XPS Foam Board Extruding Machine/XPS Foam Board Production Line/XPS Extruder

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product introduction

Extruder/Screw And Barrel for Extruder/Plastic Extrusion

Screw Diameter 55 to 65mm

30 to 100 KG/HR

AC20 to 40HP/11.5 to 15KW

Reference Values

| CMAX series twin-screw extruder | |

| Mixing modification | PE,PP,PS+SBS,PA+EPDM,PP+NBR,NVA+silicon rubber,etc |

| PE,PA,PC,CPE+ABS(ALLOY),ABS+TPU,PBT+PET,PE+PP,etc | |

| Filling modification | PE,PP,EVA,etc+Calcium carbonate,talcum power,titanic powder, |

| ABS,PC,PS,etc+aluminum hydroxide,magnesium hydroxide,antimony oxide | |

| PP,PA,ABS+ferrous powder,sulphuric powder,ceramic powder | |

| Functional masterbatch | PP,PA,ABS,PBT,etc+burning agent and other auxiliary agents: combustion-supporting machine pellets |

| PP,PE,PS etc+starch:de-composing machine pellets | |

PE+fog-preventing dipper,stabilizer: dual-prevention machine pellets | |

| PE,EVA,ABS+carbon black:black machine pellets | |

| Colored masterbatch | PE,PP,ABS,AS,PA,EVA,PET+pigment and auxiliary |

| glass fibers/ carbon fibers reinforcement | PP,PBT,ABS,AS,PA,PC,POM,PPS,PET,etc+long fibers, small fibers,carbon fibers,crystals and so on |

| Various cables | HDPE,LDPF,LLDPE,MDPE,EVA,PVCetc+Insulating cables, coatings,PE peroxide,silicon alkyl crossing cables |

| Special materials | EVA heat-melting glue,polyurethane,fluorin rubber,fluorin plastics, PP cigarette filtering material and TPR sole material |

| Reaction extruding | Polyamide condensate,polyamide melting polymerization, polyamide polyethrne-adding,polycarbonate condensate,etc |

| Exhausting and Volatilization | Polystyrene oxide,high-absorbing resin,chlorine sulphur polyethylene |

| Powder paint | Polyester,ring oxide,lactide,polyurethane,acrylate |

Application

a Masterbatch

b Plastics modification

c Fiber glass reinforcement

d Cable compounds

e Alloy plastics

f Powder coating and toners, etc

Features

1. Screw components designed by computer aids is kneading type, has excellent self-cleaning function,

the new kneading block design effectively avoid the problems of overheating and energy consumption.

2. According to process system and formula requirements, the unit can optimize its L/D ratio, barrel structure, screw array,

venting number and location, feeding method, electrical control methods etc. for rational allocation.

3. Granulation system: water-cooling strand pelletizing, air-cooling die face hot cutting, water ring die face hot cutting,

Eccentric water mist hot cutting, water and underwater die face hot cutting and so on.

4. Application: Filling Modification, glass fiber (carbon fiber) enhance various kinds of master batch,

rubber and plastics compounding, plastic alloys, functional master batch, Various kinds of electric cable material,

reactive extrusion. Devolatilization process, powder coating and so on..

Advantages

The meshed structure screw has excellent mixing and plasticazation ,comparing with other type extruder.

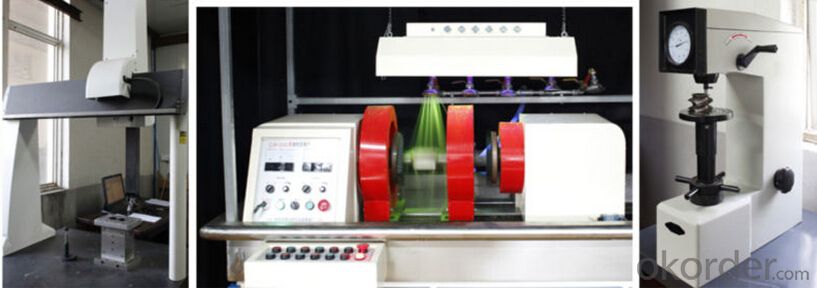

Product show

FAQ

PVC sheet extrusion

*Q: What’s the price of this machine please?

*A: Dear customer, for each kind of our machines, we have lots of models.

Generally speaking, we design the production lines according to

different requirements of different machines from different customers.

Therefore, the prices are different. So please kindly inform us your requirements.

For example, the raw material, the output product size, capacity and etc.

The more detailed, the better. Our Engineers will design a suitable production line for you.

- Q: Why is the connection between the extruder and the switchboard?. The upper and lower three terminals are short circuited

- The action should be to require three simultaneous electricalOr a two way backup

- Q: Can PC and PP be extruded together with two materials in an extruder?

- No co extrusion, PC polycarbonate, PP polypropylene, two kinds of product structure is not the same, not the same chemical composition, viscosity and liquidity is not the same, processing temperature and processing technology is also very different, and two kinds of products, so not incompatible, CO extrusion.

- Q: What raw material does the extruder use?

- Control science and EngineeringJob: in gender: Male College: College of mechanical and power engineering representative paper: melt rotating twin screw extruder in conveying flow solving teaching: research direction: mainly engaged in polymer material processingLinear low density polyethylene (LLDPE) linear low density polyethylene (LLDPE) linear low density polyethylene is structurally different from the generallow density polyethylene

- Q: PVC extrusion machine extrusion stone floor no pressure, what reason?

- PvC stone floor extruder pressure is adjusted by the screw and die head

- Q: 1: what is the difference between an extruder and an injection molding machine?Answer the questions in terms of structure, process, product difference, material distinction, mould distinction and development areaThis is a kind of mechanical professional mold mold equipment on an essay question, please the professional teacher to help answer, thank you very much, the students have urgent need, thank you!!

- 2: injection molding machine, mainly to melt the plastic injection molding process, after the mold injection molding machine outjection. The main products are mechanical parts, containers, household appliances shell.

- Q: Extruder price

- According to the size of the screw, single and double screw configuration is different, there are many different prices between fifty thousand to two hundred thousand, we specialize in the production of extruders, crushers and mixing machines, high quality and low price, contact information on the user name

- Q: Why single screw extruder is controlled by high school and low?

- I feel like I didn't explain the problem

- Q: why production is not strong?I have several new co extrusion machines, but the blown plastic bags are not produced by others

- Tensile strength is divided between longitudinal and transverse, and PE bags are transversely increased, available 8CLLDPE is added, longitudinal can be added to medium, medium density or high-density material to increase tensile strength.

- Q: The working principle of an extruder

- What is the working principle of an extruder?:Screw with specific shape,Turn in a heated barrel,It will be delivered from the hopperThe plastic is pressed forward, allowing the plastics to be uniformly plasticized (i.e., melted)Through the head and different shapes of the mold, the plastic extrusionA continuous plastic layer of various shapes, extruded on the core and cable.

- Q: What are the components of an extruder?

- The driving system of an extruder is to drive the screw, providing the torque and speed required by the screw in the extrusion process, usually consisting of an electric motor, a reducer, and a bearing.3. heating and cooling device for extruderHeating and cooling are necessary conditions for the process of making a plastic extruder. It includes two aspects:(1) now host extruder is usually divided into electric heating, resistance heating and induction heating, heating installed in the fuselage, neck, head of each part. The heating device heats the plastic in the outer barrel to increase the temperature required for the process operation.(2) the cooling device is designed to ensure that the plastic is in the temperature range required by the process. Specifically, to eliminate the excess heat generated by the shear friction of the screw rotation, in order to avoid the temperature is too high, so that plastic decomposition, coke burning or stereotypes difficult. Cylinder cooling water cooling and air cooling is divided into two kinds, small and medium sized extrusion machine adopts air cooling is more appropriate, large use more water or two kinds of combined cooling; cooling water cooling screw mainly adopts the center, the purpose is to increase the solids conveying rate, stable glue volume, and improve product quality; but in the cooling hopper one is, in order to strengthen transport of solid material, prevent warming plastic sticky jam outlet, two is to ensure the normal work of the transmission part.

Send your message to us

XPS Foam Board Extruding Machine/XPS Foam Board Production Line/XPS Extruder

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords