All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How do you troubleshoot common issues in the production of aluminum coils?

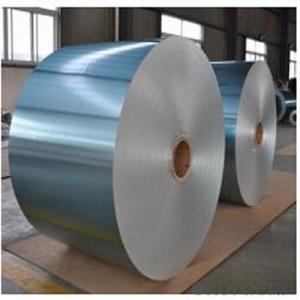

To troubleshoot common issues in the production of aluminum coils, you can follow a systematic approach. Firstly, analyze the specific problem and gather relevant data such as coil thickness, temperature, speed, and chemical composition. Then, review the production process to identify any deviations or abnormalities. Next, inspect the equipment and machinery for any malfunctions or wear and tear that may be causing the issue. Additionally, assess the quality of raw materials and ensure they meet the required specifications. Conducting tests and measurements at various stages of production can help pinpoint the root cause of the problem. Finally, collaborate with the production team and experts to develop and implement corrective actions to resolve the issue and prevent future occurrences.

How do you calculate the expansion coefficient of aluminum coils for temperature changes?

To calculate the expansion coefficient of aluminum coils for temperature changes, you need to measure the change in length of the coil as the temperature changes. Divide this change in length by the original length of the coil and the temperature change to obtain the expansion coefficient.

What is the role of aluminum coils in the manufacturing of storage tanks?

The role of aluminum coils in the manufacturing of storage tanks is to provide a strong and durable material for constructing the tank's walls. Aluminum coils are lightweight, corrosion-resistant, and have high strength-to-weight ratio, making them ideal for storing various substances such as water, chemicals, or gases. These coils are formed and welded together to create a seamless tank structure that can withstand the pressure and environmental conditions required for storage purposes.

Can aluminum coils be used for aerospace structural components?

Yes, aluminum coils can be used for aerospace structural components. Aluminum is a lightweight and strong material that has been widely used in the aerospace industry for various applications including structural components. Its high strength-to-weight ratio, corrosion resistance, and ability to withstand extreme temperatures make it suitable for use in aircraft structures. Aluminum coils can be formed and shaped into desired configurations, providing flexibility and ease of manufacturing for aerospace structural components.

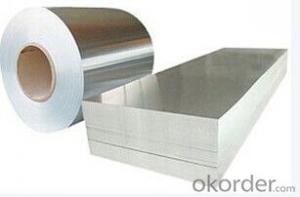

Wholesale Aluminum Coils from supplier in Croatia

We are confident that our expertise and dedication to customer satisfaction will make us the preferred choice for all your Aluminum Coils needs in Croatia. Contact us today to learn more about our products and services and how we can support your projects.