All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

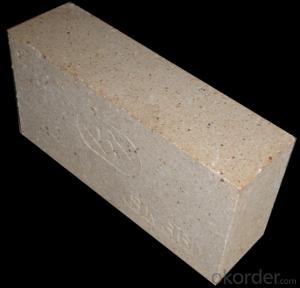

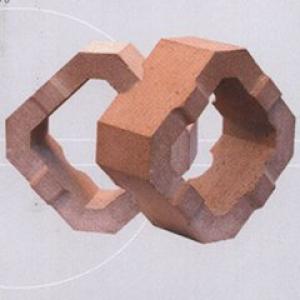

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

How do refractory bricks affect the overall efficiency of a furnace?

Refractory bricks play a crucial role in improving the overall efficiency of a furnace. These bricks are designed to withstand high temperatures and provide insulation, preventing heat loss from the furnace. By maintaining a consistent temperature within the furnace, refractory bricks minimize energy wastage and improve fuel efficiency. Additionally, they help protect the furnace lining from corrosion and wear, ensuring longer operational life and reducing maintenance costs.

Can refractory bricks be used in high-pressure environments?

Yes, refractory bricks can be used in high-pressure environments. Refractory bricks are designed to withstand extreme temperatures and provide excellent thermal insulation. They are commonly used in high-pressure applications such as boilers, furnaces, and industrial kilns, where they can maintain their structural integrity and resistance to pressure.

Can refractory bricks be used in ceramic industry?

Yes, refractory bricks can be used in the ceramic industry. Refractory bricks are specifically designed to withstand high temperatures and provide insulation, making them suitable for various applications in the ceramic industry such as kilns, furnaces, and other thermal processes.

How do refractory bricks resist sulfur attack?

Refractory bricks resist sulfur attack by having a high melting point and chemical composition that is resistant to sulfur compounds. They are designed to withstand high temperatures and the corrosive effects of sulfur, preventing it from penetrating or reacting with the brick material.

Can refractory bricks be used in the construction of boilers for textile manufacturing?

Yes, refractory bricks can be used in the construction of boilers for textile manufacturing. Refractory bricks are known for their ability to withstand high temperatures and provide insulation, making them suitable for use in boilers where heat is generated during the textile manufacturing process.

Wholesale Refractory Bricks from supplier in Gabon

We understand the importance of reliable and high-quality products in the refractory industry. That is why we source our refractory bricks from trusted manufacturers who adhere to strict quality control standards. Our comprehensive range of refractory bricks includes fire clay bricks, high alumina bricks, silica bricks, and magnesia bricks, among others.

Our sales team is knowledgeable and experienced, and they are committed to understanding your specific requirements and providing you with the best solution. We offer competitive prices and prompt delivery to ensure that your projects stay on schedule. Furthermore, our technical support team is available to answer any questions and provide guidance throughout the installation and maintenance processes.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and expertise. This allows us to offer you a one-stop solution for all your refractory bricks needs in Gabon. Whether you need assistance with product selection, technical specifications, or after-sales support, we have the capabilities to meet your needs.

We have built strong relationships with clients in various industries, including steel, cement, glass, and power generation. Our extensive experience in the Gabon market has given us valuable insights into the unique challenges and requirements of the local industry. We are committed to providing tailored solutions that address your specific needs and help you achieve success in your projects.

Customer satisfaction is our top priority, and we take pride in delivering exceptional products and services. We believe in building long-term partnerships with our clients, and we are dedicated to meeting and exceeding your expectations. Choose us as your refractory bricks supplier in Gabon, and let us be your trusted partner in success. Contact us today to discuss your requirements and how we can assist you.

Our sales team is knowledgeable and experienced, and they are committed to understanding your specific requirements and providing you with the best solution. We offer competitive prices and prompt delivery to ensure that your projects stay on schedule. Furthermore, our technical support team is available to answer any questions and provide guidance throughout the installation and maintenance processes.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and expertise. This allows us to offer you a one-stop solution for all your refractory bricks needs in Gabon. Whether you need assistance with product selection, technical specifications, or after-sales support, we have the capabilities to meet your needs.

We have built strong relationships with clients in various industries, including steel, cement, glass, and power generation. Our extensive experience in the Gabon market has given us valuable insights into the unique challenges and requirements of the local industry. We are committed to providing tailored solutions that address your specific needs and help you achieve success in your projects.

Customer satisfaction is our top priority, and we take pride in delivering exceptional products and services. We believe in building long-term partnerships with our clients, and we are dedicated to meeting and exceeding your expectations. Choose us as your refractory bricks supplier in Gabon, and let us be your trusted partner in success. Contact us today to discuss your requirements and how we can assist you.

Hot Search

- Monolithic Refractories in Uruguay

- Ceramic Fiber Products in Chile

- Refractory Bricks in Peru

- Raw Materials For Refractory in Honduras

- Ceramic Fiber Products in Seychelles

- Ceramic Fiber Products in Burundi

- Refractory Bricks in Bolivia

- Monolithic Refractories in Barbados

- Refractory Bricks in Colombia

- Monolithic Refractories in Croatia