All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the different cutting methods for stainless steel coils?

There are several cutting methods commonly used for stainless steel coils. These include shearing, laser cutting, abrasive cutting, and plasma cutting. Each method offers its own advantages and disadvantages, depending on factors such as precision, speed, and cost.

What is the length range of stainless steel coil?

The length range of stainless steel coil can vary, but it is typically found between 1000mm to 6000mm.

What are the different types of surface treatments for stainless steel coil (nitriding, carburizing, etc.)?

Some of the different types of surface treatments for stainless steel coil include nitriding, carburizing, passivation, electroplating, and powder coating. Nitriding involves introducing nitrogen to the surface of the steel to increase its hardness and wear resistance. Carburizing is a process where carbon is diffused into the steel to create a harder surface layer. Passivation helps to enhance the corrosion resistance of stainless steel by forming a protective oxide layer on the surface. Electroplating involves depositing a layer of another metal onto the stainless steel coil to improve its appearance or provide additional protection. Powder coating is a method where a dry powder is applied to the surface and then baked to create a durable and decorative finish.

What is the thermal conductivity of stainless steel coils?

The thermal conductivity of stainless steel coils can vary depending on the specific grade of stainless steel used. On average, stainless steel has a thermal conductivity ranging from 14 to 20 watts per meter-kelvin (W/m.K).

What are the common alloying elements used in stainless steel coils?

The common alloying elements used in stainless steel coils are chromium, nickel, and molybdenum.

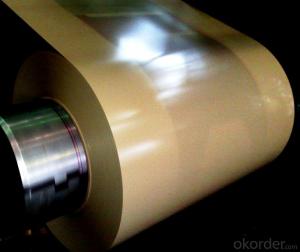

Wholesale Stainless Steel Coil from supplier in Slovenia

With our expertise in Stainless Steel Coil solutions, we are committed to providing the highest quality products and services to our clients in Slovenia. Our comprehensive range of Stainless Steel Coil products ensures that we can meet the diverse needs of various industries, including construction, manufacturing, and engineering.

At our company, we understand the importance of competitive pricing for our clients. We strive to offer cost-effective solutions without compromising on the quality of our products. Our accurate quotations ensure transparency and help our clients plan their budgets effectively.

In addition to competitive pricing, we also provide reliable technical support to assist our clients throughout their projects. Our team of experts is always ready to address any queries or concerns and offer guidance based on their extensive knowledge and experience in the field.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to vast resources and advanced technologies. This enables us to deliver top-notch services and ensure a seamless procurement experience for our clients in Slovenia.

With years of market presence in Slovenia, we have gained valuable insights into the local industry. Our understanding of the market dynamics and customer preferences allows us to provide personalized solutions tailored to the specific requirements of each project.

When you choose us as your partner for Stainless Steel Coil needs in Slovenia, you can trust us to deliver high-quality products, competitive pricing, accurate quotations, reliable technical support, and invaluable insights. We are dedicated to building long-term relationships with our clients by consistently exceeding their expectations. Contact us today to discuss your Stainless Steel Coil requirements and experience the difference of working with a trusted supplier.

At our company, we understand the importance of competitive pricing for our clients. We strive to offer cost-effective solutions without compromising on the quality of our products. Our accurate quotations ensure transparency and help our clients plan their budgets effectively.

In addition to competitive pricing, we also provide reliable technical support to assist our clients throughout their projects. Our team of experts is always ready to address any queries or concerns and offer guidance based on their extensive knowledge and experience in the field.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to vast resources and advanced technologies. This enables us to deliver top-notch services and ensure a seamless procurement experience for our clients in Slovenia.

With years of market presence in Slovenia, we have gained valuable insights into the local industry. Our understanding of the market dynamics and customer preferences allows us to provide personalized solutions tailored to the specific requirements of each project.

When you choose us as your partner for Stainless Steel Coil needs in Slovenia, you can trust us to deliver high-quality products, competitive pricing, accurate quotations, reliable technical support, and invaluable insights. We are dedicated to building long-term relationships with our clients by consistently exceeding their expectations. Contact us today to discuss your Stainless Steel Coil requirements and experience the difference of working with a trusted supplier.