All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

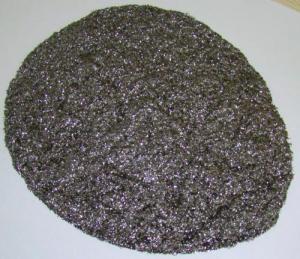

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

How are alumina-chrome refractories used in the petrochemical industry?

Alumina-chrome refractories are widely used in the petrochemical industry due to their excellent high-temperature resistance and chemical stability. These refractories are primarily used to line and protect various high-temperature equipment such as furnaces, reactors, and kilns in petrochemical plants. They act as a barrier, preventing heat transfer and chemical reactions that could compromise the integrity of the equipment. Additionally, alumina-chrome refractories are also resistant to thermal shock, making them suitable for the rapid temperature changes often encountered in petrochemical processes. Overall, their utilization helps ensure the safe and efficient operation of petrochemical facilities.

What are the properties of aluminosilicate-based refractory materials?

Aluminosilicate-based refractory materials possess several key properties. They exhibit high temperature stability, allowing them to withstand extreme heat without significant degradation. These materials also possess excellent thermal insulation properties, minimizing heat transfer and providing efficient energy conservation. Additionally, aluminosilicate refractories demonstrate good chemical resistance, making them suitable for use in corrosive environments. They have high mechanical strength and abrasion resistance, ensuring their durability and longevity. Furthermore, they exhibit low thermal expansion, reducing the risk of cracking or spalling under thermal stress. Overall, aluminosilicate-based refractory materials are versatile and reliable solutions for applications requiring resistance to high temperatures and harsh conditions.

What are the refractory raw materials used in lining calciners?

The refractory raw materials commonly used in lining calciners include magnesite, dolomite, alumina, and silica. These materials are selected for their high heat resistance and ability to withstand the harsh conditions inside the calciner, such as high temperatures and chemical reactions. The specific composition of the lining material may vary depending on the type of calciner and the process being carried out.

What are the advantages of using chrome ore in refractory applications?

There are several advantages of using chrome ore in refractory applications. Firstly, chrome ore has high thermal stability, allowing it to withstand extreme temperatures without losing its structural integrity. This makes it ideal for lining furnaces, kilns, and other high-temperature environments. Additionally, chrome ore has excellent corrosion resistance, which protects the refractory lining from chemical attack and prolongs its lifespan. Furthermore, chrome ore has good thermal conductivity, ensuring efficient heat transfer within the refractory material. Lastly, chrome ore contributes to the formation of stable refractory oxide phases, enhancing the overall performance and durability of refractory products.

Wholesale Raw Materials For Refractory from supplier in Bangladesh

Whether you are in the steel, cement, glass, or any other industry that requires refractory materials, we have the expertise to assist you. Our team of professionals is committed to delivering exceptional customer service and ensuring that you have access to the highest quality raw materials available in the market.

We offer a wide range of raw materials for refractory applications, including various types of clay, silica, alumina, and magnesia. These materials are sourced from reliable suppliers and undergo rigorous quality control procedures to ensure their suitability for your specific requirements.

In addition to providing top-quality products, we also offer comprehensive technical support services. Our team of experts can assist you in selecting the right materials for your application, provide guidance on proper installation and maintenance, and help troubleshoot any issues that may arise. We are dedicated to ensuring that you have the necessary support to optimize the performance and longevity of your refractory products.

When you choose us as your supplier of raw materials for refractory in Bangladesh, you can expect timely and reliable delivery, competitive pricing, and a commitment to your satisfaction. We are proud to be a trusted partner for numerous industries in Bangladesh, and we look forward to serving your refractory material needs. Contact us today to discuss your requirements and discover how we can add value to your projects.

We offer a wide range of raw materials for refractory applications, including various types of clay, silica, alumina, and magnesia. These materials are sourced from reliable suppliers and undergo rigorous quality control procedures to ensure their suitability for your specific requirements.

In addition to providing top-quality products, we also offer comprehensive technical support services. Our team of experts can assist you in selecting the right materials for your application, provide guidance on proper installation and maintenance, and help troubleshoot any issues that may arise. We are dedicated to ensuring that you have the necessary support to optimize the performance and longevity of your refractory products.

When you choose us as your supplier of raw materials for refractory in Bangladesh, you can expect timely and reliable delivery, competitive pricing, and a commitment to your satisfaction. We are proud to be a trusted partner for numerous industries in Bangladesh, and we look forward to serving your refractory material needs. Contact us today to discuss your requirements and discover how we can add value to your projects.

Hot Search

- Monolithic Refractories in Malawi

- Ceramic Fiber Products in Bengal

- Refractory Bricks in Ecuador

- Raw Materials For Refractory in Liechtenstein

- Refractory Bricks in Tunisia

- Refractory Bricks in Kiribati

- Monolithic Refractories in Guatemala

- Refractory Bricks in Argentina

- Raw Materials For Refractory in Libya

- Ceramic Fiber Products in Japan