All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

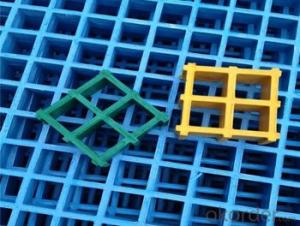

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How is FRP pultrusion different from other manufacturing processes?

FRP pultrusion is different from other manufacturing processes in several ways. Firstly, it is a continuous manufacturing process where a composite material, typically fiberglass reinforced plastic (FRP), is pulled through a heated die to shape it into a desired profile. This continuous process allows for high production rates and consistent quality.

Secondly, pultrusion enables the creation of complex profiles with consistent cross-sectional dimensions and performance properties throughout the length of the product. This is achieved by carefully controlling the resin impregnation and fiber alignment during the pultrusion process.

Additionally, FRP pultrusion offers exceptional strength-to-weight ratio, corrosion resistance, and durability. The resulting products have high strength characteristics, making them suitable for various applications in industries such as construction, aerospace, automotive, and marine.

Compared to other manufacturing processes like extrusion or injection molding, which are suitable for producing simpler shapes, pultrusion excels in creating intricate profiles with superior mechanical properties. Its ability to produce long, continuous lengths also reduces the need for joints or connections, resulting in stronger and more reliable products.

Are FRP pultrusion profiles resistant to transmission fluid?

Yes, FRP pultrusion profiles are generally resistant to transmission fluid. The corrosion-resistant properties and high chemical resistance of FRP make it an ideal material for applications that involve exposure to various chemicals, including transmission fluid.

What are the cost advantages of using FRP pultrusion profiles?

There are several cost advantages of using FRP pultrusion profiles. Firstly, FRP pultrusion profiles are lightweight and easy to transport, which reduces shipping costs. Secondly, they have a long lifespan and require minimal maintenance, resulting in lower life-cycle costs compared to traditional materials. Additionally, FRP pultrusion profiles are corrosion-resistant, eliminating the need for expensive coatings or treatments. Lastly, the manufacturing process for FRP pultrusion profiles is highly efficient, leading to lower production costs and overall affordability.

Wholesale FRP Pultrusion Profiles from supplier in Slovenia

We are a FRP Pultrusion Profiles supplier serving the Slovenia, mainly engaged in the sale, quotation, and technical support services of various FRP Pultrusion Profiles products in the Slovenia region. We are a subsidiary platform of the Fortune Global 500 company CNBM, able to provide you with one-stop FRP Pultrusion Profiles procurement services in the Slovenia. Not only do we have a wide range of FRP Pultrusion Profiles products, but after years of market development in the Slovenia, we can also provide valuable experience for your projects.

Hot Search

- Fiberglass Chopped Strand in Czech Republic

- Fiberglass Mesh Cloth in Jordan

- Composite Pipes in Paraguay

- FRP Pultrusion Profiles in Malawi

- Fiberglass Mat Tissue in Bahrain

- Fiberglass Fabrics in Guinea

- Fiberglass Mesh in Turkmenistan

- Composite Tank in Egypt

- Fiberglass Mesh tape in Kazakhstan

- Polymer in Libya