Dow Xps 250 Blue Board - XPS Cement Insulation Board for Shower Room CNBM Group

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Insulation & waterproofing solutions - XPS cement insulation board for Shower Room CNBM Group

Product name XPS cement insulation board for Shower Room CNBM Group:

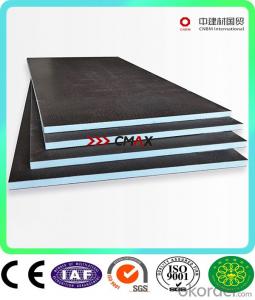

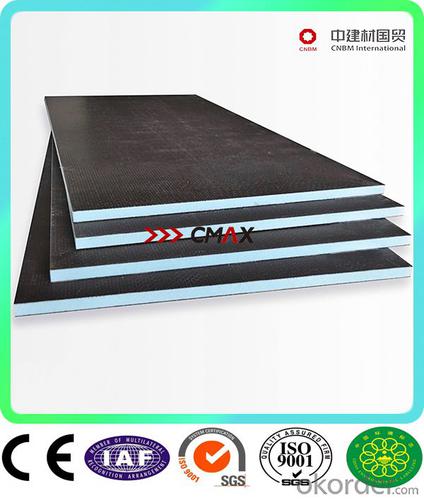

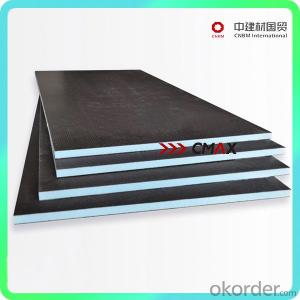

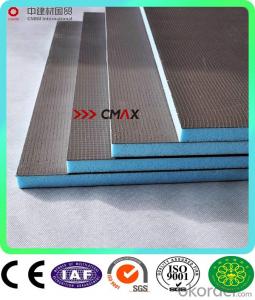

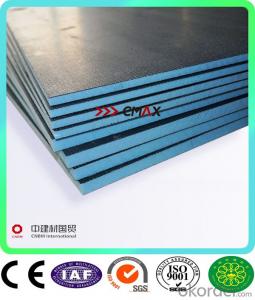

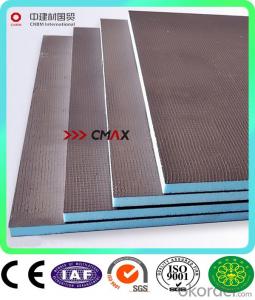

CMAX board (as known as construction board, tile backer board, insulation backer board, waterproof backer board, wet room backer board, XPS board.)

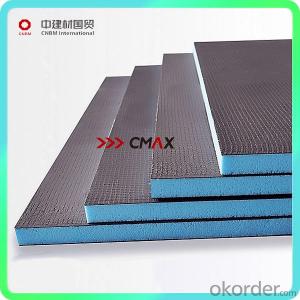

Product structure:

CMAX boards are made of high-performance waterproof extruded polystyrene (XPS Board), it has a 0.75mm coating on either side comprising a glassfiber mesh embedded in a polymer cement mortar.

Outstanding characteristics XPS cement insulation board for Shower Room CNBM Group:

Both insulation and waterproof.

Product appearance XPS cement insulation board for Shower Room CNBM Group:

The boards have straight edges. The color of the surface is grey and the core material is light blue.

Working temperature range XPS cement insulation board for Shower Room CNBM Group:

50 to +80 °C

Standard dimensions and weight XPS cement insulation board for Shower Room CNBM Group:

Thickness(mm) | Weight(kg/m²) | Length by width(mm*mm) |

6 | 2,7 | 1200 x 600 |

10 | 2,9 | 1250 x 600 |

12 | 3,0 | 2500 x 600 |

20 | 3.1 | 2500 x 600 |

30 | 3,3 | 2500 x 600 |

50 | 4,2 | 2500 x 600 |

The board has the following tolerances:thickness:± 2mm width:± 2mm length:± 3mm.

Reaction to Fire:

The boards are classified as class E according to EN 13501-1. When the boards are covered with tiles, their fire performance should comply with local construction laws and regulations.

Effect on indoor environment:

CMAX board has been assessed as not emitting any particles, gases or radiation that may have a negative effect on the indoor climate or to have any significant effect on health.

Environmental declaration:

The product does not contain any substances on the observation list of dangerous substances published by the national environmental authorities.

Main applications:

Used as a watertight layer on walls and floors in houses, hotels and other wet areas such as bathroom, shower room.

Other applications:

Other places to be insulated and waterproofed.

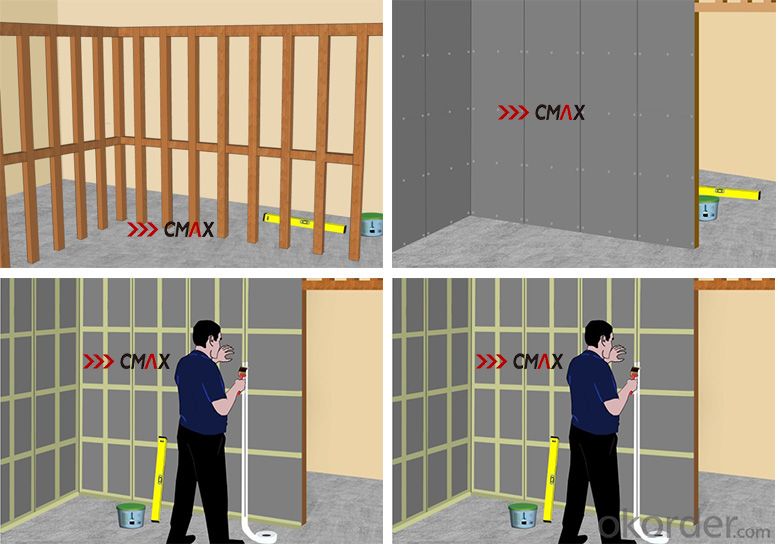

Applications:

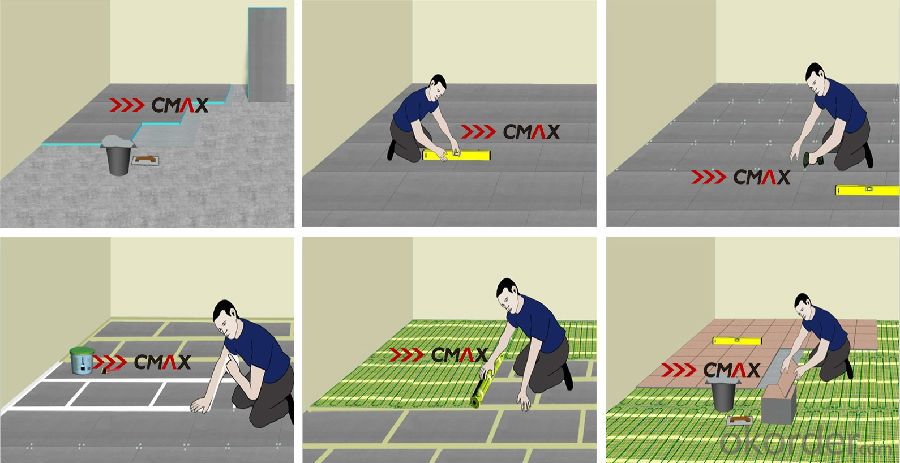

1. as a watertight layer on walls and floors in wet rooms and bathrooms.

2. as an insulation layer in under floor heating to avoid heat loss.

3. as partition walls in wood or steel frames.

4. substitute for gypsum board and fiber cement board; insulation and waterproofing; lighter so that more easily to install.

5. As enclosures for bathtubs, water pipes, etc.

6,Can very easily and fast formed to be small shelves, washbasins, shower benches and soap boxes.

7. Combining with CMAX curved/shapeable boards, kinds of decorative models can be made with your infinite creativity.

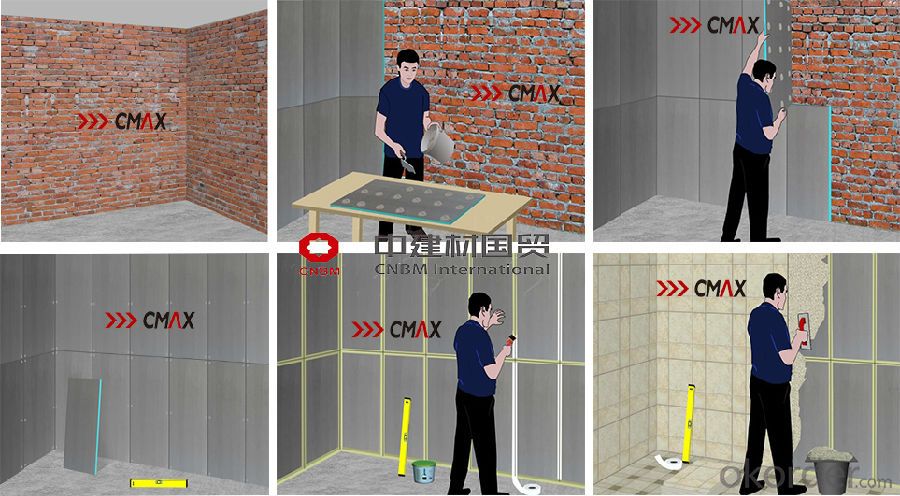

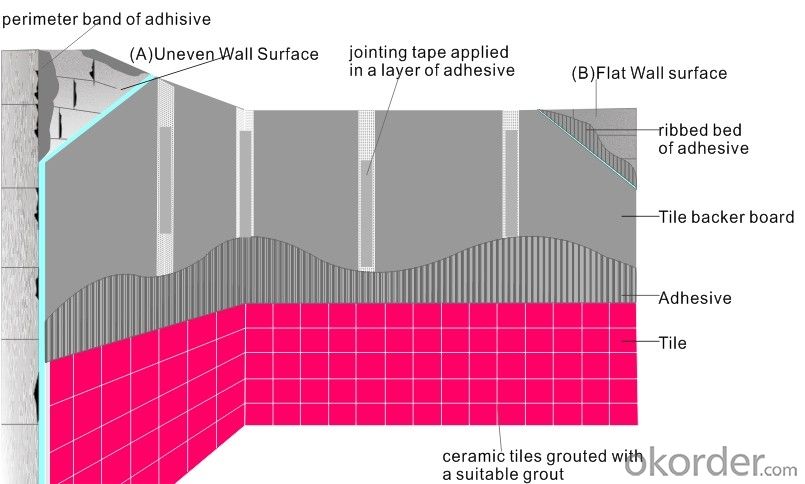

Fixing:

Choose a way to fix CMAX board according to the substrate to be fixed. Normally, using modified tile adhesive for solid concrete wall/floor and strengthened by mechanical fixings when necessary while only using mechanical fixings for wood and steel frames.

Reinforcement:

1. Dry areas: reinforce all joints between boards, floors and walls by 125px or 250px wide self-adhesive tape.

2. Wet areas: reinforce by suitable waterproof tape.

Waterproof strengthen:

1. Strengthening all joints between boards, floors, walls and mechanical fixings placements by suitable waterproof tape.

2. Strengthening joints between walls, outside corners and inside corners by special corners.

3. Sealing pipe holes with special waterproof tape.

4. Strengthening once again by waterproof glue, liquid tanking membrane, tanking membrane paint, etc. when necessary.

Coating of panels:

Should always be covered by ceramic tiles, mosaics or other equivalent non-fireproof materials after installation.

FAQ:

1.

Q: Are you a manufacturer of insulation materials?

A: Yes. ourselves manufacturer of thermal insulation board.

2.

Q: What is the seaport near your plants?

A: The nearest port is Shanghai Port, there are about 100km from the port to our plant in Shanghai.

3.

Q: What is annual production capacity of your main products?

A: 200,000 piecs per month.

4.

Q: Do you have your own brands? And what are they.

A: Yes. we are a fortune 500 company, our brand is "CMAX"

5.

Q: Is sample available for testing?

A: Yes. The sample is free.

We do OEM as well. Welcome to make an enquiry and we will give you quick response in 12 hours!

- Q: What is the difference between extruded polystyrene board and XPS insulation board?

- Is a normal phenomenon, frost in the frost when the frost, and a temperature probe.

- Q: Roofing the top of the extruded polystyrene insulation board generally how much weight ah?

- Metal hose is an important connection in engineering technology, from the corrugated flexible tube, mesh sets and joints combined. China in 1993 issued a national standard "corrugated metal hose general technical conditions" (GB / T-93). Metal hoses are made of austenitic stainless steel or according to the material required by the user. It has excellent softness, corrosion resistance, high temperature resistance (-235 ℃ ~ + 450 ℃), High pressure (up to 32MPa), in the pipeline can be connected in any direction for temperature compensation and absorption of vibration, reduce noise, change the direction of media transmission, to eliminate the pipe or between the pipe and mechanical displacement between equipment, Lan metal corrugated hose for a displacement, vibration of the various pumps, valves and other flexible joints is particularly applicable. Metal hoses use two kinds of bellows, one is a spiral corrugated tube; the other is a ring bellows. Spiral bellows The spiral bellows is a tubular shell with a corrugated spiral and has a helix angle between adjacent two corrugations. All corrugations can be connected by a helix. Ring bellows Corrugated tube is corrugated closed ring shaped tubular shell, wave and wave from the ring ripple in series. The ring bellows is machined from a seamless pipe or welded pipe. By the processing mode, compared with the spiral corrugated pipe, the length of a single tube is usually shorter. The advantage of the ring bellows is good elasticity and small rigidity. If you need to provide detailed advice, please call 0317-, Xinlong bellows will be happy to serve you.

- Q: Why extruded board (XPS board) is the best insulation board material

- Should belong to the template and support system. Full scaffolding is generally used for single-storey building, hall and other high-rise, large building between the top of the building decoration. By the pole, cross bar, bracing, scissors and other components.

- Q: I set up in October 2008, the production of XPS board - that is, with the extinction of polystyrene foam plastic plate, is an energy-saving environmental protection materials. Consult experts: I can enjoy the relevant tax incentives?

- the inner wall insulation, as the name suggests is the wall inside the house Hu Dangan citrus spinning song dead building, the use of spraying, bonding, pouring, etc

- Q: Roof insulation layer is extruded polystyrene foam plate how set the amount of set

- The honeycomb structure of the thick plate, there is no gap, this closed-cell structure Insulation materials can have different pressures (150-500Kpa) at the same time have the same low value of the thermal conductivity (only 0.028W / MK) and enduring excellent insulation and compression performance, compressive strength up to 220-500Kpa.

- Q: Steel plant wall plug color steel tile, the glass glass inside the glass, hanging in color steel, how construction? How is the cost associated with a single sandwich panel?

- More than 24 meters need to use cantilevered scaffolding, and the spacing of not more than 20 meters

- Q: Polystyrene foam hard insulation board will not be harmful to the human body, right?

- Building safety production management issues, please choose the answer (multiple choice)

- Q: The traditional ceramic insulation board, the existing thermal insulation coating in addition to the process and the construction period there are similarities and differences there are differences? Which energy-saving building is better?

- Single-row fastener type steel pipe scaffold for decoration works in the construction of small horizontal bar spacing should be the number of mm.........................................................

- Q: What is the difference between an extruded board and an XPS extruded board?

- Foam plastic plate insulation effect, hinder the outdoor temperature affect the indoor temperature, can play the role of Dongnuanxialiang. . the snow has the role of heat insulation, isolated 礌 礌 礌 蕺 蕺 蕺 蕺 scrapped wheat and outside the air contact, on the one hand to prevent the wheat freeze and death, on the other hand have the effect of refrigeration . to the thicker glass When the water is turned down, the inner glass is exposed to rapid heat, and the outer glass is in contact with the cold air of the cup, so that the expansion of the inner and outer walls causes the difference.

- Q: How to distinguish between good and bad insulation board insulation board

- Class flexible management refers to the class teacher in the student's psychological and behavioral laws on the basis of the use of non-mandatory way, in the minds of students to produce a potential persuasive, the use of the class teacher's own positive factors to influence and guide students

Send your message to us

Dow Xps 250 Blue Board - XPS Cement Insulation Board for Shower Room CNBM Group

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords