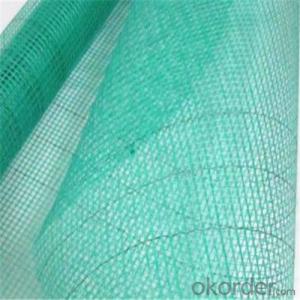

1708 Fiberglass Roll

1708 Fiberglass Roll Related Searches

Led Light Bulbs For Ceiling Fixtures Decorative Ceiling Plate For Light Fixture Ceiling Plate For Hanging Light Fiberglass Sheets For Roofing Track Lights For Kitchen Ceiling Lights For Kitchen Ceiling Lights For Fall Ceiling Spotlight For Ceiling 5 Blade Ceiling Fan With Light 12X12 Ceiling Tiles With HolesHot Searches

Fiberglass Scaffolding For Sale Plastic Roof Tiles For Sale Fiberglass Panels For Sale Fiberglass Greenhouses For Sale Cost Of Concrete Tile Roof Roof Insulation Price Artificial Slate Roof Tiles Price Ceiling Fan Lowest Price Tesla Solar Roof Inverter Types Of Flat Roof Coverings Stone Wall Tiles Cost Company Office Design Ceramic Roof Tiles Cost Metal Roof Tiles Prices Cement Roof Tile Manufacturers Clay Roof Tile Manufacturers Synthetic Roof Tiles Cost Roof Clay Tiles Prices Interlocking Roof Tiles Prices 30 Year Roof Shingles Prices1708 Fiberglass Roll Supplier & Manufacturer from China

Okorder.com is a professional 1708 Fiberglass Roll supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest 1708 Fiberglass Roll firm in China.Hot Products

FAQ

- Yes, fiberglass fabric is generally resistant to chemicals in industrial settings. Fiberglass is a synthetic material made from fine fibers of glass, which gives it excellent resistance to a wide range of chemicals, including acids, alkalis, solvents, and oils. This makes it well-suited for use in industries where there is exposure to various chemicals, such as chemical processing, petrochemical, and pharmaceutical industries. Fiberglass fabric is also known for its high temperature resistance and flame retardant properties, further enhancing its suitability for industrial settings. However, it is important to note that the specific resistance of fiberglass fabric to chemicals may vary depending on the specific type and concentration of the chemical being used, so it is always recommended to consult the manufacturer's specifications or conduct compatibility tests before using fiberglass fabric in a particular industrial application.

- Yes, fiberglass fabrics can be used for insulation purposes. Fiberglass fabrics are made from extremely fine glass fibers that are woven together to form a flexible and lightweight material. This fabric has excellent insulation properties due to its ability to trap air and prevent the transfer of heat or cold. Fiberglass fabrics are commonly used in various insulation applications, including the insulation of pipes, ducts, walls, and roofs. They are also used in the manufacturing of thermal blankets and curtains for insulation purposes. Additionally, fiberglass fabrics can be used in combination with other insulating materials to enhance their overall effectiveness. One of the key advantages of using fiberglass fabrics for insulation is their high thermal resistance. They have a low thermal conductivity, which means that they can significantly reduce heat transfer and maintain stable temperatures in the insulated areas. Fiberglass fabrics are also non-combustible and have good resistance to moisture and chemicals, making them suitable for a wide range of insulation applications. Furthermore, fiberglass fabrics are easy to handle and install. They can be easily cut and shaped to fit specific dimensions, and they can be attached to surfaces using mechanical fasteners or adhesive. This flexibility and ease of installation make fiberglass fabrics a popular choice for both residential and commercial insulation projects. In summary, fiberglass fabrics are an excellent choice for insulation purposes. Their high thermal resistance, durability, and ease of installation make them a versatile and effective solution for various insulation applications.

- Yes, fiberglass fabric can be used as insulation in pipelines. It is commonly used due to its excellent thermal and mechanical properties, including high temperature resistance, low thermal conductivity, and durability. It helps to prevent heat loss or gain, maintain consistent temperatures, and improve energy efficiency in pipeline systems.

- Is high strength fiberglass cloth the same as high silica fiberglass cloth?

- For example, high silica glass fiber cloth commonly used wellav glass. Therefore, high silica glass fiber cloth contained in the high strength glass fiber cloth, belonging to the concept of containing.

- What are the cracks between the brick wall and the beam column, the cracks between the planks and the cracks in the plasterboard?

- Cracks in masonry and beams and columns can be nailed at the junction of steel mesh or glass fiber cloth, and then plastering;

- Yes, fiberglass fabric can be used in wet or humid environments as it is resistant to moisture and does not easily degrade or warp.

- Fiberglass fabric is used in the production of insulation ropes as it provides excellent thermal insulation properties. The fabric is woven into ropes, which are then used to fill gaps and spaces in insulation systems, preventing heat transfer and maintaining energy efficiency. The fiberglass fabric's high resistance to heat, chemical corrosion, and its ability to withstand high temperatures make it a suitable material for insulation ropes in various industries.

- The process of recycling fiberglass fabric involves multiple steps and utilizes different techniques and technologies to convert used or waste fiberglass materials into new products. Typically, the recycling process consists of the following steps: 1. Waste Collection: Initially, the waste materials of fiberglass fabric are gathered. This can be accomplished through various methods, such as waste management systems, industrial recycling programs, or specialized collection centers. 2. Sorting: Once collected, the fiberglass fabrics are sorted based on their type, color, and condition. This sorting process assists in determining the suitable recycling methods and potential applications for the recycled material. 3. Shredding: Subsequently, the sorted fiberglass fabrics are shredded into smaller pieces or fibers. This fragmentation facilitates the handling and processing of the material in subsequent stages. 4. Cleaning: The shredded fiberglass undergoes a thorough cleaning process to eliminate any contaminants or impurities. Typically, this involves washing the material with water and detergents to ensure it is free from any residues. 5. Resizing: After cleaning, the fiberglass fibers may undergo a resizing process to achieve a consistent length or size. This step is crucial for ensuring uniformity in the final product. 6. Melting: The resized fiberglass fibers are then subjected to high temperatures, causing them to melt. This melting or liquefying process transforms the fibers into a molten state, making them easier to manipulate and shape. 7. Reinforcement: Once melted, the fiberglass can be used as a reinforcing material. It is commonly combined with resins like polyester or epoxy to create composite materials used in various industries, including construction, automotive, and aerospace. 8. Molding: The molten mixture of fiberglass and resin is molded into desired shapes or forms using techniques like injection molding, compression molding, or pultrusion. This enables the recycled fiberglass to be transformed into new products, such as insulation, panels, pipes, or even sporting goods. 9. Final Processing: After molding, the newly formed fiberglass products may undergo additional processes, such as curing, cooling, or surface finishing, to enhance their properties and ensure their quality. 10. Market Distribution: Finally, the recycled fiberglass products are packaged and distributed to the market, where they can be purchased and utilized by various industries and consumers. Overall, the recycling of fiberglass fabric is a complex process that aims to repurpose and transform waste materials into valuable products, reducing the environmental impact of fiberglass waste and promoting a more sustainable approach to manufacturing and consumption.