the workplace, encouraging workers to report hazards and near misses, and actively participate in safety committees or programs. Overall, a combination of training, inspections, maintenance, and a proactive approach towards safety ensures the well-being of workers in tinplate manufacturing.

How is tinplate used in the production of decorative and collectible art pieces?

Tinplate is commonly used in the production of decorative and collectible art pieces due to its versatility and aesthetic appeal. It is often shaped into various forms such as trays, boxes, or figurines, which are then adorned with intricate designs or patterns using different artistic techniques like embossing or painting. The smooth and shiny surface of tinplate provides an ideal canvas for artists to showcase their creativity and transform these art pieces into visually stunning and valuable collectibles.

What are the challenges associated with cutting and shaping tinplate into complex forms?

One of the main challenges associated with cutting and shaping tinplate into complex forms is the material's inherent rigidity. Tinplate is a relatively stiff and inflexible material, making it difficult to manipulate into intricate shapes without the risk of deformation or breakage. Additionally, the use of traditional cutting methods such as shearing or punching may not provide the desired precision required for complex forms, leading to inconsistencies or imperfections in the final product. Another challenge is the need for specialized tools and machinery to effectively cut and shape tinplate, which can be expensive and require specific expertise to operate. Therefore, achieving complex forms with tinplate often requires careful planning, advanced techniques, and experienced craftsmen to overcome these challenges successfully.

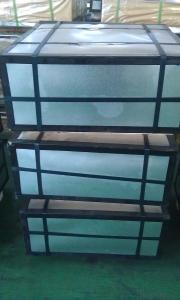

Wholesale Tinplate from supplier in Tunisia

Whether you are in the food packaging, beverage can, or general packaging industry, we have a wide range of Tinplate products to meet your specific requirements. Our offerings include Tinplate coils, sheets, and strips in various thicknesses and finishes.

As a leading supplier, we understand the importance of timely delivery and consistent quality. With our vast network of manufacturing facilities and strategic partnerships, we can ensure that your Tinplate products reach you on time and in perfect condition.

In addition to our product offerings, we also provide comprehensive sales support services. Our team of experts is available to guide you through the entire procurement process, from understanding your needs and specifications to providing competitive quotations. We can also assist you in selecting the right Tinplate products for your applications, ensuring optimal performance and cost-effectiveness.

Furthermore, our technical support services are designed to help you make informed decisions and overcome any challenges you may face. Whether you need assistance with product selection, technical specifications, or troubleshooting, our experienced engineers are here to help. We can also provide customized solutions to meet your specific requirements.

With our extensive experience in the Tunisian market, we have developed valuable insights and strong relationships with local partners. This allows us to provide you with tailored solutions that take into account local regulations, market trends, and customer preferences.

At CNBM, we are committed to delivering exceptional customer service and ensuring your success. Contact us today to discuss your Tinplate procurement needs in Tunisia and let us provide you with comprehensive solutions that meet your requirements and exceed your expectations.

As a leading supplier, we understand the importance of timely delivery and consistent quality. With our vast network of manufacturing facilities and strategic partnerships, we can ensure that your Tinplate products reach you on time and in perfect condition.

In addition to our product offerings, we also provide comprehensive sales support services. Our team of experts is available to guide you through the entire procurement process, from understanding your needs and specifications to providing competitive quotations. We can also assist you in selecting the right Tinplate products for your applications, ensuring optimal performance and cost-effectiveness.

Furthermore, our technical support services are designed to help you make informed decisions and overcome any challenges you may face. Whether you need assistance with product selection, technical specifications, or troubleshooting, our experienced engineers are here to help. We can also provide customized solutions to meet your specific requirements.

With our extensive experience in the Tunisian market, we have developed valuable insights and strong relationships with local partners. This allows us to provide you with tailored solutions that take into account local regulations, market trends, and customer preferences.

At CNBM, we are committed to delivering exceptional customer service and ensuring your success. Contact us today to discuss your Tinplate procurement needs in Tunisia and let us provide you with comprehensive solutions that meet your requirements and exceed your expectations.