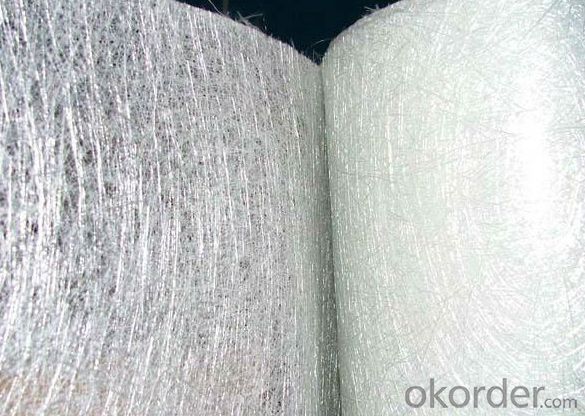

E-glass Chopped Strand Mat 2500mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 BOX kg

- Supply Capability:

- 1000MT kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Breif Introduction

Our chopped strand mat is with width 2500mm, packing in wooden box (pallet)with width 2550mm. In each 40HQ can be loaded 16-18 boxes(pallets), qualitu is around 2000kgs in each container.

2.Main Features

Our chopped strand mat factory specializes in manufacturing E-glass Chopped strand Mat (chopped strand mat manufacturer). The products range from chopped strand mat 300g/m2, chopped strand mat 450g/m2 to chopped strand mat 600g/m2 and 900g, the width from 102cm,104cm,125cm to 320cm.

Standard Specifications for Chopped strand mat

1. High quality

2. ISO9001, 2008 quality controled

3. 320cm width, 100g,300g,450gto 900g

3.Specifications

Product code | Glass type | Unite weight (g/m2) | Width(mm) | Roll weight (kg) | Moisture (%) | Binder content (%) |

100 | E Glass | 100+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4 |

150 | E Glass | 150+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4

|

200 | E Glass | 200+/-20 | 200-3200 | 30-70 | <0.2-0.3 |

3-4

|

300 | E Glass | 300+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4

|

| 450 | E Glass | 450+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4

|

600 | E Glass | 600+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4

|

900 | E Glass | 900+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4

|

Package for Big Width Mat:

1, Each roll will be wound on 4 inches paper core, strong enough for the loading and transportation;

2, Each roll of mat will be wrapped by plastic film;

3, 9 Rolls wil be packed in one wooden frame box;

4, Both side closed by polywood;

5, Steel strip is used for fasten the wooden box.

4. FAQ:

1. Why Choose us?

CNBM is a stated own company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

d, Sample stock for one year for quality tracing and record.

3. What is your MOQ?

1000kgs;

4. Can you provide sample?

Yes, we can offer free sample for you.

5. Payment terms?

Accept L/C, T/T etc.

6. Do you offer OEM service?

Yes, we can print customers’ logo on the packaging;

7. What is the Production Lead Time?

1 *40HQ each day, depend on the size of the mat.

- Q:Is fiberglass mat tissue suitable for insulation in chemical processing plants?

- Yes, fiberglass mat tissue is suitable for insulation in chemical processing plants. It is highly resistant to corrosion and chemicals, making it an ideal choice for such environments. Additionally, fiberglass mat tissue offers excellent thermal insulation properties, helping to maintain optimal temperature levels in the plant.

- Q:Can fiberglass mat tissue be used for making swimming pool shells?

- Swimming pool shells can indeed be constructed using fiberglass mat tissue. This material, widely used in the construction and manufacturing industries, possesses remarkable qualities. By combining fine glass fibers with a resin binder, it becomes a lightweight and pliable substance. The utilization of fiberglass mat tissue in swimming pool shell fabrication yields numerous advantages. Primarily, its exceptional resistance to water enables it to excel in pool applications. It also withstands the effects of common pool chemicals like chlorine, ensuring the longevity of the shell. In addition, fiberglass mat tissue is highly adaptable and can be molded into various shapes and sizes. This permits the creation of bespoke swimming pool shells that cater to specific requirements and preferences. Its flexibility also enables it to endure ground movement and temperature changes, thereby guaranteeing the pool shell's structural integrity. Moreover, fiberglass mat tissue boasts a smooth surface finish, providing both visual and tactile appeal. It can be easily painted or coated with gel coats to enhance its appearance and safeguard it from harmful UV rays, preventing discoloration and deterioration over time. In conclusion, fiberglass mat tissue emerges as an exceptional option for constructing swimming pool shells due to its water and chemical resistance, flexibility, durability, and aesthetic appeal.

- Q:What are the different types of fiberglass mat tissue available in the market?

- There are several types of fiberglass mat tissue available in the market, including chopped strand mat (CSM), continuous filament mat (CFM), and surfacing mat. Chopped strand mat is made up of randomly oriented short glass fibers held together with a binder, providing good strength and conformability. Continuous filament mat consists of long continuous glass fibers, providing higher strength and stiffness. Surfacing mat, on the other hand, is a thin layer of fiberglass mat used to improve the surface finish and appearance of the final product.

- Q:Can fiberglass mat tissue be used for insulation in chemical storage tanks?

- Yes, fiberglass mat tissue can be used for insulation in chemical storage tanks. Fiberglass is known for its excellent insulation properties, making it a suitable material for insulating tanks that store chemicals. The fiberglass mat tissue is typically made from fine glass fibers that are woven together to create a strong and durable material. This mat tissue can be applied to the inner walls of the tank to provide insulation and prevent heat transfer. Additionally, fiberglass is corrosion-resistant and can withstand the harsh chemicals often stored in these tanks, making it an ideal choice for insulation in chemical storage tanks.

- Q:Does fiberglass mat tissue require any special tools for installation?

- Yes, fiberglass mat tissue may require some special tools for installation. These tools can include a utility knife or scissors for cutting the mat to the desired size, a roller or brush for applying adhesive or resin to secure the mat to the desired surface, and safety equipment such as gloves and goggles to protect the installer from potential hazards. Additionally, some installations may require the use of a heat gun or torch to activate or cure the resin. It is important to read and follow the manufacturer's instructions and recommendations for the specific fiberglass mat tissue being used to ensure proper installation and to determine if any special tools are required.

- Q:How does the thickness of fiberglass mat tissue affect its performance?

- The thickness of fiberglass mat tissue plays a crucial role in determining its performance. Thicker fiberglass mat tissues generally provide better strength and durability compared to thinner ones. A thicker mat tissue allows for a higher resin-to-glass ratio, resulting in improved stiffness and toughness. This increased resin content enhances the overall structural integrity and mechanical properties of the fiberglass mat tissue. It also helps to minimize the risk of delamination and improves resistance to impact and fatigue. Moreover, thicker fiberglass mat tissues are more effective in providing thermal and acoustic insulation. The increased thickness allows for a higher density of fibers, which enhances the material's ability to trap air and reduce heat transfer or sound transmission. However, it is important to note that the specific application and requirements should be considered when determining the appropriate thickness of fiberglass mat tissue. While thicker tissues generally offer better performance, they may also be heavier and more expensive. Therefore, a balance must be struck between the desired performance characteristics and the practical considerations of weight, cost, and ease of installation.

- Q:Can fiberglass mat tissue be used for corrosion-resistant applications?

- Yes, fiberglass mat tissue can be used for corrosion-resistant applications. Fiberglass mat tissue is made from fine glass fibers bonded with a resinous binder, which provides excellent corrosion resistance properties. The tissue is designed to be used as a barrier layer in various corrosion-resistant applications such as in the construction of tanks, pipes, and vessels that are exposed to corrosive environments. The fiberglass mat tissue acts as a protective barrier, preventing the penetration of corrosive elements and enhancing the durability and longevity of the structure. Additionally, the tissue is lightweight, easy to handle, and can be easily molded into complex shapes, making it an ideal choice for corrosion-resistant applications.

- Q:Does fiberglass mat tissue provide any sound insulation?

- Indeed, sound insulation is indeed provided by fiberglass mat tissue. This widely-used material finds application in diverse industries such as construction and automotive, where its purpose is to absorb and diminish sound transmission. By means of its fibrous composition, this material efficiently seizes and absorbs sound waves, effectively preventing their penetration through walls or other surfaces. Frequently employed as acoustic insulation, fiberglass mat tissue contributes to the creation of a pleasant and serene atmosphere in walls, floors, and ceilings.

- Q:What is the impact resistance of fiberglass mat tissue?

- The impact resistance of fiberglass mat tissue is generally high due to the reinforcing properties of the fiberglass strands, which help to absorb and distribute impact forces.

- Q:Can fiberglass mat tissue be used for repairing fiberglass fenders?

- Yes, fiberglass mat tissue can be used for repairing fiberglass fenders. It is commonly used in fiberglass repair work to reinforce and strengthen damaged areas.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

E-glass Chopped Strand Mat 2500mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 BOX kg

- Supply Capability:

- 1000MT kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords