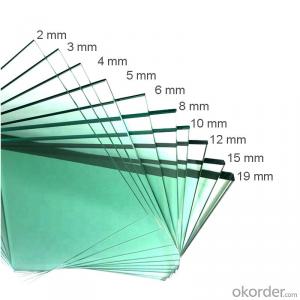

Fire Proof Clear Borosilicate Float Glass 4.0 with thickness 2mm-19mm

- Loading Port:

- QINGDAO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 100 m.t./month

- Option:

- 4.0

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Description:

Borosilicate glass, also known as high borosilicate glass, is known as the "King of Glass". Its main component is about 80% silicon oxide and about 10% boron oxide. At this time, both silicon oxide and boron oxide can basically form microtetrahedrons. Framework (the more the micro tetrahedral framework in the glass is, the greater the ionic bond force will become, contributing to a more stable performance), the other is about 5% of stable oxide and about 5% of flux.

Name | tempered glass |

shape | can make as customer’s request |

Glass Type | Tempered Glass |

place of origin | China |

Structure | solid |

Packing | Meet customer's personal requirement |

Color | clear blue green bronze grey pink |

Size | 600*800 2200*1650 2440*1830 3300*2140 3660*2140 3660*2440 |

Packing | Wooden box |

Function | Acid Etched Glass, Bulletproof Glass, Decorative Glass, Insul |

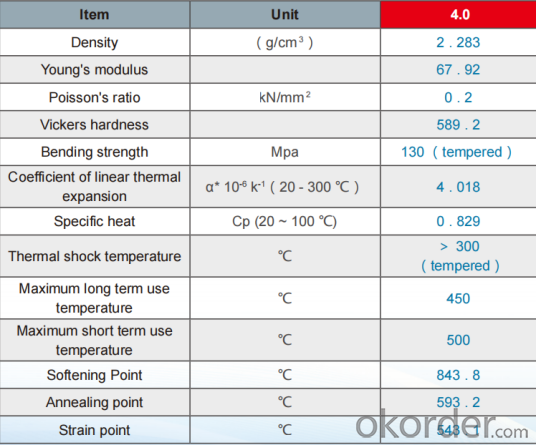

2. Actual measured parameters of Borosilicate Glass:

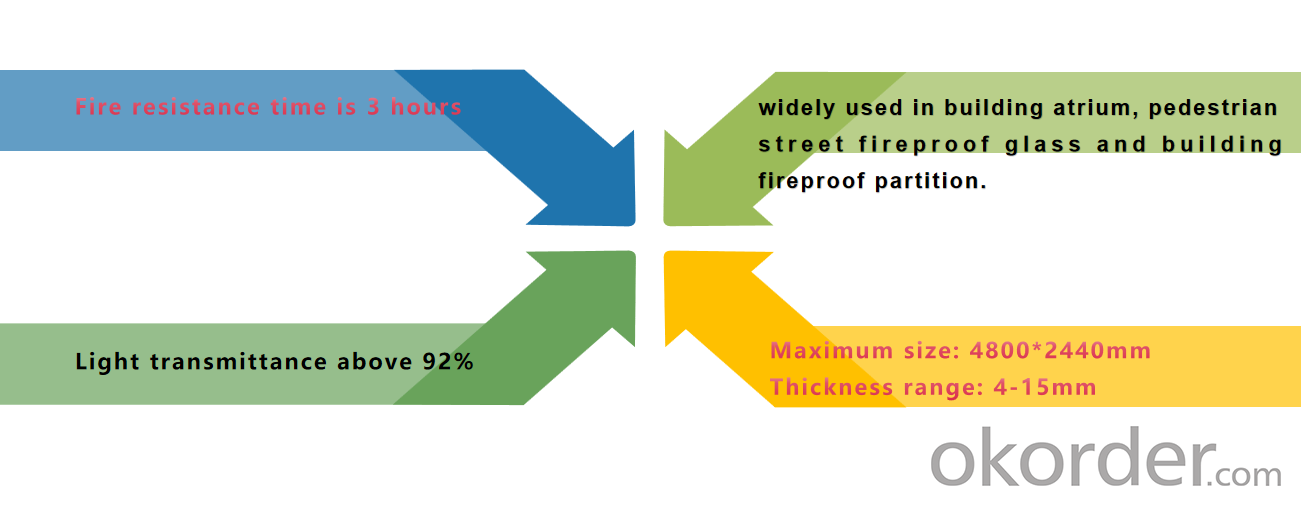

3. Main features:

4. Advantage:

Float Glass is superior in quality when compared to other flat glass and has the unique characteristics of excellent surface finishing, flatness, uniform thickness, high optical quality and bright appearance. The float process was invented in 1952.

Float technology has rapidly replaced plate and sheet facilities worldwide in recent decades. Float glass derives its name from the float process used where the molten glass floats on the top of molten tin.

5. Application Area: Can be used in fireproof curtain walls, partition walls, platforms, day lighting roofs, smoke-proof vertical walls, railings, doors and windows, elevator shafts, rail transit platform screen doors, rail locomotive doors and windows and other fields. Equipped with water spray, it can be used to replace Class A insulation type fireproof glass system, which can be widely used in building atrium, pedestrian street fireproof glass and building fireproof partition.

6. Engineering Case

|

1. Name: Xiongan train station 2. Max.size: 4000*2200mm 3. Glass structure: laminated, hollow |

|  Borosilicate 4.0 fire-resistant glass Borosilicate 4.0 fire-resistant glass1. Name: Shenzhen airport 2. Max.size: 3585*1915mm 3. Glass structure: laminated |

|

1. Name: Shanghai Center Building 2. Max.size: 2694*1215mm 3. Glass structure: monolithic |

More Applications:

7. Process:

8. Packing and Shipping:

All the glass will pack in strong export plywood crates, and load in container strong firmly, to make sure safety delivery.

9. Test Report:

10. Company Brief:

11. FAQ:

Q1:What’s your MOQ?

A: Generally, there is 2 tons for MOQ , CNBM will give you more discount if quantity more.

Q2:Can you send me some samples to check your quality?

A:Sure, CNBM Glass could send the free samples (except special deep processing glass) for you any time. we will refund the courier charge for you once we start business.

Q3:What's the fast production time you can do?

A: It depends on the quantity of building glass you need. Normally it takes 15-45 days after drawing confirmed.

Q4:How can you make sure the glass won't broken during transportation?

A: For all the glass from our factory,we will pack them into strong export plywood crates and load the crates into container with metal belt as stable as possible. If unfortunately by accident, the glass broken, we will have insurance to cover the risk, because for all the glass from our company, we will purchase the insurance to cover all the risk for customers freely.

Q5:How can i get the best price?

In order to offer our best price for you, please send all the details as below for us:

a. what size and thickness of clear float glass/tempered glass/laminated glass are you looking for?

b. How about the approximate quantity?

c. Do you have any special requirement like drill holes, cut notches,cutouts, acid etched, silkscreen?

d. When do you need those glass?

- Q:How can the invisible gauze of screen window increase its pressure resistance (glass fiber material)?

- To have good quality, if the quality of other yarn nets, there may be broken.

- Q:What does GF30 represent in plastic PP GF30?

- Polypropylene reinforced by glass fiber, mechanical properties, creep resistance and dimensional stability can be improved,.PP-GF30T has a good low-temperature resistance and high impact strength, PP-GF30 heat resistance

- Q:A fireproof material is? Except glass wool, rock wool? Please tell me what is the raw material of these materials is?

- The performance of phenolic insulation board: 1, excellent fireproof performance: polyurethane and polystyrene and other organic materials, after combustion, will produce smoke and poisonous, easy to cause the deaths, but also increase the difficulty of fire suppression. The phenolic insulation board fire burning, combustion performance up to grade A, the high temperature of 180 DEG C (instantaneous 250 C), 100 mm thick phenolic foam flame resistant capacity of up to 1 hours without penetration. With carbon, no dripping, no curling, no melting phenomenon in the direct effect of flame, the flame surface to form a layer of graphite foam layer, the foam structure effective protection layer in 2, the excellent; insulation properties: low thermal conductivity (

- Q:Will toughened glass break naturally?

- A ton of glass raw materials, at least 3-4 of nickel sulfide crystals, the number of tons of glass made of pieces of a square size glass, which will have 3-4 to explode, which is self depicting the image of.

- Q:Tempered glass and ordinary glass raw materials the same, but the manufacturing method is different, why first heating in rapid cooling, the difference is so great?

- Ordinary glass float line cooling is a long process, the glass also has compressive stress, but the compressive stress is small, uneven distribution

- Q:Not man-made destruction, why toughened glass suddenly broken?

- This is because of containing nickel sulfide crystal glass raw material, manufacturing technology in the world is any existing can not be completely avoided, only reduce the exploding probability through control of the purity of raw materials and processing technology to a.It blew the concept of rate, the national standard of our country only glass project on the wall, I do not know whether the other foreign industry to use the toughened glass also has detailed provisions.

- Q:What materials are needed for the production of glass bottles and what are their proportions?

- The glass is the main component in the manufacturing process of quartz sand, quartz sand is combined with other chemical materials at high temperature (1300 degrees Celsius) crystallized after firing the cooling of the body, with a hard, abrasion resistance, corrosion resistance and high transmittance characteristics, its wide application has a long history.

- Q:Use of glass flake cement

- Due to the relative stretching coefficient of the steel, cement and other material and substrate, so in the case of heat shock resin layer easily cracking and shedding, and glass flake could commission a heat stable layer, which can prevent the substrate cracking and spalling.

- Q:Samsung LCD panel information

- This screen is indeed the original Samsung screen, Samsung Electronics, Tianjin Corporation assembly production.TSEC is the sign of Tianjin's samsung. So he wrote the MADE IN CHINA (TSEC) behind him

- Q:How do you make the glass, please? What is the raw material?

- If there is, use calcium carbonate, silica, and sodium carbonate in a platinum crucible or clay crucible or corundum (alumina) crucible and melt to obtain glass.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fire Proof Clear Borosilicate Float Glass 4.0 with thickness 2mm-19mm

- Loading Port:

- QINGDAO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 100 m.t./month

- Option:

- 4.0

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products