All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

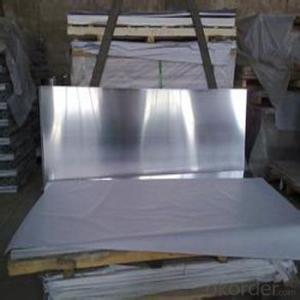

How are the mechanical properties of aluminum coils tested and verified?

The mechanical properties of aluminum coils are tested and verified through various methods including tensile testing, hardness testing, impact testing, and fatigue testing. These tests are conducted to measure parameters such as yield strength, ultimate tensile strength, elongation, hardness, impact resistance, and fatigue strength. Additionally, other tests like bend testing, creep testing, and microstructure analysis may also be performed to assess the quality and performance of aluminum coils.

What is the role of aluminum coils in the manufacturing of aluminum signage for advertising?

The role of aluminum coils in the manufacturing of aluminum signage for advertising is to provide a durable and versatile material for constructing the signage. Aluminum coils are used as the primary material for creating the body of the signage, allowing for easy shaping, cutting, and forming to achieve various designs and sizes. The coils are processed and treated to enhance their strength, corrosion resistance, and weatherability, ensuring the longevity and effectiveness of the signage in outdoor advertising applications.

How are aluminum coils used in the HVAC ductwork industry?

Aluminum coils are commonly used in the HVAC ductwork industry for their lightweight, corrosion-resistant properties. They are typically used in the fabrication of air conditioning and heating systems, where they help facilitate the transfer of heat and maintain desired temperatures within a building. The coils are shaped into various configurations and sizes to fit different HVAC system designs, ensuring efficient airflow and heat exchange throughout the ductwork.

Can aluminum coils be used in the production of aluminum cans for beverages?

Yes, aluminum coils can be used in the production of aluminum cans for beverages. The coils are typically processed and shaped into flat sheets, which are then cut, printed, and formed into the familiar cylindrical shape of beverage cans.

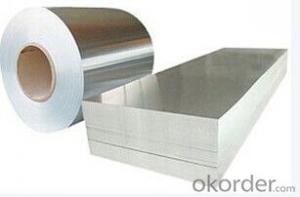

Wholesale Aluminum Coils from supplier in Dominican

Our team of experts is dedicated to ensuring that you receive the highest quality Aluminum Coils that meet your specific requirements. We offer a wide range of sizes, grades, and finishes to suit various applications in the Dominican Republic.

In addition to supplying Aluminum Coils, we also provide value-added services such as cutting, slitting, and packaging to meet your exact specifications. We understand the importance of timely delivery, and our efficient logistics network ensures that your orders are delivered on time and in perfect condition.

Furthermore, our technical team is always available to provide assistance and guidance throughout your project. Whether you need help with product selection, design optimization, or troubleshooting, we are here to support you every step of the way.

At CNBM, we prioritize customer satisfaction and strive to build long-term partnerships based on trust and reliability. Our commitment to quality, competitive pricing, and excellent customer service sets us apart from other suppliers in the industry.

Contact us today to discuss your Aluminum Coils requirements in the Dominican Republic and discover how we can assist you in achieving your project goals.

In addition to supplying Aluminum Coils, we also provide value-added services such as cutting, slitting, and packaging to meet your exact specifications. We understand the importance of timely delivery, and our efficient logistics network ensures that your orders are delivered on time and in perfect condition.

Furthermore, our technical team is always available to provide assistance and guidance throughout your project. Whether you need help with product selection, design optimization, or troubleshooting, we are here to support you every step of the way.

At CNBM, we prioritize customer satisfaction and strive to build long-term partnerships based on trust and reliability. Our commitment to quality, competitive pricing, and excellent customer service sets us apart from other suppliers in the industry.

Contact us today to discuss your Aluminum Coils requirements in the Dominican Republic and discover how we can assist you in achieving your project goals.