WAM Trough Screw Conveyors for Flour Mills MSC

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

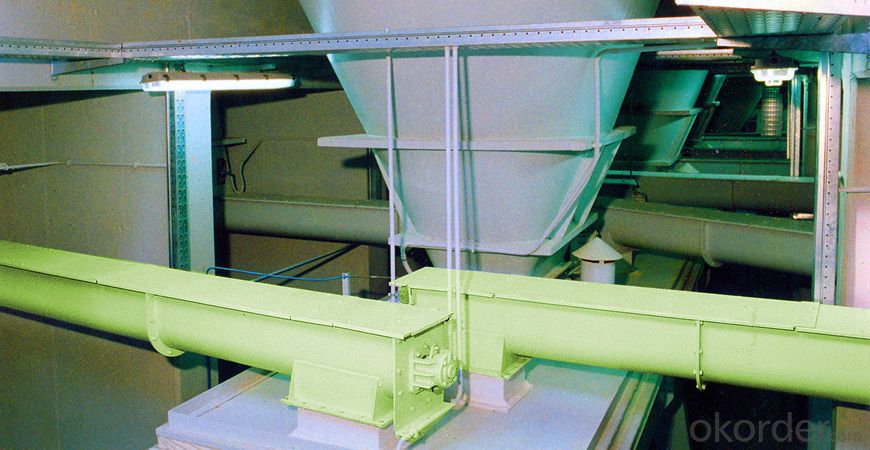

MSC Trough Screw Conveyors are a specialised version of the CA modular trough screw conveyor system. They are used in the flour milling industry, especially for conveying cereal grains, flour, and by-products such as bran. MSC Screw Conveyors are manufactured from carbon steel with food-grade surface finishing. They are made up of a U-shape trough equipped with at least one outlet spout, an end plate at each trough end, helicoid screw flighting welded on a centre pipe with coupling bush at each end, two end bearing assemblies complete with shaft seal, a number of intermediate hanger bearings with self-lubricating bushes depending on the overall length of the screw conveyor, as well as bolted trough covers. Furthermore, MSC Trough Screw Conveyors are equipped with a gear motor that suits the application.

MSC Trough Screw Conveyors come in a light-duty design only and they are available with ATEX, Zone 22 certification.

Function

MSC Trough Screw Conveyors are designed for handling powdery or granular materials in flour mills. Their design, their special finishing grade, and the vast range of options and accessories take the requirements of the flour milling industry into particular consideration.

Features

Light-duty trough in modular flanged sections manufactured from carbon steel

Light-duty helicoid flighting welded on centre pipe manufactured from carbon steel

Powder-coated

Square or rectangular inlet and outlet spouts with integrated drilled WAM standard flanges

Robust cast iron body flanged end bearing assemblies with external bearings and manually adjustable packed gland seals

Maintenance-free intermediate cast hanger bearings with self-lubricating slide bushes

Splined or bolted shaft couplings

Direct drive in a compact version, or with coupling transmission, or with chain or belt transmission

Food-grade finishing and surface painting

Benefits

Short delivery time due to modular design and availability of all components

Perfectly matching spare parts

Industrial quality design

Options

Twin or multiple shaft screw conveyors

Additional inlets and outlets

Trough feet

Overflow hatches

Drop bottom troughs

Tubular trough inserts

Trough covers with spring locks

Variable pitch or paddle type screws

Internal food-grade painting

MSC TROUGH SCREW CONVEYORS ARE AVAILABLE WITH ATEX, ZONE 22 CERTIFICATION

Send your message to us

WAM Trough Screw Conveyors for Flour Mills MSC

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords