All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How do you protect aluminum coils from galvanic corrosion when in contact with other metals?

To protect aluminum coils from galvanic corrosion when in contact with other metals, several measures can be taken. One common approach is to apply a protective coating or paint on the aluminum surface. This creates a barrier between the aluminum and the other metal, preventing direct contact and minimizing the risk of galvanic corrosion. Another method is to use isolation materials such as gaskets or insulating tape to separate the aluminum coils from the contacting metals. Additionally, ensuring proper ventilation and controlling humidity levels in the environment can help reduce the likelihood of corrosion. Regular inspections and maintenance are also crucial to identify any potential corrosion issues early on and take appropriate measures to prevent further damage.

What is the role of aluminum coils in the manufacturing of consumer electronics?

The role of aluminum coils in the manufacturing of consumer electronics is primarily to dissipate heat generated by the electronic components, ensuring efficient operation and preventing overheating. Aluminum coils are commonly used in devices such as laptops, smartphones, and televisions to help maintain optimal temperature levels and enhance the overall performance and durability of the devices.

What are the steps involved in coil blanking for aluminum coils?

Coil blanking for aluminum coils involves several steps. First, the aluminum coils are loaded onto a decoiler, which unwinds the coil and feeds it into the blanking line. Then, the coil is leveled to ensure a flat surface. Next, the coil is fed into a straightener, which removes any remaining curvature. After that, the coil is transferred to a feeder, which moves the coil forward at a consistent speed. The coil then enters a blanking press, where it is cut into individual blanks according to the desired size and shape. Finally, the blanks are collected and packaged for further processing or shipment.

What are the various grades of aluminum used in coil production?

The various grades of aluminum commonly used in coil production include 1100, 3003, 3004, 5052, and 6061.

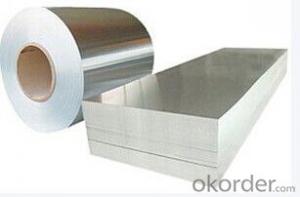

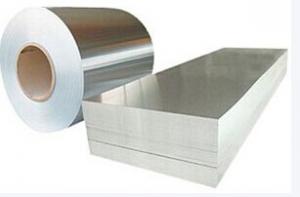

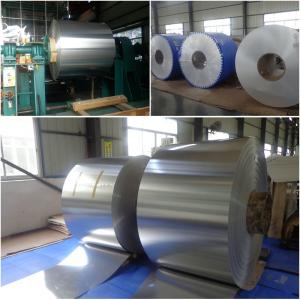

Wholesale Aluminum Coils from supplier in British

Whether you need Aluminum Coils for construction, transportation, packaging, or any other application, we are here to meet your specific requirements. Our team of experts is dedicated to providing you with personalized solutions and guiding you through the entire procurement process.

As a trusted supplier, we adhere to strict quality control measures to ensure that our Aluminum Coils meet the highest industry standards. Our products are sourced from reliable manufacturers and undergo rigorous testing to guarantee their durability, strength, and performance.

In addition to supplying Aluminum Coils, we also offer value-added services such as customization, cutting, and finishing. Our technical support team is available to assist you with any questions or concerns you may have, ensuring a smooth and successful project execution.

At our company, we understand the importance of timely delivery and competitive pricing. We work closely with our logistic partners to ensure prompt and efficient delivery of your Aluminum Coils, saving you time and money.

Contact us today to discuss your Aluminum Coils requirements and discover how we can add value to your projects. We are committed to providing you with top-notch products, exceptional service, and competitive prices. Trust us as your reliable partner in the British Aluminum Coils market.

As a trusted supplier, we adhere to strict quality control measures to ensure that our Aluminum Coils meet the highest industry standards. Our products are sourced from reliable manufacturers and undergo rigorous testing to guarantee their durability, strength, and performance.

In addition to supplying Aluminum Coils, we also offer value-added services such as customization, cutting, and finishing. Our technical support team is available to assist you with any questions or concerns you may have, ensuring a smooth and successful project execution.

At our company, we understand the importance of timely delivery and competitive pricing. We work closely with our logistic partners to ensure prompt and efficient delivery of your Aluminum Coils, saving you time and money.

Contact us today to discuss your Aluminum Coils requirements and discover how we can add value to your projects. We are committed to providing you with top-notch products, exceptional service, and competitive prices. Trust us as your reliable partner in the British Aluminum Coils market.