Carbon Fiber Weaving Fabrics

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000KG kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product description

Among the existing structural materials, carbon fiber reinforced epoxy resin composites have the highest specific strength and modulus. In the areas of strict requirements on density, stiffness, weight, fatigue characteristics, high temperature and high chemical stability, CFRP have an outstanding advantage.

Main Features:

● Light weight

● Products high strength, high modulus

● Superior acid corrosion resistance

Product Specifications:

Density:100-400g/m2.

Item:1k,2k,3k,6k,12k.

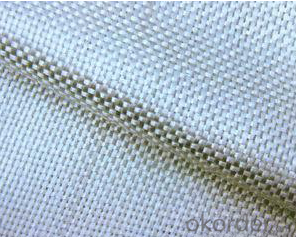

Weave:Plain,Twill,Satin,Multiaxial,UD

Packaging:

Each roll is wound onto a paper tube which has an inside diameter of 76mm and the mat roll has a diameter of 225mm. The roll is wrapped up with plastic film,and then packed in a cardboard box or wrapped up with kraft paper. The rolls can be horizontally placed. For transportation, the rolls can be loaded into a cantainer directly or on pallets.

Storage:

Unless otherwise specified, It should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

- Q:Can fiberglass fabric be used for reinforcement in automotive body panels?

- Absolutely! Automotive body panels can definitely benefit from the reinforcement provided by fiberglass fabric. This material is renowned for its exceptional strength, durability, and lightweight nature, making it the perfect choice for reinforcing body panels in cars. When combined with resins or other composite materials, fiberglass fabric offers the essential strength and rigidity required to withstand the demands of everyday use and ensure the safety of the vehicle's occupants. Moreover, the versatility of fiberglass fabric enables it to be molded into intricate shapes, granting greater flexibility in the construction of automotive body panels.

- Q:How does fiberglass fabric perform in creep resistance?

- Fiberglass fabric generally exhibits good creep resistance properties. Creep refers to the tendency of a material to deform slowly under a constant load or stress over time. Fiberglass fabric, due to its inherent structural composition and unique manufacturing process, possesses a high resistance to creep deformation. The use of glass fibers in the fabric provides excellent strength and stiffness, allowing it to withstand significant loads without experiencing permanent deformation. The fibers are tightly bound together in a matrix, typically made of epoxy or polyester resin, which further enhances the fabric's creep resistance. Moreover, the manufacturing process of fiberglass fabric involves a controlled heating and cooling cycle, known as curing, which effectively eliminates any residual stresses within the material. This eliminates the occurrence of creep caused by these internal stresses. Additionally, the epoxy or polyester resin matrix in fiberglass fabric acts as a protective layer, shielding the glass fibers from external environmental factors that may contribute to creep, such as moisture absorption or chemical degradation. Overall, fiberglass fabric is known for its excellent creep resistance, making it a suitable choice for applications that require structural stability and long-term performance under constant loads or stresses.

- Q:What is the heat resistance of fiberglass fabric?

- The heat resistance of fiberglass fabric is quite high, as it can withstand temperatures up to 1,000 degrees Fahrenheit (537 degrees Celsius) without significant damage or degradation.

- Q:What are the different weaving patterns available for fiberglass fabric?

- Fiberglass fabric comes in various weaving patterns, each with its distinct qualities and uses. The plain weave is the most fundamental and widely employed pattern. It involves a simple interlacing of warp and weft yarns, resulting in a balanced and uniform fabric structure. This type of fiberglass fabric offers good strength, dimensional stability, and versatility for different applications. Twill weave, on the other hand, creates a diagonal pattern on the fabric surface. By passing the weft yarn over multiple warp yarns before going under, this weaving technique enhances the fabric's drapability, flexibility, and ability to conform to complex shapes. Twill weave fiberglass fabric is commonly chosen for applications that require both durability and flexibility, such as in the aerospace and automotive industries. Satin weave is characterized by long floats, where the weft yarn passes over multiple warp yarns before going under. This creates a smooth and glossy surface with reduced crimp and higher yarn density. Satin weave fiberglass fabric is known for its excellent drapeability, high strength-to-weight ratio, and is often used in industries that demand a high-quality surface finish, such as marine and sporting goods. Leno weave is a unique pattern where the warp yarns are twisted together, resulting in an open and flexible structure. This weaving pattern enhances the fabric's breathability and allows for better resin impregnation during composite fabrication. Leno weave fiberglass fabric finds utility in filtration, reinforcement in composites, and as a base fabric for laminates. Finally, jacquard weave is a complex pattern achieved by controlling each warp yarn individually. This weaving technique allows for intricate designs, patterns, and textures to be woven into the fabric. Although less common in fiberglass fabric, jacquard weave can be used to create custom designs or specific functional features in specialized applications. In conclusion, the choice of weaving pattern for fiberglass fabric depends on the desired properties, performance requirements, and intended applications. Each pattern brings unique characteristics and advantages, providing numerous possibilities for utilizing fiberglass fabric across various industries.

- Q:What are the different fiberglass fabric finishes for oil resistance?

- There are various fiberglass fabric finishes available for oil resistance, including but not limited to silicone rubber coating, neoprene coating, and fluorocarbon coating.

- Q:Can fiberglass fabric be used for making air ducts?

- Yes, fiberglass fabric can be used for making air ducts. It is a lightweight, durable, and fire-resistant material that is commonly used in HVAC systems for its excellent insulation properties.

- Q:Can fiberglass fabric be used for making tents?

- Tents can indeed be made using fiberglass fabric. When it comes to constructing tents, fiberglass fabric is a favored option due to its remarkable durability, strength, and resistance to damage. Despite its lightweight nature, it offers exceptional protection against various elements, including wind, rain, and harmful UV rays. Moreover, the fiberglass fabric is fire-resistant and can retain its structural integrity even in extreme temperatures. Furthermore, it is user-friendly and can be effortlessly sewn or welded together to form tent panels. Considering all these exceptional qualities, fiberglass fabric proves to be a trustworthy material for crafting top-notch, enduring tents.

- Q:How do fiberglass fabrics perform in terms of moisture wicking?

- Fiberglass fabrics lack the typical ability to wick away moisture. Unlike fabrics made from natural fibers like cotton or wool, fiberglass fabrics do not possess inherent moisture-wicking capabilities. This is mainly because fiberglass is non-absorbent, making it difficult for moisture to be absorbed and carried away from the skin. However, it is worth noting that fiberglass fabrics can still be utilized in certain applications where moisture management is not the main concern. Fiberglass is commonly chosen for its exceptional mechanical properties, including high strength, durability, and resistance to heat, chemicals, and fire. Therefore, in industries such as automotive, aerospace, and construction, fiberglass fabrics are selected based on these advantageous characteristics rather than their ability to wick away moisture. In situations where moisture management is vital, other fabric options that possess moisture-wicking capabilities are generally preferred. Fabrics like polyester, nylon, or blends with natural fibers like cotton or bamboo are known for their ability to absorb moisture and transport it away from the body, ensuring the wearer stays dry and comfortable. To conclude, although fiberglass fabrics may not provide significant moisture-wicking properties, they are still widely used in various industries due to their numerous other advantageous characteristics.

- Q:What are the advantages of using fiberglass fabrics?

- There are several advantages of using fiberglass fabrics. Firstly, fiberglass fabrics are highly durable and have a long lifespan, making them a cost-effective choice for various applications. Secondly, they possess excellent strength-to-weight ratio, providing high strength and stiffness while remaining lightweight. Additionally, fiberglass fabrics are resistant to corrosion, chemicals, and fire, making them suitable for use in harsh environments. Lastly, they have good insulation properties, making them ideal for thermal and electrical applications.

- Q:Can fiberglass fabric be used for making stage backdrops?

- Yes, fiberglass fabric can be used for making stage backdrops. It is a versatile material that offers durability, strength, and resistance to fire, making it suitable for theatrical productions. Additionally, fiberglass fabric can be easily manipulated, allowing for various creative designs and effects on stage.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Carbon Fiber Weaving Fabrics

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000KG kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords