silica fiberglass cloth with vermiculite coated

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Image:

Product Description & Application:

Vermiculite coated silica Fiberglass cloth is high-temperature resistant products, made by silica glass fiber cloth coat with vermiculite.

Application:

Widely use as heat resistant and ablation-resistant material for rocket, missile and space vehicle;

High-temperature resistant, thermal insulation, refractory material;

Dust collect for high temperature gas;

Liquid filtration & Sound absorbing and thermal insulation for vehicle, motor bicycle;

The thermal insulation protective materials for molten liquid filtration.

Product Capability:

Higher temperature resistant, higher thermal insulation, low thermal conductivity;

Thermal stability and chemical stability;

Good dielectric performance;

High strength and easy to manufacture;

Nontoxic and harmless to the environment.

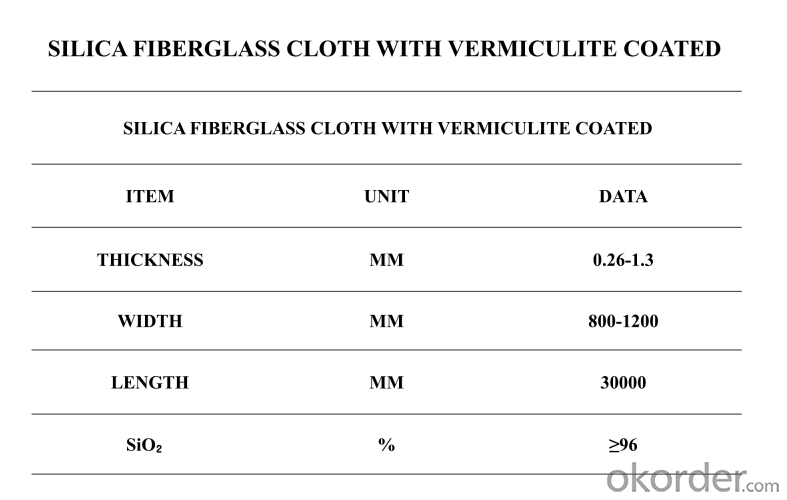

Data Sheet:

Silica fiber products: A kind of inorganic high temperature resistance fiber with the content of SiO₂ higher than 95%, its soften temperature can nearly reach to 1700℃.It can be used in high temperature environment below 900℃ for a long time.

- Q:How is fiberglass fabric repaired?

- Fiberglass fabric can be repaired by using a patching technique. The damaged area is typically cleaned and sanded, and then a suitable adhesive or epoxy resin is applied to attach a fiberglass patch onto the damaged section. The patch is then smoothed out and allowed to cure, ensuring a strong and seamless repair.

- Q:Two, fat and PVC paste resin paste into the sizing, coated on glass fiber cloth, so that after baking, how do not shrink?

- Diluent can also be added as a diluent substance is hydrocarbons, and their boiling point should be 100~200 degrees. But in any case, the boiling point of the diluent used should be lower than the dispersant. Some swelling effect of aromatics is on PVC resin, almost no Naphthalene Hydrocarbons, aliphatic hydrocarbon is not completely.

- Q:Problems in making FRP models and models

- Method of making die at the end of the lowest cost, is artificial cutting and polishing, wood or other materials can have certain hardness and easy processing stuff, but it requires a very high skill, good feel, and often do it is not precise enough, but for ship model, basically is sufficient.

- Q:How is fiberglass fabric cut and shaped?

- Fiberglass fabric is typically cut and shaped using a few different methods. One common method is to use scissors or a utility knife to cut the fabric to the desired size and shape. This method is commonly used for smaller or more intricate cuts. For larger cuts or more precise shaping, a technique called "hot knife cutting" is often employed. This involves using a heated blade or wire to cleanly cut through the fiberglass fabric. The heat helps to seal the edges of the fabric, preventing fraying and ensuring a smooth finish. Another method used for shaping fiberglass fabric is molding. In this process, the fabric is laid over a mold or form and then a resin or adhesive is applied to secure it in place. The fabric is then allowed to cure or harden, taking on the shape of the mold. This method is commonly used in the production of fiberglass products such as boat hulls or automotive parts. Overall, the cutting and shaping of fiberglass fabric requires precision and attention to detail. Whether using scissors, a hot knife, or molding techniques, it is important to ensure clean cuts and proper shaping in order to achieve the desired result.

- Q:Can fiberglass fabric be used for boat covers?

- Indeed, boat covers can utilize fiberglass fabric. Notably, fiberglass fabric is renowned for its robustness and resilience, rendering it an exceptional option for safeguarding boats against diverse weather elements. Its resistance to water, UV rays, and mildew guarantees the boat's utmost protection. Moreover, fiberglass fabric's lightweight nature and ease of handling make it exceptionally convenient for covering and uncovering boats. Furthermore, it can be effortlessly tailored to match the precise dimensions of the boat, ensuring a snug and secure fit. In summary, fiberglass fabric is a dependable and pragmatic choice for boat covers.

- Q:Can fiberglass fabrics be used for gasketing or sealing purposes?

- Yes, fiberglass fabrics can be used for gasketing or sealing purposes. They have excellent thermal and chemical resistance properties, making them suitable for applications where a high level of heat or chemical resistance is required. Additionally, fiberglass fabrics have good tensile strength and can provide a reliable and durable seal, making them an effective choice for gasketing and sealing applications.

- Q:How do fiberglass fabrics perform in terms of dimensional stability?

- Fiberglass fabrics are known for their excellent dimensional stability. They have a low coefficient of thermal expansion, meaning they do not significantly expand or contract with changes in temperature. This property ensures that fiberglass fabrics maintain their shape and size, making them highly reliable for various applications where dimensional stability is crucial.

- Q:Can fiberglass fabric be used for making aircraft parts?

- Aircraft parts can indeed be made using fiberglass fabric. Fiberglass, being a material that is both strong and lightweight with excellent mechanical properties, is well-suited for various uses in the aerospace field. Its usage in constructing aircraft parts such as fuselages, wings, fairings, and interior components is quite common. To manufacture fiberglass fabric, thin strands of glass fibers are woven together, resulting in a material that is flexible and adaptable. It possesses a high strength-to-weight ratio, resistance to corrosion, and exceptional thermal insulation properties. These particular characteristics make fiberglass fabric an excellent choice for aircraft production, as it aids in reducing the overall weight of the aircraft while maintaining structural integrity. Moreover, fiberglass fabric is easily moldable into intricate shapes, enabling the production of aerodynamically efficient aircraft components. It can also be impregnated with resins to create a composite material, which further enhances its strength and durability. However, it is crucial to note that fiberglass alone may not suffice for all aircraft parts. In certain instances, it may be used in conjunction with other materials or employed as a reinforcement layer in composite structures. The selection of materials for aircraft parts must take into account the specific requirements and regulations of the aviation industry. Nonetheless, fiberglass fabric remains a viable option for certain applications.

- Q:Is fiberglass fabric suitable for use in aerospace interiors?

- Yes, fiberglass fabric is suitable for use in aerospace interiors. Fiberglass fabric is known for its excellent strength-to-weight ratio and fire resistance, making it an ideal material for various applications in the aerospace industry. It is commonly used in the construction of aircraft interiors, including walls, ceilings, seats, and insulation. One of the primary reasons fiberglass fabric is preferred in aerospace interiors is its high strength. It offers exceptional durability and can withstand the rigorous conditions and vibrations experienced during flights. Additionally, its lightweight nature helps reduce the overall weight of the aircraft, resulting in improved fuel efficiency. Moreover, fiberglass fabric is inherently fire-resistant, which is crucial for ensuring the safety of passengers and crew members. In the event of a fire, fiberglass fabric will not ignite or contribute to the spread of flames, providing valuable time for evacuation and minimizing the risk of a catastrophic incident. Furthermore, fiberglass fabric is highly versatile and can be easily molded and shaped to fit the specific design requirements of aerospace interiors. It can be used as a structural material, providing stiffness and support, or as a decorative element, enhancing the aesthetic appeal of the cabin. In summary, fiberglass fabric offers numerous advantages that make it suitable for use in aerospace interiors. Its strength, lightweight nature, fire resistance, and versatility make it an excellent choice for ensuring the safety, durability, and functionality of aircraft cabins.

- Q:How to use silica gel cloth and glue?

- Silicone fiber cloth is divided into 2 kinds of adhesion, silica gel and fiber cloth

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

silica fiberglass cloth with vermiculite coated

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords