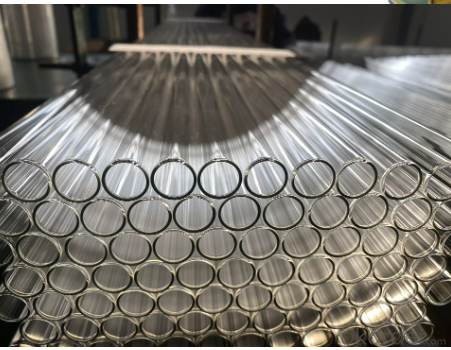

USP/EP Type I pharmaceutical amber glass tubing for vials and ampoules

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 2500 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

USP/EP Type I pharmaceutical amber glass tubing for vials and ampoules

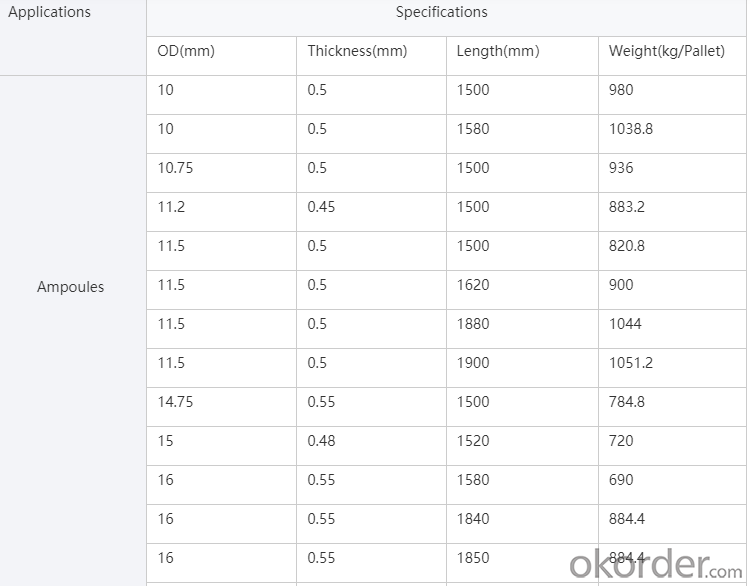

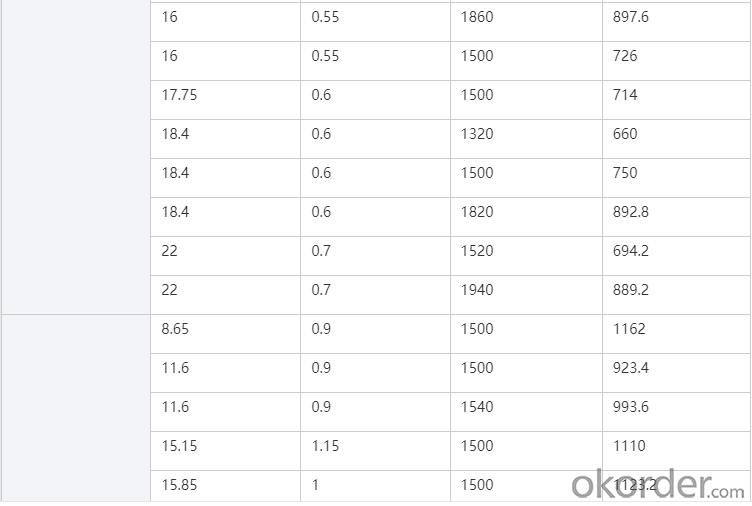

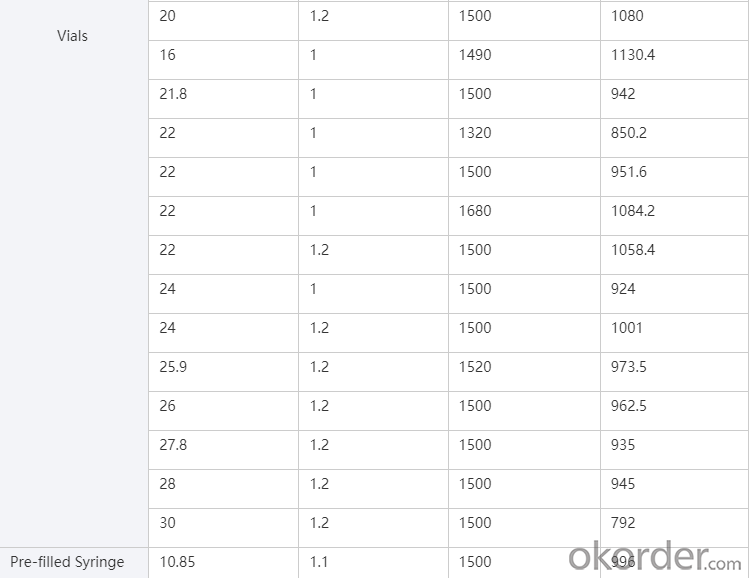

Specifications:

5.0 PHAEMACEUTICAL GLASS TUBES

5.0 neutral borocalicate glass is superior to 7.0 low borrocilicate glass comparing the aspects of hydrolitic resistance ,acid and alkali resistance ,anti-freezing,thermal stability,filling speed and others,which is not easily to get delamination due to inmersion and erosion of drugs itself,and is worldwide recognized saft pharmaceutical packaging materials.

TYPE I BOROCILICATE GLASS TUBES

The stability of the drug is change by the influence of temperature,hummidity,aair,light and microoorrganism.The borosilicate glass is

widely used in the field of pharmaceutical packaging as its charactetristics of long-term safety,has been used as a compulsory

primary packaging of injection and lyophilized drugs with an an irreplaceable staus.

Company Profile

We are China based manufacturer of USP/EP type I pharmaceutical glass tubing and bottles.CNBM international corporation mainly engage in export business of CNBM group thata state-own fortune 500 company.

CNBM business involved in cement,concrete,special glass,fiberglass products etc.And it integrates R&D,manufacturing and circulation.Our pharmaceutical glass factory located in Wei county,Heibei province.

With our efforts to develop the market domestic and abroad, we have built cooperation and partnership with 1600 manufacturers in China, and have established stable business relationship in more than 120 countries and regions abroad. CNBM International Corporation is an important member of the Logistics Trade Section of CNBM Group provides complete range of materials products, including decorative materials, insulation materials, waterproofing materials, refractories, fiberglass products,glass etc. Our exportation volume of fiberglass roving and strands is listed top 3 among the export traders in China.It integrates R&D,manufacturing and circulation.Our neutral botocilicate glass factory is specialized in designing ,research,macnufacturing and trading of USP Type I neutral borocilicate glass tubes and bottles.We has been tested by the National Inspection Agency-Beijing Drug Packaging Test Institute.It is fully complies with the stabdards of EP,USP,JP,ISO12775 and the standard of YBB00012005-2-2015 ect.It has reached the international evel in expansion coefficient,content of boron of boron and hydrolitic resistane and other performance index ,it can help the socity for drug safty and healthy life.

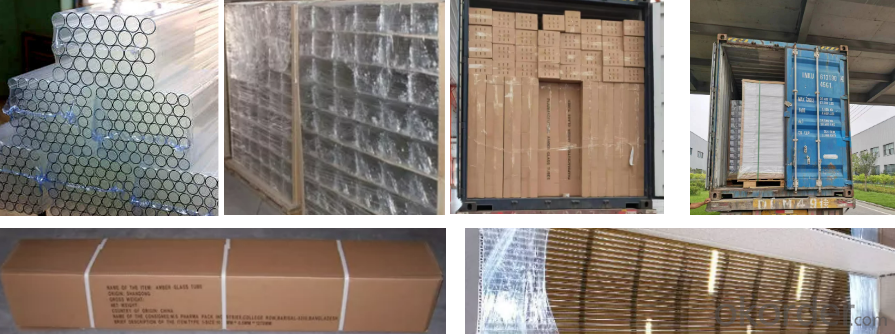

Packing and Delivery

Delivery:Rush Order in 5-10 days for small order

FAQ

1) Can we get your free samples?

Yes, you can. Our Samples are only free for the customers who confirm order. But the freight for express is

on buyer's account.

2) Can we combine many items size in one container in my first order?

Yes, you can. But the quantity of each ordered item should reach our MOQ.

3) What is the normal lead time ?

A. We will send goods to you within 15-35 work days after we receive your 30% deposit.The detail is based on the current

production schedule.

4) What is your shipping way?

We will help you to choose the best shipping way according to your detail requirements.

By sea, by air, or by express, etc.

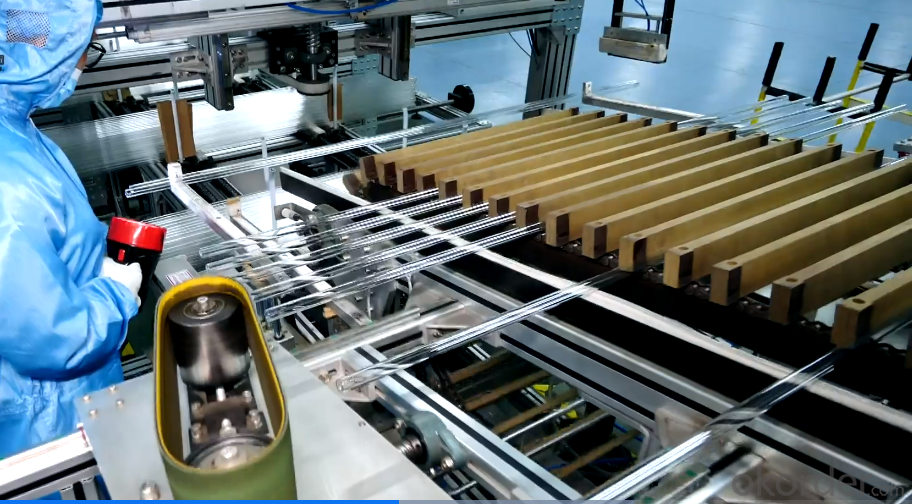

5) How do you control the quality?

We will make samples before mass production, and after sample approved, we will begin mass production.

Doing 100% inspection during production; then do random inspection

before packing; taking pictures after packing.

6) If any quality problem, how can you settle it for us?

If any breakage or defect products were found, you must take the pictures from the

original carton. All the claims must be presented within 7 working days after discharging

the container. This date is subject to the arrival time of container.

We will advise you to certify the claim by third party, or we can accept the claim from the

samples or pictures you present, finally we will completely compensate all your loss.

- Q: Paper bags, milk and plastic bags. What's the difference between milk and paper bags?

- Paper packaging bags - paper bags are sealed and filled with milk, which is poured into the paper tube and then cut and sealed, so there is no air in it. The paper bag is composed of paper, aluminum, plastic six layer composite packaging, can effectively put the milk and air, light and bacteria isolation, so it can be stored at room temperature, and longer shelf life, can reach 45 days, paper bags of the higher price, the cost is low.

- Q: What are the packing materials for heavy cargo transportation?

- The bulky goods need to use fixed bandages, tie belt, to prevent the occurrence of collision in the process of transportation, damage. Dragon Century Logistics has made big transport in Hongkong, and the handling and strengthening of large cargo before shipment are more mature.

- Q: Billycan what are the advantages compared with other packaging materials?

- The decoration is exquisite: the metal material has good printing performance; the design trademark is bright and beautiful; the packaging container made by it is noticeable, and it is a kind of good sale packing.

- Q: What's the difference between bulk food and prepackaged food?

- Pre packaged foods mean foods that are prepackaged or packaged in pre packaged materials or containers. Generally speaking, the bulk food produced by small workshops does not count as prepackaged food.

- Q: What are the characteristics of paper holders in comparison with other packaging materials?

- The first is the protection of the environment, paper packaging raw material is waste paper pulp, not only has no pollution to the environment, but also conducive to conserve resources, protect the environment. The use range of paper tray is very extensive, with the improvement of technology paper,

- Q: What are biodegradable packaging materials?

- Biodegradable packaging has a bright future and has attracted worldwide attention. In this paper, the properties, degradation mechanism, processing technology and application of various kinds of degradable packaging materials are reviewed. According to the mechanism of degradation, it can be divided into biodegradable plastics, biodegradable plastics, light / biological double degradable plastics and water degradation plastics.

- Q: What are the common material choices, printing options and common sense?

- Health gift box: the use of 157G coated paper laminating grey board or board, can also be wove paper or other special craft paper.Printing: 4+0C printing, printing spot colors, gold or silver.After the process: light glue, matte plastic, local UV, matte, hot embossing, platinum (metallic film with gold, silver, blue and other colors for choice) or anti-counterfeit film (so that others can not copy), inner box (internal) model and separated model. The common silk cloth, sponge or foam mounted flocking plastic materials. The handicraft is elaborately done by hand. Selection of materials according to product needs and grades to choose, to ensure that the United States and the concept of economic and practical.

- Q: What advantage does PET material have in packing?

- As a packaging material, PET has good mechanical properties, and its impact strength is 3~5 times of that of other films. It has good folding resistance

- Q: Which industry does the packing product belong to?

- Other countries or organizations have different meanings and opinions about the meaning of packaging, but the basic meaning is consistent. They all take the function and function of packaging as their core contents and have two meanings in general:1. Containers, materials and auxiliary articles that contain the goods, that is, packages.2, on the implementation of containing and sealed, dressing and other technical activities.

- Q: How many kinds of packing are there?

- According to the number of packages used: once packaged, repeatedly packaged and returnable packaging;5. according to the degree of hardness of the packing container: hard packing, semi hard packing and soft packing;6., according to product categories: food packaging, drug packaging, mechanical and electrical products, packaging devices, dangerous goods packaging;7., according to functional categories: transport, packaging, storage, packaging and sales, packaging and so on;

Send your message to us

USP/EP Type I pharmaceutical amber glass tubing for vials and ampoules

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 2500 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords