All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What is the role of aluminum coils in the production of aluminum wiring for electrical systems?

Aluminum coils play a critical role in the production of aluminum wiring for electrical systems. These coils serve as the primary raw material, as they are processed and formed into the desired shape and size for electrical wiring. The coils are typically subjected to various manufacturing processes, including drawing, annealing, and insulation application, to ensure their electrical conductivity, durability, and safety. Ultimately, the aluminum coils are transformed into aluminum wiring that is widely used in residential, commercial, and industrial electrical installations.

What are the advantages of using aluminum coils in solar panels?

There are several advantages of using aluminum coils in solar panels. Firstly, aluminum is lightweight, making it easier to transport and install the panels. Secondly, aluminum is highly resistant to corrosion, ensuring the longevity and durability of the panels even in harsh weather conditions. Additionally, aluminum has excellent thermal conductivity, allowing for efficient heat dissipation and minimizing the risk of overheating. Lastly, aluminum is a sustainable material as it is 100% recyclable, reducing the environmental impact of solar panel production and disposal.

What are the steps involved in the coil slitting process for aluminum coils?

The coil slitting process for aluminum coils typically involves the following steps:

1. Uncoiling: The aluminum coil is unwound from its original packaging and placed on the slitting machine.

2. Straightening: The coil is passed through a set of rollers to remove any bends or imperfections, ensuring a smooth and flat surface.

3. Slitting: The coil is fed through a set of circular blades or knives that cut it into narrower strips of the desired width. The number of blades and their spacing determines the number and width of the final strips.

4. Recoiling: The newly slit aluminum strips are wound onto separate coils, each containing a specific width of material.

5. Edge Trimming: If necessary, the edges of the slit strips may be trimmed to remove any uneven or jagged edges, ensuring a clean and uniform appearance.

6. Inspection: The slit coils are visually inspected for any defects or irregularities, such as scratches or surface damage, to ensure they meet the required quality standards.

7. Packaging: The slit coils are carefully packaged and labeled for shipment or storage, protecting them from damage during transportation.

Overall, the coil slitting process for aluminum coils involves uncoiling, straightening, slitting, recoiling, edge trimming, inspection, and packaging to produce narrower strips of aluminum with precise dimensions.

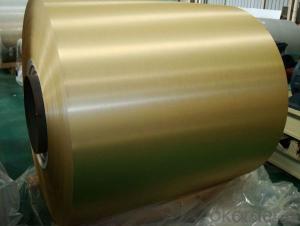

Wholesale Aluminum Coils from supplier in Philippines

With our dedication to customer satisfaction, we strive to deliver high-quality Aluminum Coils that meet international standards. Our products undergo thorough testing and quality checks to ensure their durability and performance. Whether you need Aluminum Coils for construction, automotive, or packaging applications, we have the right solution for you.

In addition to our wide range of products, we also offer value-added services such as customization, fabrication, and logistics. Our team of experts can work closely with you to understand your specific requirements and provide tailored solutions that fit your needs. We have a strong network of suppliers and partners, enabling us to efficiently handle large-scale projects and meet tight deadlines.

At our company, we prioritize customer satisfaction and strive to exceed your expectations at every step. We are committed to building long-term relationships with our clients by offering reliable products, competitive prices, and exceptional service. Our dedicated team is always ready to assist you with any inquiries, provide technical support, and ensure a smooth and hassle-free purchasing experience.

Choose us as your trusted supplier of Aluminum Coils in the Philippines and experience the difference of working with a reputable and reliable company. Contact us today to discuss your requirements and let us help you find the perfect Aluminum Coils solution for your projects.

In addition to our wide range of products, we also offer value-added services such as customization, fabrication, and logistics. Our team of experts can work closely with you to understand your specific requirements and provide tailored solutions that fit your needs. We have a strong network of suppliers and partners, enabling us to efficiently handle large-scale projects and meet tight deadlines.

At our company, we prioritize customer satisfaction and strive to exceed your expectations at every step. We are committed to building long-term relationships with our clients by offering reliable products, competitive prices, and exceptional service. Our dedicated team is always ready to assist you with any inquiries, provide technical support, and ensure a smooth and hassle-free purchasing experience.

Choose us as your trusted supplier of Aluminum Coils in the Philippines and experience the difference of working with a reputable and reliable company. Contact us today to discuss your requirements and let us help you find the perfect Aluminum Coils solution for your projects.