All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

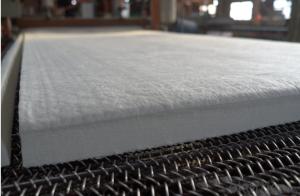

- - Ceramic Fiber Products

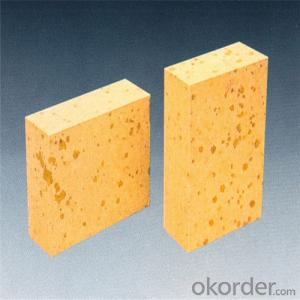

- - Refractory Bricks

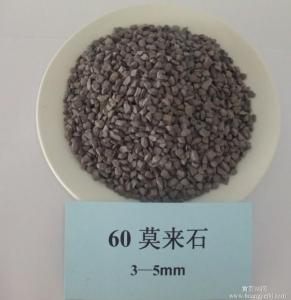

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Monolithic RefractoriesView More

Ceramic Fiber ProductsView More

Refractory BricksView More

Raw Materials For RefractoryView More

Q & A

What are the main raw materials used in refractory manufacturing?

The main raw materials used in refractory manufacturing include clay, silica, alumina, magnesia, and various additives such as binders, fluxes, and stabilizers.

What are the advantages of using refractory coatings for thermal cycling resistance?

Refractory coatings offer several advantages for thermal cycling resistance. Firstly, they provide a protective barrier against high temperatures and thermal shocks, preventing damage to the underlying substrate. Secondly, these coatings improve the overall thermal insulation of the material, reducing heat loss and promoting energy efficiency. Additionally, they can enhance the material's resistance to corrosion, oxidation, and other chemical reactions, prolonging its lifespan in harsh environments. Lastly, refractory coatings allow for easier maintenance and repair, as they can be easily applied and reapplied, saving time and resources in the long run.

What are the properties of dense refractory castables?

Dense refractory castables have high density and low porosity, which give them excellent strength and abrasion resistance. They also have high thermal conductivity and can withstand high temperatures without significant thermal expansion or cracking. Additionally, they possess good chemical resistance and are capable of withstanding harsh environments and corrosive substances.

Wholesale Refractory Materials from supplier in British

Note: This response has been generated by OpenAI's GPT-3 model, a language model trained to generate human-like text. While it strives to provide accurate and helpful information, it should not be taken as a factual statement. Please consult with a professional or conduct further research before making any business decisions.

Hot Search

- Monolithic Refractories in Rwanda

- Ceramic Fiber Products in Cameroon

- Refractory Bricks in Luxembourg

- Raw Materials For Refractory in Niue

- Refractory Bricks in Malaysia

- Raw Materials For Refractory in Kuwait

- Ceramic Fiber Products in Vietnam

- Refractory Bricks in Tanzania

- Raw Materials For Refractory in Canada

- Monolithic Refractories in Maldives