All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Aluminum StripsView More

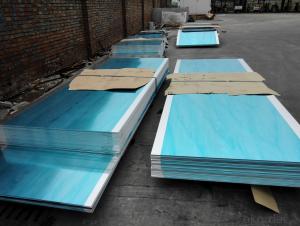

Aluminum SheetsView More

Aluminum CoilsView More

Aluminum FoilsView More

Aluminum ProfilesView More

Q & A

How is aluminum material welded?

Aluminum material is commonly welded using various methods such as gas tungsten arc welding (GTAW), also known as TIG welding, and gas metal arc welding (GMAW), also known as MIG welding. These processes involve melting the aluminum pieces together using a filler material and an electric arc. Additionally, friction stir welding (FSW) is another technique used for joining aluminum where a rotating tool generates friction and heat, resulting in a solid-state weld. Overall, the welding process depends on the specific application and desired outcome.

What is the environmental impact of aluminum products?

The environmental impact of aluminum products is significant. The extraction of aluminum from bauxite ore requires a large amount of energy, contributing to greenhouse gas emissions and air pollution. Additionally, the production process generates toxic waste called red mud, which can pollute nearby ecosystems if not properly managed. Aluminum products are also often single-use, leading to waste generation and increased demand for raw materials. However, aluminum is highly recyclable, which helps mitigate its environmental impact by reducing energy consumption and emissions associated with extraction and production.

What are the differences between wrought aluminum and cast aluminum?

Wrought aluminum and cast aluminum differ in their production methods and resulting properties. Wrought aluminum is manufactured by shaping and compressing the metal while it is in a solid state, resulting in a more refined and uniform structure. In contrast, cast aluminum is produced by melting the metal and pouring it into a mold to solidify, which can result in a coarser and less uniform structure. Wrought aluminum tends to have better mechanical properties such as higher strength and durability, while cast aluminum is usually more cost-effective and easier to produce complex shapes. Overall, the choice between wrought and cast aluminum depends on the specific application and desired properties.

Wholesale Aluminum from supplier in Gabon

Our team of dedicated professionals understands the specific needs and requirements of the Gabonese market, and we work closely with our customers to deliver customized solutions. Whether you need aluminum sheets, plates, profiles, or any other aluminum products, we have a wide range of options to meet your needs.

In addition to our extensive inventory, we also offer competitive pricing and flexible delivery options to ensure that your projects stay on schedule and within budget. Our technical support team is available to provide guidance and assistance throughout the procurement process, helping you make informed decisions and achieve optimal results.

Furthermore, as a subsidiary of CNBM, we benefit from the global resources and expertise of a Fortune Global 500 company. This allows us to leverage our industry knowledge and network to source high-quality aluminum products at competitive prices.

We believe in building long-term partnerships with our clients, and our commitment to customer satisfaction is at the forefront of everything we do. We strive to exceed your expectations by providing exceptional service, reliable products, and timely support.

Contact us today to discuss your aluminum procurement needs in Gabon, and let us help you find the perfect solution for your projects.

In addition to our extensive inventory, we also offer competitive pricing and flexible delivery options to ensure that your projects stay on schedule and within budget. Our technical support team is available to provide guidance and assistance throughout the procurement process, helping you make informed decisions and achieve optimal results.

Furthermore, as a subsidiary of CNBM, we benefit from the global resources and expertise of a Fortune Global 500 company. This allows us to leverage our industry knowledge and network to source high-quality aluminum products at competitive prices.

We believe in building long-term partnerships with our clients, and our commitment to customer satisfaction is at the forefront of everything we do. We strive to exceed your expectations by providing exceptional service, reliable products, and timely support.

Contact us today to discuss your aluminum procurement needs in Gabon, and let us help you find the perfect solution for your projects.