All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

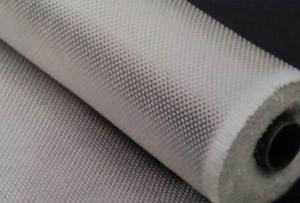

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Fiberglass Chopped StrandView More

Fiberglass Mesh ClothView More

Composite PipesView More

FRP Pultrusion ProfilesView More

Fiberglass Mat TissueView More

Fiberglass FabricsView More

Fiberglass MeshView More

Composite TankView More

Fiberglass Mesh tapeView More

PolymerView More

FRP Roofing PanelView More

Fiberglass RovingView More

Q & A

How does the dimensional stability of fiberglass compare to other materials?

Fiberglass generally exhibits excellent dimensional stability when compared to other materials. Its low coefficient of thermal expansion combined with its high strength-to-weight ratio make it highly resistant to warping, shrinking, or expanding due to temperature changes or moisture absorption. This dimensional stability is one of the key reasons why fiberglass is widely used in various industries such as construction, aerospace, automotive, and marine.

How do you repair fiberglass components in electrical equipment?

To repair fiberglass components in electrical equipment, first, ensure the equipment is powered off and disconnected. Clean the damaged area thoroughly and remove any loose or damaged fiberglass material. Next, apply a layer of fiberglass resin or epoxy to the damaged area, ensuring it is evenly spread and covers the entire surface. Place a piece of fiberglass cloth or mat over the resin, making sure it overlaps the damaged area. Apply another layer of resin over the cloth/mat, ensuring it is saturated and smooth. Allow the resin to cure according to the manufacturer's instructions. Finally, sand the repaired area to smoothen it, and apply a coat of paint or protective finish, if necessary.

How is fiberglass used in the production of bathtubs and showers?

Fiberglass is commonly used in the production of bathtubs and showers as it provides a lightweight yet durable material. It is typically used as a reinforcement for the structure of the tub or shower, making it strong and resistant to cracking or breaking. Fiberglass also allows for various shapes and designs, enabling manufacturers to create unique and stylish products. Additionally, its smooth surface makes it easy to clean and maintain, making fiberglass an ideal choice for bathtubs and showers.

What are the different thickness options available for fiberglass supply insulation?

The different thickness options available for fiberglass supply insulation typically range from 1 inch to 12 inches, allowing for various levels of thermal resistance and energy efficiency.

Wholesale Fiberglass Supply from supplier in Dominican

Whether you are in need of fiberglass materials for construction, marine applications, or industrial purposes, we have the expertise and resources to meet your requirements. Our team of professionals is dedicated to providing excellent customer service and ensuring that you receive the highest quality products at competitive prices.

In addition to our wide range of fiberglass products, we also offer comprehensive technical support services. Our knowledgeable staff can assist you with product selection, installation guidance, and troubleshooting, ensuring that your project runs smoothly from start to finish.

As a subsidiary of CNBM, we benefit from the resources and global network of one of the world's largest building materials companies. This allows us to offer competitive pricing, reliable supply chain management, and access to the latest innovations in fiberglass technology.

We understand the unique challenges and requirements of the Dominican Republic market and have tailored our offerings to meet the specific needs of our customers in this region. Whether you are a contractor, distributor, or end-user, we are committed to providing you with the best solutions for your fiberglass supply needs.

Contact us today to discuss your requirements and discover how our Fiberglass Supply products and services can benefit your projects in the Dominican Republic.

In addition to our wide range of fiberglass products, we also offer comprehensive technical support services. Our knowledgeable staff can assist you with product selection, installation guidance, and troubleshooting, ensuring that your project runs smoothly from start to finish.

As a subsidiary of CNBM, we benefit from the resources and global network of one of the world's largest building materials companies. This allows us to offer competitive pricing, reliable supply chain management, and access to the latest innovations in fiberglass technology.

We understand the unique challenges and requirements of the Dominican Republic market and have tailored our offerings to meet the specific needs of our customers in this region. Whether you are a contractor, distributor, or end-user, we are committed to providing you with the best solutions for your fiberglass supply needs.

Contact us today to discuss your requirements and discover how our Fiberglass Supply products and services can benefit your projects in the Dominican Republic.

Hot Search

- Fiberglass Chopped Strand in Finland

- Fiberglass Mesh Cloth in Sri Lanka

- Composite Pipes in Paraguay

- FRP Pultrusion Profiles in Dominica

- Fiberglass Mat Tissue in Albania

- Fiberglass Fabrics in Israel

- Fiberglass Mesh in Malaysia

- Composite Tank in Comoros

- Fiberglass Mesh tape in Tunisia

- Polymer in Croatia