ZNSJ brick forming pallet brick production pallet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

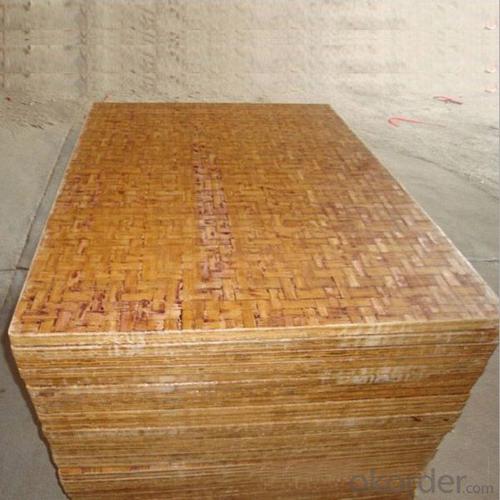

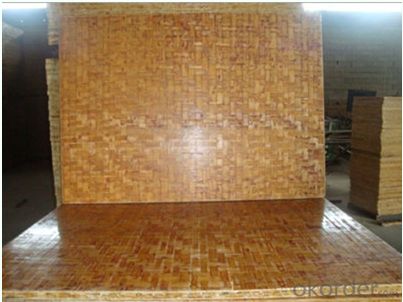

ZNSJ brick forming pallet brick production pallet

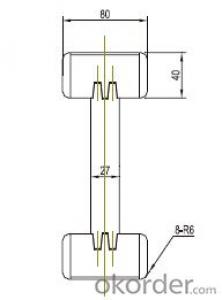

Dimension of ZNSJ brick forming pallet brick production pallet:as per customer requirement, the normal thickness are 20mm,25mm,30mm.

Application of ZNSJ brick forming pallet brick production pallet: baking-free brick bamboo pallet is used as supporting plate for baking-free brick

Product introduction of ZNSJ brick forming pallet brick production pallet:

baking-free brick bamboo pallet use high quality bamboo splint through weaving and dry processing, and then, using special phenolic glue dipping and drying again, at last via large tonnage hot-press machine with high temperature and high pressure made .

Product Advantages of ZNSJ brick forming pallet brick production pallet:

Bamboo pallet have the characteristics of wide width, light weight, high strength, small deformation, wear-resisting, high temperature resistant, waterproof, antifreeze, anti-corrosion, long life and so on. Its superior mechanical properties and considerable economic benefit makes it a new generation upgraded products to wood pallet, steel pallet, plastic pallet and rubber pallet, it is the first selection of baking-free brick production supporting pallet.

Items | Parameters |

Product Name | Pallet,Bamboo Pallet ,Bamboo Pallet for Brick Machine, Bamboo BlockPallet,bamboo formwork, bamboo board, bamboo pannel, |

Specifications | 1250*950*30(mm) as for customer’s requests |

Glue | Phenolic Glue |

Materials | Bamboo |

Moisture Content | 10% |

Density | 800~950kg/m3⊥ |

Modulus Of Elasticity | ≥6×103N/mm2 ≥3.5×103N/mm2 ≥5×103N/mm2 ≥3×103N/mm2 |

Modulus Of Rupture | ≥70N/mm2 ≥40N/mm2 ≥55N/mm2 ≥35N/mm2 |

Impact Strength | ≥60Kj/m2 |

Bonding Strength | ≥0.80N/mm2 |

Abrasion Value | ≤0.80g/100r |

Preservation Stregth | //≥60N/mm2 ⊥≥40N/mm2 |

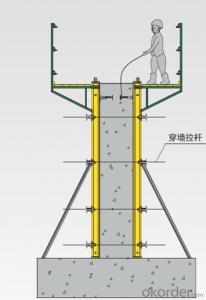

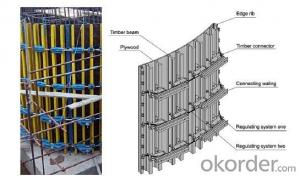

- Q: What is the use of building wall formwork support? Thank you

- In the construction for concrete cast-in-place construction formwork supporting structure, widely used in steel or timber beams assembled into the template bracket

- Q: Technical specification for construction formwork safety JGJ162-2008 who has made me please

- Template design and construction, from the actual situation of engineering, reasonable selection of materials, scheme and construction measures; should satisfy the template in the transport, installation and use of the strength, stability and stiffness requirements, and should give priority to the finalization, standardization and template template support components, reduce production and installation workload. To improve the reuse rate.The design, manufacture, installation and removal of the 1.0.4 construction formwork shall be in conformity with the requirements of this code, and shall comply with the relevant provisions of the state.

- Q: 1, JGJ162-2008 construction formwork safety technical specification;2, JGJ130-2011 construction fastener type steel pipe scaffolding safety technical specifications; the friend has. Send me thanks

- 3 2.1.12 flying die flying shuttering mainly by the platform board, support system (including beam, support, support, legs, etc.) and other accessories (such as lifting and walking mechanism, etc.). The utility model is a large tool type template, which is called a table mould or a table model because of the appearance of the utility model. Because it can take advantage of lifting machinery, pouring from the well under the floor of the lift out of the transfer to the upper layer of repeated use, so called flying mode. 2.1.13 tunnel mode tunnel shuttering a combination of stereotypes template, while pouring concrete wall and floor of the template, because the shape of the template like a tunnel, it is known as the tunnel model.

- Q: 86335 template support, what is the concept of those advantages

- 86335 new formwork support structureDigital steel formwork support composite structureAt present, in the construction for concrete cast-in-place construction formwork supporting structure, widely used in steel or timber beams assembled into the template bracket, built into the scaffold to form a bracket supported by steel or wood, and with steel formwork concrete construction. The problem is to build and assembling workload, low construction efficiency, labour and material consuming and poor quality, waste of resources, not beautiful and difficult to adjust

- Q: Since the building, and I would like to ask some of the basic knowledge to the construction of a unified drawing, plus or minus 0 and the height of the drawings, the roof slope requirements. Now the blue steel reinforced concrete inclined roof beams or do. Here we use multiple beams, and the waterproof, thermal insulation, in tile. Anyway, many shortcomings is wood, attic space basically scrapped, there is a fire started...I would also like to use concrete flat top, that is, do not let, more depressed.If I can use wooden beams, waterproof SBS, hanging plastic extruded board?The construction of plastic extruded board in inclined roof beams hung strong? Construction is not difficult?As well as the 8X11 meters of the roof, 30 degrees slope, sloping roof concrete cost about? I feel modeling and cloth reinforcement are very troublesome, expensive cost estimation

- You can put the beam properly after the play flowers on top, which is the slope of the wall, so that you can

- Q: What is the building template support

- (1) the material of the template support: high performance cold rolled steel, thickness of 2.5 mm to 2.7 mm, the new material is characterized by: corrosion resistance, elasticity, strong deformation.(2) the specification of new steel building formwork support:

Send your message to us

ZNSJ brick forming pallet brick production pallet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords