All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

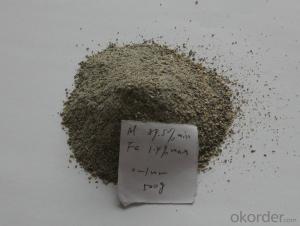

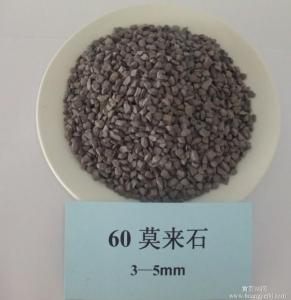

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Monolithic RefractoriesView More

Ceramic Fiber ProductsView More

Refractory BricksView More

Raw Materials For RefractoryView More

Q & A

What are the common refractory materials used in the steel industry?

The common refractory materials used in the steel industry include magnesite, dolomite, alumina, silica, and chromite. These materials have high melting points and excellent resistance to thermal shock, making them ideal for withstanding the extreme temperatures and aggressive chemical environments found in steelmaking processes.

What is the role of refractory materials in glass production?

Refractory materials play a crucial role in glass production as they are used to line the furnaces and other high-temperature areas of the glass-making process. These materials are designed to withstand extremely high temperatures and thermal shock, ensuring the longevity and efficiency of the furnaces. They also help in maintaining a stable temperature inside the furnace, preventing heat loss and reducing energy consumption. Additionally, refractory materials provide a protective barrier between the molten glass and the furnace, preventing contamination and ensuring the production of high-quality glass products.

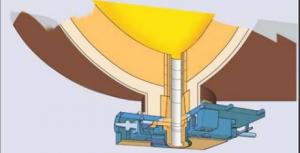

How do refractory materials affect the performance of gasifiers?

Refractory materials play a crucial role in the performance of gasifiers. They are used to line the walls of the gasifier chamber, where extreme temperatures and chemical reactions occur. The refractory materials need to withstand high temperatures and corrosive environments to ensure the gasifier's efficiency and longevity. They provide insulation, preventing heat loss and maintaining the desired temperature for efficient gasification. Additionally, refractories protect the gasifier walls from erosion caused by ash and slag, thereby extending the equipment's lifespan. Overall, the choice and quality of refractory materials significantly impact the performance and durability of gasifiers.

Wholesale Refractory Materials from supplier in Mauritania

Our team of professionals is dedicated to understanding your specific requirements and delivering the best solutions tailored to your needs. We offer a wide range of refractory materials, including bricks, castables, mortars, and insulation materials, suitable for various industries such as iron and steel, cement, glass, and petrochemical.

When you choose us as your supplier, you can expect:

1. High-Quality Products: We only source materials from trusted manufacturers to ensure the highest quality standards. Our products are designed to withstand extreme temperatures and harsh environments, ensuring optimal performance and longevity.

2. Competitive Pricing: As a subsidiary of CNBM, we have strong relationships with manufacturers, allowing us to offer competitive prices without compromising on quality. We aim to provide cost-effective solutions that meet your budget requirements.

3. Efficient Logistics: We have a well-established logistics network that enables us to deliver products to your desired location in a timely manner. Whether you require a small quantity or bulk orders, we can handle your requirements efficiently.

4. Technical Support: Our team of experts is available to provide technical advice and support throughout your project. We can assist with product selection, installation guidance, and troubleshooting, ensuring that you have the right materials and expertise to achieve optimal results.

5. Customer Satisfaction: We prioritize customer satisfaction and strive to exceed your expectations. Our dedicated customer service team is always ready to assist you with any inquiries or concerns you may have. We value long-term partnerships and aim to build trust and reliability with our clients.

Partner with us for all your refractory material needs in Mauritania, and experience a seamless procurement process backed by quality products, competitive pricing, and exceptional customer service. Contact us today for a quote or further information.

When you choose us as your supplier, you can expect:

1. High-Quality Products: We only source materials from trusted manufacturers to ensure the highest quality standards. Our products are designed to withstand extreme temperatures and harsh environments, ensuring optimal performance and longevity.

2. Competitive Pricing: As a subsidiary of CNBM, we have strong relationships with manufacturers, allowing us to offer competitive prices without compromising on quality. We aim to provide cost-effective solutions that meet your budget requirements.

3. Efficient Logistics: We have a well-established logistics network that enables us to deliver products to your desired location in a timely manner. Whether you require a small quantity or bulk orders, we can handle your requirements efficiently.

4. Technical Support: Our team of experts is available to provide technical advice and support throughout your project. We can assist with product selection, installation guidance, and troubleshooting, ensuring that you have the right materials and expertise to achieve optimal results.

5. Customer Satisfaction: We prioritize customer satisfaction and strive to exceed your expectations. Our dedicated customer service team is always ready to assist you with any inquiries or concerns you may have. We value long-term partnerships and aim to build trust and reliability with our clients.

Partner with us for all your refractory material needs in Mauritania, and experience a seamless procurement process backed by quality products, competitive pricing, and exceptional customer service. Contact us today for a quote or further information.

Hot Search

- Monolithic Refractories in Bangladesh

- Ceramic Fiber Products in Lebanon

- Refractory Bricks in Timor Leste

- Raw Materials For Refractory in Romania

- Monolithic Refractories in Panama

- Refractory Bricks in Algeria

- Refractory Bricks in Switzerland

- Raw Materials For Refractory in Austria

- Refractory Bricks in Spain

- Raw Materials For Refractory in Latvia