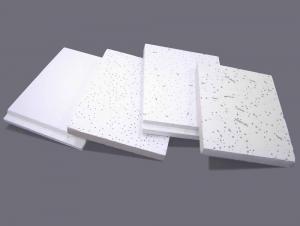

Glass Fiber Mat

Glass Fiber Mat Related Searches

Fiber Sheet For Roof Decorative Lights For Ceiling Wall Panels For Basement Marketplace For Construction Materials Retaining Wall With Geogrid Galvanized Steel Wall Panels Stainless Steel Peg Board Stainless Steel Wall Art Stainless Steel Wall Shelves Stainless Steel WallHot Searches

Used Foam Board Insulation For Sale Used Sandwich Panel For Sale Bags Of Cement For Sale Tilt Panel Props For Sale Types Of Temporary Side Panels For Cement Deck Magnesium Oxide Board For Sale Hdf Board For Sale sintra board for sale Fiber Sheet Price In India Gypsum Board Price Per Sheet In India Fiber Roofing Sheets Price In Pakistan Plastic Fiber Sheet Price Solar Inverter Panel Price Sandwich Panel Manufacturers In Bangladesh 5 8 Type X Gypsum Board Price Twin Wall Polycarbonate Sheet Price Hardiflex Fiber Cement Board Price Gypsum Board Partition Wall Price India Extruded Polystyrene Insulation Board Price Polyurethane Insulation Board PriceGlass Fiber Mat Supplier & Manufacturer from China

Okorder.com is a professional Glass Fiber Mat supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Glass Fiber Mat firm in China.Hot Products

FAQ

- Yes, fiberglass fabric can be used for making sports equipment. It is a lightweight, durable, and flexible material that is commonly used in the production of various sports equipment such as kayaks, surfboards, hockey sticks, and bicycle frames.

- Yes, fiberglass fabric can be used for indoor applications. Fiberglass fabric is a versatile material that is commonly used for various purposes including insulation, reinforcement, and structural support. It is resistant to heat, fire, chemicals, and moisture, making it suitable for indoor applications where these properties are required. Fiberglass fabric can be used in the manufacturing of products such as wall coverings, upholstery, curtains, and acoustic panels. It is also commonly used in industries such as aerospace, automotive, and construction for indoor applications. Overall, fiberglass fabric provides a durable and reliable solution for indoor applications.

- Yes, fiberglass fabric is resistant to UV discoloration. Fiberglass is known for its excellent UV resistance, making it a suitable choice for applications that are exposed to the sun for prolonged periods. The fabric is specifically designed to withstand the damaging effects of ultraviolet radiation, which can cause discoloration and degradation over time. By using fiberglass fabric, you can ensure that your materials will maintain their original color and appearance even when exposed to sunlight for extended periods.

- Yes, fiberglass fabric can be used for insulation in cryogenic applications. Fiberglass has excellent thermal insulation properties and can effectively prevent heat transfer, making it suitable for cryogenic environments where extremely low temperatures are involved. Additionally, fiberglass is resistant to moisture and chemicals, which further enhances its suitability for cryogenic insulation.

- Fiberglass fabrics have several environmental considerations to take into account. Firstly, the production process involves extracting raw materials like silica sand and limestone, which can harm the environment through habitat destruction and landscape alteration. Additionally, manufacturing fiberglass fabrics requires significant energy consumption, leading to greenhouse gas emissions and climate change. Moreover, the use of fiberglass fabrics often involves toxic chemicals like resins and adhesives, which pose risks to human health and the environment. These chemicals can potentially seep into soil and water sources, endangering ecosystems and biodiversity. Furthermore, fiberglass fabrics are not biodegradable and can persist in the environment for a long time. If not properly managed at the end of their life cycle, they can contribute to waste accumulation in landfills or incineration, both of which have negative environmental impacts. Nevertheless, it is worth noting that fiberglass fabrics have some positive environmental aspects. They are highly durable and have a long lifespan, reducing the need for frequent replacements and conserving resources. Additionally, fiberglass fabrics can save energy when used in insulation and construction materials, leading to decreased energy consumption and greenhouse gas emissions in the long term. In conclusion, while there are environmental considerations associated with fiberglass fabrics, their impact can be minimized through sustainable production practices, appropriate waste management, and the exploration of alternative, more eco-friendly materials.

- Yes, fiberglass fabrics can be used for protection against electromagnetic interference (EMI). Fiberglass has excellent electrical insulation properties and is commonly used as a shielding material in various applications. It has a high dielectric strength, low electrical conductivity, and can effectively attenuate electromagnetic waves. When used as a fabric, it can be used to create EMI shielding curtains, blankets, or covers to protect sensitive electronics and equipment from external electromagnetic radiation. The woven structure of fiberglass fabrics provides a robust and durable shielding solution while allowing for flexibility and ease of use. Additionally, fiberglass fabrics can also provide thermal insulation and fire resistance properties, making them suitable for a wide range of applications requiring EMI protection.

- Fiberglass fabric has high moisture resistance due to its inherent non-absorbent nature and the hydrophobic properties of the fiberglass material.

- Fiberglass fabric plays a crucial role in the production of insulation jackets. It is widely used as an outer layer material due to its exceptional thermal resistance, durability, and fire-retardant properties. Insulation jackets are designed to provide thermal insulation and protect various industrial equipment, pipelines, and machinery from extreme temperatures, moisture, and other environmental factors. When manufacturing insulation jackets, fiberglass fabric is typically employed as the outermost layer. This fabric is made from fine strands of glass that are woven together to form a strong and flexible textile. The structure of fiberglass fabric allows it to trap air between the fibers, creating a layer of insulation that helps to regulate temperature and prevent heat loss or gain. The fiberglass fabric used in insulation jackets is usually coated with a protective layer, such as silicone or acrylic, to enhance its resistance to chemicals, abrasion, and weathering. This coating also improves the fabric's ability to repel moisture, preventing condensation and potential damage to the insulation material. Insulation jackets made with fiberglass fabric offer several advantages. Firstly, fiberglass fabric is highly resistant to high temperatures, making it suitable for applications where insulation is required in hot environments. It can withstand temperatures ranging from -200°C to 540°C (-328°F to 1004°F), ensuring long-lasting protection for the equipment it covers. Secondly, fiberglass fabric is lightweight and flexible, allowing for easy installation and removal of the insulation jackets. Its flexibility enables it to conform to the shape of the equipment, ensuring a snug fit and optimal insulation performance. Furthermore, fiberglass fabric is known for its excellent fire resistance properties. It is inherently non-combustible and does not contribute to the spread of flames, making it a safe material to use in industrial settings. In summary, fiberglass fabric is a vital component in the production of insulation jackets. Its thermal resistance, durability, fire-retardant properties, and ability to repel moisture make it an ideal material for protecting industrial equipment from extreme temperatures and environmental factors.