All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

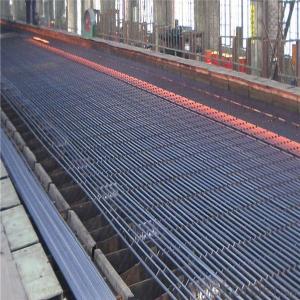

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How are steel rebars integrated into the construction of sewage and wastewater treatment plants in urban areas?

Steel rebars are integrated into the construction of sewage and wastewater treatment plants in urban areas by being used to reinforce the concrete structures. These rebars are strategically placed within the concrete to provide strength and stability, ensuring that the structures can withstand the loads and pressures associated with the treatment processes and environmental conditions.

How are steel rebars inspected for quality and compliance with industry standards?

Steel rebars are inspected for quality and compliance with industry standards through various methods, including visual inspection, dimensional checks, and mechanical testing. Visual inspection involves examining the surface of rebars for any visible defects such as cracks, rust, or deformities. Dimensional checks ensure that rebars meet the required size and shape specifications. Mechanical testing involves conducting tensile and bending tests to evaluate the strength and flexibility of the rebars. Additionally, rebars may undergo chemical analysis to verify their composition and adherence to specific alloy requirements. Overall, these inspections help ensure that steel rebars meet the necessary quality and compliance standards in the industry.

What is the significance of fire resistance in steel-reinforced concrete structures in high-temperature environments?

The significance of fire resistance in steel-reinforced concrete structures in high-temperature environments is crucial for ensuring the structural integrity and safety of the building. Steel, although incredibly strong, loses its load-bearing capacity at high temperatures, while concrete maintains its strength. By incorporating steel reinforcement within the concrete, the structure gains the advantage of both materials. The fire resistance of the concrete acts as a protective barrier, insulating the steel from the high temperatures and preventing it from reaching its critical failure point. This fire resistance allows the structure to maintain its stability and prevent the collapse or deformation of the building, giving occupants more time to evacuate safely and firefighters more time to extinguish the fire.

What factors influence the choice between straight and bent steel rebars in construction?

There are several factors that influence the choice between straight and bent steel rebars in construction. Firstly, the structural requirements of the project play a significant role. If the design calls for complex shapes or curved elements, bent rebars are preferred as they can be customized to fit the specific requirements. Secondly, the ease of installation and handling is considered. Straight rebars are generally easier to handle and place in simple structures, whereas bent rebars may require more effort and skill. Additionally, the cost and availability of each type of rebar can impact the decision. Straight rebars are typically more readily available and cost-effective, while bent rebars may be more expensive due to the customization involved. Ultimately, the choice between straight and bent steel rebars depends on the specific needs of the project, structural design, and budget constraints.

Wholesale Steel Rebars from supplier in Austria

We are a Steel Rebars supplier serving the Austria, mainly engaged in the sale, quotation, and technical support services of various Steel Rebars products in the Austria region. We are a subsidiary platform of the Fortune Global 500 company CNBM, able to provide you with one-stop Steel Rebars procurement services in the Austria. Not only do we have a wide range of Steel Rebars products, but after years of market development in the Austria, we can also provide valuable experience for your projects.