All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

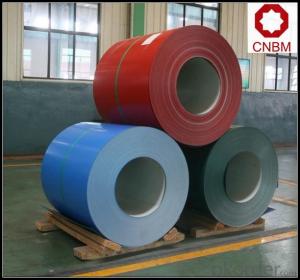

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the methods for adjusting the width and thickness of aluminum coils during processing?

There are several methods for adjusting the width and thickness of aluminum coils during processing. One common method is called roll forming, where the coil is passed through a series of rollers that gradually shape and compress the metal to achieve the desired width and thickness. Another method is called slitting, where the coil is cut into narrower strips using a rotating circular blade. Additionally, the coil can be stretched or annealed to alter its dimensions.

What are the applications of aluminum coils in the production of aluminum beverage can bodies?

Aluminum coils are widely used in the production of aluminum beverage can bodies due to their versatility and advantageous properties. These coils serve several applications, including forming the can bodies, providing strength and durability, ensuring a smooth surface finish, and facilitating the printing process for branding and labeling. Additionally, aluminum coils are lightweight, corrosion-resistant, and can be easily recycled, making them an ideal choice for the sustainable production of beverage cans.

How are aluminum coils used in the production of aerospace structures?

Aluminum coils are commonly used in the production of aerospace structures due to their lightweight and high strength properties. These coils are typically processed into sheets or plates, which are then formed, cut, and assembled to create various components of an aircraft, such as fuselage panels, wing skins, and structural supports. The use of aluminum coils allows for greater fuel efficiency, improved maneuverability, and overall weight reduction, making them an essential material in aerospace manufacturing.

What are the quality control measures for aluminum coil surface finish?

Some quality control measures for aluminum coil surface finish include visual inspection for scratches, dents, or other defects, measuring the thickness of the coating using a coating thickness gauge, conducting adhesion tests to ensure the coating adheres properly to the surface, performing color tests to check for consistency and uniformity, and conducting corrosion resistance tests to assess the durability of the surface finish.

Wholesale Aluminum Coils from supplier in Kenya

Whether you are in the construction, automotive, or manufacturing industry, we have the right Aluminum Coils products to meet your specific requirements. Our Aluminum Coils are sourced from reputable manufacturers and are available in various sizes, thicknesses, and finishes to cater to diverse applications.

We understand the importance of timely delivery and strive to ensure that our customers receive their orders on time. Our dedicated team of professionals is committed to providing excellent customer service, assisting you with any inquiries, and offering technical support whenever needed.

In addition to supplying Aluminum Coils, we also provide value-added services such as cutting, slitting, and packaging, to ensure that the products are tailored to your exact specifications. We also offer competitive pricing to help you maximize your budget and achieve cost-effective solutions.

At CNBM Kenya, we prioritize quality and reliability. Our Aluminum Coils undergo strict quality control measures to ensure that they meet international standards and provide optimal performance. We are confident in the durability and longevity of our products, allowing you to have peace of mind knowing that you are investing in high-quality materials.

No matter the size or complexity of your project, we are here to support you every step of the way. Contact us today to discuss your Aluminum Coils requirements and let us help you find the best solutions for your business in Kenya.

We understand the importance of timely delivery and strive to ensure that our customers receive their orders on time. Our dedicated team of professionals is committed to providing excellent customer service, assisting you with any inquiries, and offering technical support whenever needed.

In addition to supplying Aluminum Coils, we also provide value-added services such as cutting, slitting, and packaging, to ensure that the products are tailored to your exact specifications. We also offer competitive pricing to help you maximize your budget and achieve cost-effective solutions.

At CNBM Kenya, we prioritize quality and reliability. Our Aluminum Coils undergo strict quality control measures to ensure that they meet international standards and provide optimal performance. We are confident in the durability and longevity of our products, allowing you to have peace of mind knowing that you are investing in high-quality materials.

No matter the size or complexity of your project, we are here to support you every step of the way. Contact us today to discuss your Aluminum Coils requirements and let us help you find the best solutions for your business in Kenya.