Coatecd Fiberglass Fabric with Different Specification

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

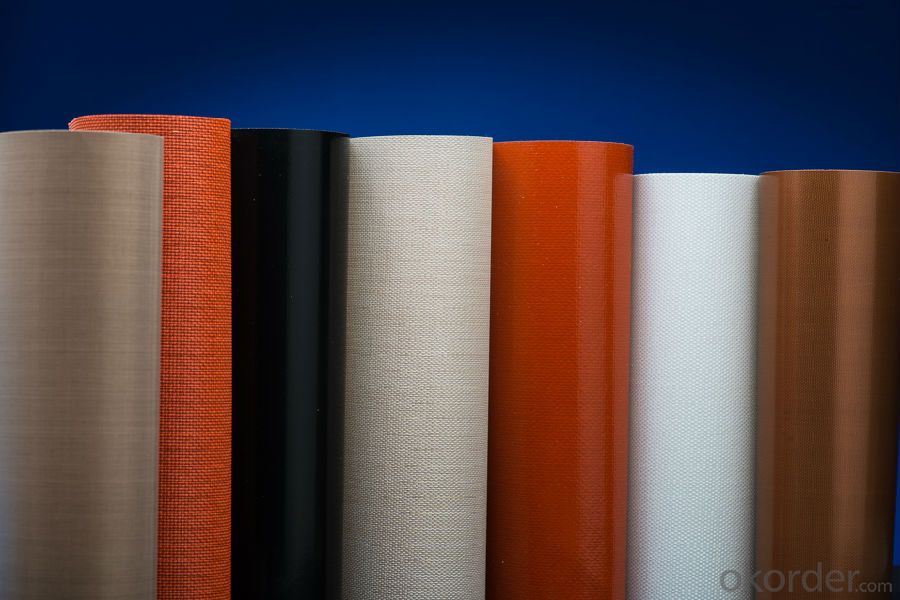

Coatecd Fiberglass Fabric with Different Specification

Fiberglass Fabric Description

Silicone coated fiberglass fabric are made of fine fiberglass with excellent capacity of high temperature and corrosion resistance, coated and rolled with silicone rubber, which is a brand new product with good performance and multiple applications.

Fiberglass Fabric Specification

Thickness:0.2mm-5mm

Width:100cm-150cm

Color;grey/red/silver/black

Weight(coating):130gsm-2800gsm

Model No | FSD2030 | FSD2030 | FSD2050 | FSD2100 | |

High temperature resistant(°C) | ≤280 | ≤280 | ≤280 | ≤280 | |

Low temperature resistant(°C) | ≥-40 | ≥-40 | ≥-40 | ≥-40 | |

Tensile intensity (N/50mm) | Warp | ≥1750 | ≥1750 | ≥2500 | ≥3500 |

Weft | ≥1280 | ≥1280 | ≥2100 | ≥3000 | |

Inflating burst intensity(Mpa) | ≥2.0 | ≥2.0 | ≥2.2 | ≥2.6 | |

Peeling intensity(N/m) | ≥450 | ≥450 | ≥520 | ≥600 | |

Insulation (kv/mm) | 16 | 16 | 18 | 18 | |

Weight (g/m*m) | 550-650 | 550-650 | 750-800 | 1500-1800 | |

Width(mm) | 1000±20 | 1000±20 | 1000±20 | 1000±20 | |

Thickness(mm) | 0.3-0.4 | 0.3-0.4 | 0.05-0.55 | 1.0-1.1 | |

color | Silver-gray, gray, red | lucency | Silver-gray, gray, red | Black, gray, red | |

Fiberglass Fabric Features:

1, Good performance on resisting high temperature and low temperature, -40°C-280°C;

2, High strength;

3, Ozone, oxide, light and weather aging resistance;

4, High insulation: dielectric constant:3-3.2, breakdown voltage: 20-50KV/MM;

5, Chemical corrosion resistant, oil-proofing, waterproofing (washable)

Fiberglass Fabric Application:

1) Electric insulation: it feature high grade of electric insulation and bear a load of high voltage. It fits for making products like insulation cloth and sleeves et.

2) Non - metalli compensator: used as pipeline oupling, non-metallic compensactor helps to avoid damage caused by heat expansion and cold contraction. This membrane material speially fit for using in industres of petroleum, chemical engineering, cement, iron and steel and good elasticity and toughness.

3)Anti-conrrosion sector: It is good to be used as inner and outer anti-corrosion layer featuring excellent corrosion resistance, tempareture resistance and high strength. It proves to be an ideal anti-corrosion material.

4) Others: Apart from above application, it can also be used as sealing material, temperature resistant and anti-orrosion conveyr belt and packaging material.

Product Show

FAQ

1.What are the characteristics of fiberglass fabric?

a)Outstanding temperature resistance(from -70°C to +260°C)

b)Excellent chemical resistance

c)Superior non-stick surface, easy to clean

d)High dielectric strength

e)Dimensional stability

f)Resistance to UV, IR and HF

g)Non-toxic

2.How many methods to weave the fabric?

Four methods to weave the fabric:

a).Plain weave: it can be used in electricity insulation materials and reinforced materials in industry, because of inseparable structure, plain and clear lines.

b).Twill weave: compared with plain weave, it is of high density, high intensity, with a soft and loose structural weave. It can be used in ordinary reinforced materials, filter materials, and painting cloth.

3.Can you offer us some samples?

We are willing to offer our customers best product&service,if it's necessary we can send

you sample for test;also we welcome all you customer have a trial order.

- Q:Can fiberglass fabric be used for making shower curtains?

- Absolutely! When it comes to making shower curtains, fiberglass fabric is a stellar choice. Renowned for its durability, water resistance, and effortless upkeep, it's an ideal material. This fabric resists mildew and mold, which are frequent concerns in bathrooms, and can withstand the moisture and humidity found in shower areas. What's more, fiberglass fabric is a breeze to clean and doesn't absorb water, preventing saturation or unpleasant odors. All in all, opting for fiberglass fabric to create shower curtains ensures a lasting and hygienic solution for any bathroom.

- Q:Is fiberglass fabric easy to clean?

- Yes, fiberglass fabric is easy to clean. It can be wiped clean with a damp cloth or sponge, and for more stubborn stains, it can be spot cleaned with mild soap and water.

- Q:Can fiberglass fabrics be used for reinforcement in plastic products?

- Yes, fiberglass fabrics can indeed be used for reinforcement in plastic products. Fiberglass fabrics are known for their high strength and durability, making them an excellent choice for reinforcing plastic materials. The fiberglass fabric is typically impregnated with a resin, which when cured, creates a strong and rigid composite structure. This reinforcement helps to improve the mechanical properties of the plastic product, such as increasing its tensile strength, stiffness, and impact resistance. Additionally, fiberglass fabrics offer excellent dimensional stability and resistance to chemicals, making them suitable for a wide range of plastic applications. Overall, fiberglass fabrics are a popular choice for reinforcing plastic products due to their superior strength and performance characteristics.

- Q:What is the advantage of coating waterproof layer with matrix reinforcing material?

- A large area of matrix can enhance the tensile strength of waterproof coating. Some asphalt and modified asphalt waterproof coating have low tensile strength after film forming. Therefore, we must add non-woven fabrics or fiberglass cloth to enhance the tensile strength of waterproof film.

- Q:Can fiberglass fabric be used for insulation in industrial ovens?

- Yes, fiberglass fabric can be used for insulation in industrial ovens. Fiberglass fabric has excellent thermal insulation properties, making it a suitable choice for insulating high-temperature environments like industrial ovens. It helps to retain heat within the oven and prevents heat loss to the surroundings, thereby enhancing energy efficiency and reducing operating costs. Additionally, fiberglass fabric is resistant to heat, fire, and chemical exposure, making it a durable and safe option for insulation in industrial ovens.

- Q:Can fiberglass fabric be used for insulation in mining operations?

- Fiberglass fabric has the capability to be utilized as insulation in mining operations. Its remarkable thermal insulation properties are widely recognized, rendering it a suitable choice for various applications, including mining operations. By effectively capturing and inhibiting the transfer of heat, it contributes to maintaining a consistent temperature within mining environments. Furthermore, the high temperature, corrosion, and chemical resistance of fiberglass fabric make it particularly well-suited for the frequently encountered harsh conditions in mining operations. Its lightweight and flexible characteristics also facilitate easy installation and handling in diverse mining structures and equipment. In summary, fiberglass fabric presents itself as a dependable and efficient solution for insulation in mining operations.

- Q:Is fiberglass fabric suitable for high-temperature applications?

- Indeed, fiberglass fabric proves to be fitting for high-temperature applications. It possesses durability and heat resistance, allowing it to endure temperatures reaching 1000°F (538°C). Notably, fiberglass fabric boasts exceptional insulation properties, rendering it an optimal selection for heat-related applications, including insulation in ovens, furnaces, and industrial equipment. Moreover, its superior strength-to-weight ratio and ability to resist chemicals and abrasion establish it as a dependable choice for environments with elevated temperatures. Nevertheless, it is worth mentioning that the temperature range and capacities of fiberglass fabric may fluctuate contingent upon the grade and quality of the material.

- Q:Can fiberglass fabric be used for insulation in telecommunications infrastructure?

- Yes, fiberglass fabric can be used for insulation in telecommunications infrastructure. Fiberglass fabric is known for its excellent thermal insulation properties, making it an ideal choice for insulating various components in the telecommunications industry. It can effectively prevent heat loss or gain, ensuring that the equipment operates within the desired temperature range. Fiberglass fabric is also lightweight, flexible, and easy to install, making it a convenient option for insulating cables, antennas, and other infrastructure components. Additionally, fiberglass fabric is resistant to moisture, chemicals, and fire, providing an added level of protection to the insulation system. Overall, fiberglass fabric is a suitable and widely used material for insulation in telecommunications infrastructure.

- Q:Can fiberglass fabrics be used for reinforcement in composites?

- Composites utilize fiberglass fabrics for reinforcement purposes. These fabrics consist of woven or knitted strands of glass fibers, renowned for their remarkable tensile strength and stiffness. They are frequently employed as reinforcing materials during the manufacturing processes of composites. Composites refer to materials created by amalgamating two or more dissimilar materials, resulting in a novel material with enhanced properties. Fiberglass fabrics are typically combined with a matrix material, like epoxy resin, to form a robust and lightweight composite structure. The utilization of fiberglass fabrics as reinforcement in composites offers several benefits. Firstly, they exhibit exceptional durability and mechanical properties, including high tensile strength and stiffness. Consequently, they are suitable for applications necessitating a high strength-to-weight ratio, such as the aerospace, automotive, and marine industries. Furthermore, fiberglass fabrics possess the capability to be easily molded into intricate shapes, making them versatile for various purposes. They also exhibit resistance to corrosion, in addition to possessing commendable thermal and electrical insulation properties. Moreover, fiberglass fabrics can be customized to meet specific design requirements by adjusting the orientation of the fibers, fabric weight, and resin system. This allows for the optimization of strength, stiffness, and other mechanical properties, depending on the intended application. In conclusion, fiberglass fabrics are widely used as reinforcement in composites due to their exceptional strength, lightweight nature, durability, and versatility. They provide numerous advantages and are an indispensable component in the manufacturing of sturdy and lightweight composite structures across various industries.

- Q:Can fiberglass fabric be used for insulation in tanks and vessels?

- Yes, fiberglass fabric can be used for insulation in tanks and vessels.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Coatecd Fiberglass Fabric with Different Specification

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords