All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

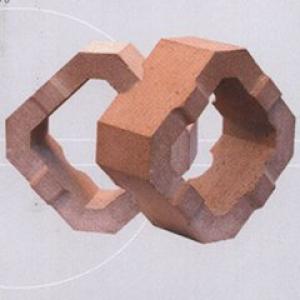

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

What are the common refractory brick materials used in the industry?

The common refractory brick materials used in the industry are silica, alumina, magnesia, zirconia, and fireclay.

What are the common sizes of refractory bricks?

The common sizes of refractory bricks vary depending on their intended use and application. However, some common sizes include standard dimensions of 9 inches by 4.5 inches by 2.5 inches, as well as 9 inches by 4.5 inches by 3 inches and 9 inches by 4.5 inches by 1.25 inches. These sizes are widely used in various industries and provide a good starting point for selecting refractory bricks for different thermal insulation and lining needs.

How do refractory bricks perform in waste-to-energy plants?

Refractory bricks perform exceptionally well in waste-to-energy plants due to their high heat resistance and ability to withstand corrosive environments. These bricks are specially designed to handle the extreme temperatures generated during the combustion process and the aggressive chemical composition of waste materials. They effectively line the combustion chamber, boilers, and other high-temperature areas, ensuring durability, thermal insulation, and long-term performance in waste-to-energy plants.

Can refractory bricks be used in copper smelting?

Yes, refractory bricks can be used in copper smelting. Refractory bricks are specifically designed to withstand high temperatures and harsh chemical environments, which makes them suitable for use in copper smelting furnaces where high temperatures are required to melt and separate copper from its ores. These bricks help to insulate the furnace and maintain the desired temperature, ensuring efficient and effective copper smelting processes.

What are the common refractory brick shapes used in chemical production?

The common refractory brick shapes used in chemical production include straight bricks, arch bricks, wedge bricks, and special shapes like key bricks and burner blocks.

Wholesale Refractory Bricks from supplier in Rwanda

Our team of experts is dedicated to understanding your specific requirements and offering tailored solutions to meet your needs. Whether you are looking for standard refractory bricks or customized solutions, we have the capability to deliver high-quality products that meet international standards.

We have established partnerships with reputable manufacturers, ensuring that our refractory bricks are of the highest quality and reliability. Our close collaboration with these manufacturers allows us to offer competitive prices and timely delivery, ensuring that your projects stay on schedule and within budget.

In addition to our sales services, we also provide comprehensive technical support. Our team of engineers and technicians are available to assist you with any technical queries or challenges you may face during the installation or operation of the refractory bricks. We provide guidance on proper usage, maintenance, and troubleshooting, ensuring the longevity and efficiency of your refractory brick installations.

We understand the importance of efficient communication and prompt responses in the procurement process. Our dedicated sales team is committed to providing timely quotations and addressing any inquiries or concerns you may have. We strive to build long-term relationships with our clients based on trust, reliability, and excellent customer service.

Choose us as your supplier of refractory bricks in Rwanda, and experience a seamless procurement process backed by the expertise and resources of a Fortune Global 500 company. Contact us today for more information or to request a quotation.

We have established partnerships with reputable manufacturers, ensuring that our refractory bricks are of the highest quality and reliability. Our close collaboration with these manufacturers allows us to offer competitive prices and timely delivery, ensuring that your projects stay on schedule and within budget.

In addition to our sales services, we also provide comprehensive technical support. Our team of engineers and technicians are available to assist you with any technical queries or challenges you may face during the installation or operation of the refractory bricks. We provide guidance on proper usage, maintenance, and troubleshooting, ensuring the longevity and efficiency of your refractory brick installations.

We understand the importance of efficient communication and prompt responses in the procurement process. Our dedicated sales team is committed to providing timely quotations and addressing any inquiries or concerns you may have. We strive to build long-term relationships with our clients based on trust, reliability, and excellent customer service.

Choose us as your supplier of refractory bricks in Rwanda, and experience a seamless procurement process backed by the expertise and resources of a Fortune Global 500 company. Contact us today for more information or to request a quotation.

Hot Search

- Monolithic Refractories in Malawi

- Ceramic Fiber Products in Malaysia

- Refractory Bricks in Peru

- Raw Materials For Refractory in Venezuela

- Raw Materials For Refractory in Cambodia

- Raw Materials For Refractory in Papua New Guinea

- Ceramic Fiber Products in Belize

- Refractory Bricks in Qatar

- Monolithic Refractories in Comoros

- Monolithic Refractories in Swaziland