All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

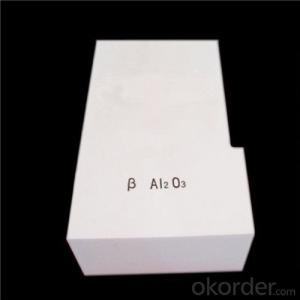

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

How do refractory bricks contribute to the longevity of equipment in high-temperature environments?

Refractory bricks contribute to the longevity of equipment in high-temperature environments by providing excellent thermal insulation and resistance to heat, corrosion, and mechanical stress. These bricks are specifically designed to withstand extreme temperatures and protect the underlying equipment from damage. They act as a barrier, preventing the heat from transferring to the equipment, thus reducing thermal stress and extending its lifespan. Additionally, refractory bricks also offer resistance against chemical reactions and erosion caused by harsh substances present in high-temperature environments, ensuring the durability and reliability of the equipment over time.

Are refractory bricks resistant to alkali attack?

Yes, refractory bricks are generally resistant to alkali attack. They are designed to withstand high temperatures and harsh chemical environments, including exposure to alkalis, making them suitable for various industrial applications such as furnaces, kilns, and incinerators.

Can refractory bricks be used in oil and gas industry?

Yes, refractory bricks can be used in the oil and gas industry. They are commonly used in high-temperature applications such as furnaces, boilers, and kilns, where they provide insulation and resistance to heat, chemicals, and mechanical stress. Refractory bricks help protect equipment and structures from the harsh conditions of the oil and gas industry, ensuring efficiency, safety, and longevity.

Can refractory bricks be used in heat recovery steam generators?

Yes, refractory bricks can be used in heat recovery steam generators. Refractory bricks are designed to withstand high temperatures and can be used to line the combustion chamber and other high-temperature areas in the steam generator, helping to contain and distribute heat efficiently.

What are the common refractory brick manufacturing methods?

The common refractory brick manufacturing methods include dry pressing, extrusion, and slip casting.

Wholesale Refractory Bricks from supplier in Timor Leste

Whether you are in need of standard refractory bricks or specialized refractory materials, we have you covered. Our range includes fire clay bricks, high alumina bricks, silica bricks, magnesia bricks, and more. We source our products from trusted manufacturers, ensuring top-notch quality and reliability.

In addition to supplying refractory bricks, we also provide sales and quoting services to assist you in finding the right products for your specific requirements. Our team of experts is always available to offer technical support and guidance, ensuring that you make informed decisions.

Being a subsidiary of CNBM, a Fortune Global 500 company, we have access to extensive resources and a global network. This allows us to offer competitive prices and efficient procurement solutions. We understand the unique challenges and requirements of the Timor Leste market, and our local presence ensures timely delivery and excellent customer service.

Our commitment to customer satisfaction extends beyond the sale. We offer after-sales support and maintenance services to ensure the long-lasting performance of our refractory bricks. Our goal is to build strong and lasting relationships with our customers by providing reliable products and exceptional service.

Whether you are in the steel, cement, glass, or any other industry requiring refractory bricks, we are here to fulfill your needs. Contact us today to discuss your requirements and let us be your trusted partner for all your refractory brick procurement needs in Timor Leste.

In addition to supplying refractory bricks, we also provide sales and quoting services to assist you in finding the right products for your specific requirements. Our team of experts is always available to offer technical support and guidance, ensuring that you make informed decisions.

Being a subsidiary of CNBM, a Fortune Global 500 company, we have access to extensive resources and a global network. This allows us to offer competitive prices and efficient procurement solutions. We understand the unique challenges and requirements of the Timor Leste market, and our local presence ensures timely delivery and excellent customer service.

Our commitment to customer satisfaction extends beyond the sale. We offer after-sales support and maintenance services to ensure the long-lasting performance of our refractory bricks. Our goal is to build strong and lasting relationships with our customers by providing reliable products and exceptional service.

Whether you are in the steel, cement, glass, or any other industry requiring refractory bricks, we are here to fulfill your needs. Contact us today to discuss your requirements and let us be your trusted partner for all your refractory brick procurement needs in Timor Leste.

Hot Search

- Monolithic Refractories in Uganda

- Ceramic Fiber Products in Zimbabwe

- Refractory Bricks in Mauritania

- Raw Materials For Refractory in Georgia

- Raw Materials For Refractory in Bulgaria

- Refractory Bricks in Thailand

- Refractory Bricks in Austria

- Monolithic Refractories in Poland

- Monolithic Refractories in Nigeria

- Ceramic Fiber Products in Japan