FRP Pultrusion Roof Tile Sheets or Panels

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500M2 m²

- Supply Capability:

- 900M2/Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

FRP Pultrusion Roof Tile Sheets or Panels

Description

In general, our company specializes in FRP grating, FRP decking, FRP platform and other products of FRP. We have a varity of FRP products sold over the country because we have our own teams of design, manufacturing and sales with hundreds of staffs.

At the same time, we are devoted to creating a production and marketing for FRP products, which has certain influence in China by proceeding with professional teams, rigorous quality management system and advanced production facility.

Today, we’re planning to win more market shares in the world and let more customers know us.

Photos

Product Traits

1. Corrosion resistance no rust, no maintenance, long service life.

2. Lightweight, high strength pultrusion process molding FRP profiles have high glass fiber content (60%). In this situation, the density of glass fiber reinforced plastic is only about a quarter of the steel.

3. The intensity and stiffness is quite prominent,.

4. Anti-fatigue high anti- fatigue strength, allowing repeated bending without permanent deformation.

5. Anti-aging select highquality FRP pultrusion profiles, the service life of the product can be more than 20 years.

6. Anti-UV agent are added into all pultrusion FRP profiles get the best anti-uv effect.

Product Advantage

Coated with prevent aging layer

Excellent insulating performance

Easy to maintain.

High strength.

Long service life.

Easy to install.

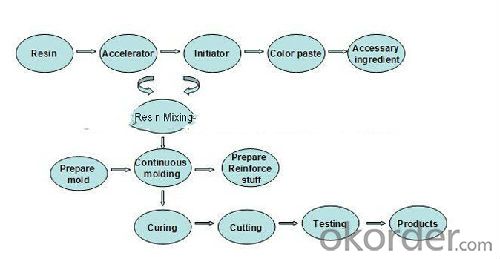

Production Process

Specification

Mechanical properties: high rigidity lighting panels

Plate matches: match with general prepainted galvanized sheet, galvanized steel

Resin composites: Improved anti-aging SMR198 resin

Fiber reinforcement: E-glass fiber untwisted without glue

Surface treatment: affixing MELINEX301 film

Stiffener line: surface with longitudinal uniform distribution of anti-LAC gluten

Glass fiber: not less than 28%

Unit Weight: 1800g / ㎡, 2400g / ㎡, 3050g / ㎡

Nominal thickness: 1.2 mm, 1.5mm, 2.0mm (tolerance ≤ 10%)

Temperature limits: -60 ℃ ~ +130 ℃

Transmittance (1.5mm): 72% ± 2% (fog white, sky blue, water green), 52% ± 2% (white porcelain)

UV-rate: 99%

Tensile strength: 90Mpa

Flexural strength: 160 Mpa

Elongation: 1.9%

Pap hardness: ≥ 50

Thermal expansion coefficient: 1.5 ~ 3.2 * 10-5 / K

Thermal conductivity: K = 0.23W / m * K

Guarantee: 15 years

NOTE: In special cases, the surface film varieties vary according to needs, such as Melinex389, PT055 and so on

FAQ

1.Which country do you mainly export to?

A: Our products are very popular in Mid East, India, South East Asia, Latin America, Africa.

2.Q: What’s the advantage of you compared with other suppliers experienced in foreign trade?

A: We have been specialized in FRP products for over decades years and approved by many domestic companies. Except for our quality and price, we’re also able to give you the best service.

3.Q:Can you provide some samples?

A: Yes, of course. We will send you samples for your confirmation before you place firm orders.

- Q:Can fiberglass fabric be used for making electronic devices?

- Fiberglass fabric is capable of being utilized in the production of electronic devices. Its remarkable thermal and electrical insulation properties have rendered it a widely employed material within the electronics industry. It is frequently employed as a substrate for printed circuit boards (PCBs) and serves as an insulating layer for various electronic components. The fabric's strength and dimensional stability make it ideal for constructing robust PCBs that are capable of enduring the heat generated by electronic components. Furthermore, fiberglass fabric is also suitable for the production of flexible PCBs, which are commonly found in wearable devices and other portable electronics. All in all, fiberglass fabric is an adaptable material that finds extensive use in the manufacture of electronic devices.

- Q:What is the weight of fiberglass fabric?

- The weight of fiberglass fabric can vary depending on the specific type and thickness of the fabric. Generally, fiberglass fabric is measured in ounces per square yard (oz/yd2) or grams per square meter (g/m2). Common weights for fiberglass fabric range from 0.5 oz/yd2 (17 g/m2) to 3.0 oz/yd2 (102 g/m2) or more. Lightweight fiberglass fabrics are often used for applications such as reinforcing and laminating, while heavier fabrics are commonly used for structural reinforcement or insulation purposes.

- Q:How is fiberglass fabric used in the production of boat hulls?

- Fiberglass fabric is extensively used in the production of boat hulls due to its exceptional strength, durability, and lightweight nature. It is a versatile material that is made by weaving together fine strands of glass into a fabric. This fabric is then impregnated with a resin, typically a polyester or epoxy resin, to create a solid and rigid composite structure. In boat hull production, fiberglass fabric is used as a reinforcement material. It is commonly applied in several layers, known as laminate, to form a strong and rigid hull. The fabric is first laid down on a mold or a frame in the desired shape of the boat. The resin is then applied over the fabric, saturating it completely and bonding the layers together. Once the resin cures and hardens, the fiberglass fabric becomes an integral part of the boat hull. It provides structural integrity, making the hull resistant to impacts, flexing, and water damage. The strength of the fiberglass fabric ensures that the hull can withstand the stresses and forces encountered during boating, such as waves, wind, and collisions. Moreover, fiberglass fabric offers excellent resistance to corrosion, rot, and degradation from exposure to water, making it an ideal choice for boat hulls. It is also relatively easy to shape and mold, allowing boat manufacturers to create hulls of various designs and sizes. Furthermore, fiberglass fabric can be easily repaired if damaged. If the hull suffers any cracks or punctures, it can be fixed by simply applying a new layer of fiberglass fabric and resin over the damaged area. This repair process ensures that the boat remains structurally sound and watertight. In summary, fiberglass fabric plays a crucial role in the production of boat hulls by providing strength, durability, and resistance to water damage. Its versatility and ability to be easily repaired make it a preferred choice for boat manufacturers worldwide.

- Q:How does fiberglass fabric perform in flexural strength?

- The excellent flexural strength properties of fiberglass fabric are well-known. This term refers to a material's ability to withstand bending or flexing without breaking or deforming. Fiberglass fabric, created by weaving fine glass fibers together, demonstrates high flexural strength due to the inherent properties of glass. The glass fibers offer exceptional rigidity and resistance to bending forces, resulting in a highly durable fabric that can endure significant flexing loads. The structure of fiberglass fabric allows for the even distribution of applied loads across its surface. This minimizes stress concentration points and prevents localized failure, enabling the material to maintain its shape and integrity even when subjected to substantial bending or flexing conditions. Furthermore, the manufacturing process of fiberglass fabric allows for tailoring the orientation and arrangement of the glass fibers, thus enhancing its flexural strength. By strategically aligning the fibers, the fabric can exhibit even greater resistance to bending forces in specific directions. Additionally, fiberglass fabric is often combined with resins or coatings to create composite materials, further enhancing its flexural strength. The resin matrix serves as a binder, offering additional support and stability to the glass fibers and improving the overall performance of the fabric. Overall, fiberglass fabric is highly regarded for its outstanding flexural strength, making it the preferred choice for applications that demand high durability and resistance to bending or flexing forces.

- Q:Is fiberglass fabric suitable for use in electrical insulation tapes?

- Yes, fiberglass fabric is suitable for use in electrical insulation tapes. Fiberglass has excellent electrical insulation properties and can withstand high temperatures, making it ideal for use in applications where electrical insulation is required. It is resistant to heat, chemicals, and moisture, which ensures long-lasting protection for electrical components. Additionally, fiberglass fabric is flexible and easy to handle, allowing for easy application on various surfaces. Overall, fiberglass fabric is a reliable and effective material for electrical insulation tapes.

- Q:How does fiberglass fabric perform in terms of fire resistance?

- The fire resistance properties of fiberglass fabric are well-known. It possesses a high melting point and does not easily ignite due to its composition of woven glass fibers. When exposed to flames, it does not burn or release harmful gases, making it suitable for applications where fire safety is of utmost importance. Furthermore, fiberglass fabric has the ability to self-extinguish, meaning that it stops burning once the heat source is removed. This characteristic aids in preventing the spread of fire and contributes to overall safety. In addition, fiberglass fabric has low thermal conductivity, meaning it does not conduct heat effectively. This property helps contain the fire and reduces the risk of its spreading. The fabric also acts as a barrier between the heat source and the surrounding area, minimizing heat transfer and providing protection to nearby materials. In conclusion, fiberglass fabric is highly esteemed for its exceptional fire resistance properties, making it a preferred choice in industries such as aerospace, automotive, construction, and firefighting.

- Q:Can fiberglass fabric be used for hoses?

- Fiberglass fabric can be used for hoses in certain applications. While traditional hoses are typically made of rubber or plastic materials, fiberglass fabric can be used as a reinforcement layer in hose construction. The fiberglass fabric provides strength, durability, and resistance to high temperatures, making it suitable for applications such as high-pressure water hoses, chemical hoses, or industrial hoses that are exposed to extreme conditions. However, it is important to note that fiberglass fabric alone may not be sufficient to create a functional hose, and it may need to be combined with other materials, such as rubber or thermoplastic, to provide flexibility and leak resistance. Ultimately, the specific requirements of the hose and the intended application will determine whether fiberglass fabric is a suitable choice for its construction.

- Q:Large screen whole electric lift screen, PVC good or glass fiber?

- If the effect of a long decline, it depends on how long the time is really down, both can not escape the fate of decline.

- Q:How is fiberglass fabric used in the military industry?

- Fiberglass fabric is commonly used in the military industry for its lightweight and durable properties. It is utilized for various applications such as ballistic protection, reinforcement of structures, insulation, and as a component in the manufacturing of military vehicles and aircraft. Additionally, fiberglass fabric is employed in the production of protective clothing and equipment for military personnel.

- Q:Can fiberglass fabric be used for insulation in construction projects?

- Indeed, insulation in construction projects can utilize fiberglass fabric. Constructed from interwoven glass fibers, this material boasts remarkable thermal insulation capabilities. It finds extensive application in walls, roofs, and floors, effectively impeding heat transfer and enhancing energy efficiency within buildings. Its lightweight nature, flexibility, and ease of installation contribute to its widespread adoption in construction endeavors. Moreover, fiberglass fabric's resistance to fire, moisture, and chemicals renders it a sturdy and enduring insulation material.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

FRP Pultrusion Roof Tile Sheets or Panels

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500M2 m²

- Supply Capability:

- 900M2/Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords