All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

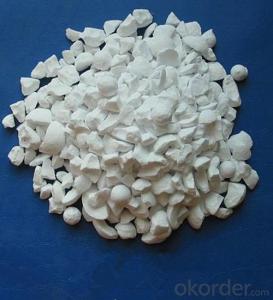

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

How do refractories perform under reducing atmospheres in industrial processes?

Refractories generally perform well under reducing atmospheres in industrial processes. This is because refractories are designed to withstand high temperatures, chemical reactions, and thermal shocks. In reducing atmospheres, where oxygen levels are low, refractories are less prone to oxidation and degradation. However, they may still be susceptible to certain chemical reactions and may require careful selection and design to ensure optimal performance in these conditions.

What are the advantages of using fused magnesia as a raw material in refractory production?

Fused magnesia offers several advantages as a raw material in refractory production. Firstly, its high refractoriness and excellent thermal stability make it suitable for applications in high-temperature environments. Additionally, fused magnesia has a low coefficient of thermal expansion, which helps to reduce the risk of cracking and spalling under extreme thermal conditions. Its high density and strength contribute to the durability and longevity of the refractory products. Fused magnesia also exhibits good resistance to chemical attack, ensuring its suitability for various corrosive and aggressive environments. Lastly, its consistent and controlled composition allows for precise formulation and customization of refractory products to meet specific requirements.

How do raw materials contribute to the abrasion resistance of refractory products?

Raw materials play a crucial role in enhancing the abrasion resistance of refractory products. By selecting and incorporating appropriate raw materials, such as high-density aggregates, binders, and additives, the resulting refractory product gains improved strength, hardness, and resistance to wear and tear caused by friction and contact with abrasive materials. The raw materials used in refractory production provide the necessary properties to withstand harsh environments, prolonging the lifespan and performance of the refractory products in various industrial applications.

Can you explain the role of rutile in refractories?

Rutile is a mineral that plays a crucial role in refractories. It acts as a fluxing agent, improving the flow properties of the refractory material during its manufacturing process. Rutile also helps in reducing the firing temperature required for the refractory, enhancing its overall strength and durability. Additionally, rutile contributes to the formation of a stable microstructure within the refractory, improving its resistance to thermal and mechanical stress. In summary, rutile plays a significant role in enhancing the performance and quality of refractories.

Wholesale Raw Materials For Refractory from supplier in Estonia

We understand the importance of high-quality raw materials in the production of refractory products. That is why we source our materials from trusted suppliers and ensure that they meet the required specifications and standards.

Our sales team is dedicated to assisting customers in Estonia with their procurement needs. We provide timely and competitive quotations, ensuring that you get the best value for your investment. Additionally, our technical support team is available to answer any questions and provide guidance throughout the process.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and expertise. This enables us to offer a wide range of raw materials for refractory products, including but not limited to minerals, binders, and additives. Our diverse product portfolio ensures that you can find the right materials for your specific requirements.

Furthermore, our extensive market experience in Estonia allows us to understand the local industry trends and requirements. We can provide valuable insights and support for your projects, helping you make informed decisions and achieve optimal results.

In summary, as a dedicated supplier of raw materials for refractory products in Estonia, our company offers comprehensive services, competitive pricing, and technical support. We strive to be your trusted partner in fulfilling your procurement needs and supporting your projects.

Our sales team is dedicated to assisting customers in Estonia with their procurement needs. We provide timely and competitive quotations, ensuring that you get the best value for your investment. Additionally, our technical support team is available to answer any questions and provide guidance throughout the process.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and expertise. This enables us to offer a wide range of raw materials for refractory products, including but not limited to minerals, binders, and additives. Our diverse product portfolio ensures that you can find the right materials for your specific requirements.

Furthermore, our extensive market experience in Estonia allows us to understand the local industry trends and requirements. We can provide valuable insights and support for your projects, helping you make informed decisions and achieve optimal results.

In summary, as a dedicated supplier of raw materials for refractory products in Estonia, our company offers comprehensive services, competitive pricing, and technical support. We strive to be your trusted partner in fulfilling your procurement needs and supporting your projects.

Hot Search

- Monolithic Refractories in Namibia

- Ceramic Fiber Products in Turkey

- Refractory Bricks in Hungary

- Raw Materials For Refractory in Panama

- Monolithic Refractories in Guinea

- Refractory Bricks in Zambia

- Raw Materials For Refractory in Austria

- Raw Materials For Refractory in Monaco

- Raw Materials For Refractory in Colombia

- Refractory Bricks in Indonesia