All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

What are the different manufacturing methods for refractory bricks?

The different manufacturing methods for refractory bricks include dry pressing, extrusion, slip casting, and firing.

Can refractory bricks be used for carbon black reactors?

Yes, refractory bricks can be used for carbon black reactors. Refractory bricks are designed to withstand high temperatures and chemical reactions, making them suitable for use in carbon black reactors which operate at elevated temperatures and involve the production of carbon black through a complex chemical process.

How do refractory bricks contribute to the reduction of operational risks?

Refractory bricks contribute to the reduction of operational risks by providing high heat resistance and thermal insulation. They are designed to withstand extreme temperatures and protect the surrounding equipment and structures from heat damage. This reduces the risk of equipment failure, structural collapse, and fire hazards, ensuring safer and more reliable operations in industries such as metal production, glass manufacturing, and petrochemical processing.

Wholesale Refractory Bricks from supplier in Armenia

Whether you are in need of high-quality refractory bricks for industrial furnaces, kilns, or other high-temperature applications, we have the expertise and resources to meet your requirements. Our team of experienced professionals can assist you in selecting the right refractory bricks for your specific needs, taking into consideration factors such as temperature, chemical resistance, and durability.

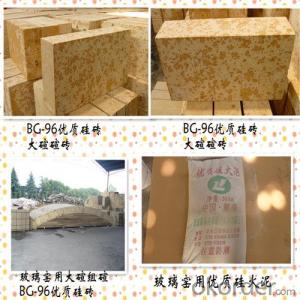

We offer a wide range of refractory bricks, including fire clay bricks, high alumina bricks, silica bricks, magnesia bricks, and insulating bricks. Each type of brick has unique properties and applications, and our experts can guide you in choosing the most suitable option for your project.

In addition to supplying refractory bricks, we also provide comprehensive sales and quotation services. Our team can assist you in understanding the pricing and availability of our products, ensuring that you receive competitive prices and timely delivery.

Furthermore, we offer technical support services to help you with any challenges or questions you may have regarding the installation and maintenance of refractory bricks. Our knowledgeable team can provide guidance on proper brick installation techniques, as well as troubleshooting advice for any issues that may arise.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and partnerships. This enables us to provide you with all-inclusive procurement solutions, ensuring that your refractory brick needs are met efficiently and effectively.

With our extensive product range, years of market development in Armenia, and commitment to customer satisfaction, we are confident in our ability to provide valuable expertise and solutions for your refractory brick projects. Contact us today to discuss your needs and let us assist you in finding the right refractory bricks for your application.

We offer a wide range of refractory bricks, including fire clay bricks, high alumina bricks, silica bricks, magnesia bricks, and insulating bricks. Each type of brick has unique properties and applications, and our experts can guide you in choosing the most suitable option for your project.

In addition to supplying refractory bricks, we also provide comprehensive sales and quotation services. Our team can assist you in understanding the pricing and availability of our products, ensuring that you receive competitive prices and timely delivery.

Furthermore, we offer technical support services to help you with any challenges or questions you may have regarding the installation and maintenance of refractory bricks. Our knowledgeable team can provide guidance on proper brick installation techniques, as well as troubleshooting advice for any issues that may arise.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and partnerships. This enables us to provide you with all-inclusive procurement solutions, ensuring that your refractory brick needs are met efficiently and effectively.

With our extensive product range, years of market development in Armenia, and commitment to customer satisfaction, we are confident in our ability to provide valuable expertise and solutions for your refractory brick projects. Contact us today to discuss your needs and let us assist you in finding the right refractory bricks for your application.

Hot Search

- Monolithic Refractories in Rwanda

- Ceramic Fiber Products in Malawi

- Refractory Bricks in Zimbabwe

- Raw Materials For Refractory in Nicaragua

- Ceramic Fiber Products in Botswana

- Refractory Bricks in Sweden

- Ceramic Fiber Products in Monaco

- Monolithic Refractories in Maldives

- Refractory Bricks in Norway

- Ceramic Fiber Products in Moldova