All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

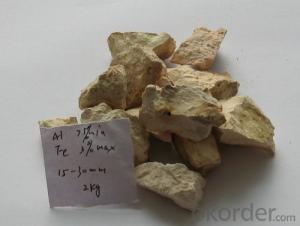

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

Can you explain the concept of slag resistance in refractories?

Slag resistance in refractories refers to the ability of a material to withstand the corrosive effects of molten slags. Refractories are often used in industries such as steelmaking, where they come into contact with high-temperature molten slags that can chemically attack and erode the refractory lining. Slag resistance is essential for maintaining the integrity and longevity of the refractory material. It depends on factors like the chemical composition of the refractory, its porosity, and the presence of certain additives. Refractories with high slag resistance are able to form a protective layer or react with the slag, preventing it from penetrating the refractory and causing damage.

How is perlite obtained and processed for refractory use?

Perlite is obtained through mining, where it is extracted from volcanic rocks. The rocks are crushed and then heated at extremely high temperatures, causing the perlite to expand and form its characteristic lightweight and porous structure. After expansion, the perlite is further processed to remove any impurities and then classified into different grades based on particle size. In refractory applications, perlite is often mixed with binders and additives to enhance its thermal and mechanical properties, and then shaped into desired forms such as bricks or boards before being used in high-temperature environments.

What are the refractory raw materials used in lining reheating furnaces?

The refractory raw materials commonly used in lining reheating furnaces are high-alumina bricks, fireclay bricks, silica bricks, and insulating materials like ceramic fiber blankets. These materials are chosen for their high heat resistance and ability to withstand the extreme temperatures and thermal cycling experienced in reheating furnaces.

Wholesale Raw Materials For Refractory from supplier in Japan

With our expertise in supplying Raw Materials For Refractory, we strive to meet the specific needs of our customers in Japan. Our dedicated team is committed to providing excellent sales, quotation, and technical support services to ensure a smooth and efficient procurement process.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the resources and capabilities to offer comprehensive solutions for Raw Materials For Refractory in Japan. We understand the importance of reliable and high-quality materials for refractory applications, and we work closely with our customers to provide the best products for their projects.

Our extensive product range covers a wide variety of Raw Materials For Refractory, ensuring that you will find everything you need for your refractory applications. Whether you require refractory bricks, castables, or other refractory materials, we have you covered.

With years of experience in the Japanese market, we have gained valuable insights and knowledge that can benefit your projects. We understand the local regulations, industry standards, and market trends, allowing us to provide tailored solutions that meet your specific requirements.

Furthermore, we are excited to introduce you to the unique characteristics and offerings of Japan. Known for its rich culture, advanced technology, and exquisite landscapes, Japan offers a wealth of opportunities for businesses and individuals alike. We are here to support you in exploring and harnessing the potential that Japan has to offer.

So whether you are in need of Raw Materials For Refractory or looking to tap into the Japanese market, we are here to assist you every step of the way. Contact us today to learn more about our products and services, and let us contribute to the success of your projects in Japan.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the resources and capabilities to offer comprehensive solutions for Raw Materials For Refractory in Japan. We understand the importance of reliable and high-quality materials for refractory applications, and we work closely with our customers to provide the best products for their projects.

Our extensive product range covers a wide variety of Raw Materials For Refractory, ensuring that you will find everything you need for your refractory applications. Whether you require refractory bricks, castables, or other refractory materials, we have you covered.

With years of experience in the Japanese market, we have gained valuable insights and knowledge that can benefit your projects. We understand the local regulations, industry standards, and market trends, allowing us to provide tailored solutions that meet your specific requirements.

Furthermore, we are excited to introduce you to the unique characteristics and offerings of Japan. Known for its rich culture, advanced technology, and exquisite landscapes, Japan offers a wealth of opportunities for businesses and individuals alike. We are here to support you in exploring and harnessing the potential that Japan has to offer.

So whether you are in need of Raw Materials For Refractory or looking to tap into the Japanese market, we are here to assist you every step of the way. Contact us today to learn more about our products and services, and let us contribute to the success of your projects in Japan.

Hot Search

- Monolithic Refractories in Lebanon

- Ceramic Fiber Products in Liberia

- Refractory Bricks in Sri Lanka

- Raw Materials For Refractory in Madagascar

- Monolithic Refractories in Ecuador

- Refractory Bricks in Netherlands

- Raw Materials For Refractory in Kazakhstan

- Ceramic Fiber Products in Spain

- Refractory Bricks in Andorra

- Raw Materials For Refractory in United Arab Emirates