All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

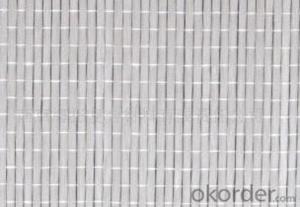

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How is fiberglass mat tissue cut to size?

Fiberglass mat tissue is typically cut to size using either manual or automated cutting methods, such as scissors, knives, or cutting machines. The mat tissue is laid out on a flat surface, and the desired dimensions are measured and marked. Then, the cutting tool is used to carefully cut along the marked lines to achieve the desired size.

Is fiberglass mat tissue suitable for underground applications?

Yes, fiberglass mat tissue is suitable for underground applications. It is commonly used in underground infrastructure such as pipes and tanks due to its high strength, corrosion resistance, and durability against harsh underground conditions.

Can fiberglass mat tissue be used for filtration applications?

Yes, fiberglass mat tissue can be used for filtration applications. It is commonly used in the filtration industry due to its excellent filtration properties, high strength, and durability. The mat tissue is capable of trapping and removing solid particles, making it suitable for various filtration processes such as air and water filtration.

What are the different manufacturing processes used for fiberglass mat tissue?

There are several manufacturing processes used for fiberglass mat tissue, including the wet-laid process, the dry-laid process, and the stitch-bonding process. The wet-laid process involves dispersing the fiberglass in water, forming a uniform slurry, which is then drained and dried to create the mat tissue. The dry-laid process involves carding the fiberglass fibers and forming a web, which is then bonded together using heat or chemicals. The stitch-bonding process involves mechanically interlocking the fiberglass fibers using a needle-punching technique. These different processes offer varying levels of strength, durability, and flexibility in the final fiberglass mat tissue.

Wholesale Fiberglass Mat Tissue from supplier in Sudan

Whether you require Fiberglass Mat Tissue for roofing, insulation, or any other application, our team of experts is here to assist you every step of the way. We understand the unique challenges and requirements of the Sudanese market and strive to provide tailored solutions that meet your specific needs.

Our sales team is dedicated to providing you with competitive pricing and timely quotations, ensuring that you receive the best value for your investment. We work closely with our network of suppliers to ensure a reliable and consistent supply of high-quality Fiberglass Mat Tissue, delivering on time and within budget.

In addition to our sales services, we also offer comprehensive technical support to assist you in choosing the right Fiberglass Mat Tissue for your project. Our team of experienced engineers and technicians can provide guidance on product selection, installation techniques, and troubleshooting, ensuring that you achieve optimal results.

As a subsidiary of CNBM, one of the largest building materials companies in the world, we have access to a vast global network of resources and expertise. This allows us to stay at the forefront of industry trends and innovations, enabling us to offer the latest and most advanced Fiberglass Mat Tissue products in Sudan.

At our company, customer satisfaction is our top priority. We strive to build long-term relationships with our clients based on trust, reliability, and exceptional service. Whether you are a contractor, distributor, or end-user, we are committed to meeting your Fiberglass Mat Tissue needs and exceeding your expectations.

Contact us today to discuss your Fiberglass Mat Tissue requirements in Sudan and discover how our expertise and product range can benefit your projects.

Our sales team is dedicated to providing you with competitive pricing and timely quotations, ensuring that you receive the best value for your investment. We work closely with our network of suppliers to ensure a reliable and consistent supply of high-quality Fiberglass Mat Tissue, delivering on time and within budget.

In addition to our sales services, we also offer comprehensive technical support to assist you in choosing the right Fiberglass Mat Tissue for your project. Our team of experienced engineers and technicians can provide guidance on product selection, installation techniques, and troubleshooting, ensuring that you achieve optimal results.

As a subsidiary of CNBM, one of the largest building materials companies in the world, we have access to a vast global network of resources and expertise. This allows us to stay at the forefront of industry trends and innovations, enabling us to offer the latest and most advanced Fiberglass Mat Tissue products in Sudan.

At our company, customer satisfaction is our top priority. We strive to build long-term relationships with our clients based on trust, reliability, and exceptional service. Whether you are a contractor, distributor, or end-user, we are committed to meeting your Fiberglass Mat Tissue needs and exceeding your expectations.

Contact us today to discuss your Fiberglass Mat Tissue requirements in Sudan and discover how our expertise and product range can benefit your projects.